Tipping paper coiling roller placing rack

A technology of placing racks and rolling rolls, which is applied to tool storage devices, manufacturing tools, etc., can solve the problems of inconvenient use, heavy weight, and the inability of placing racks to rise and fall, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

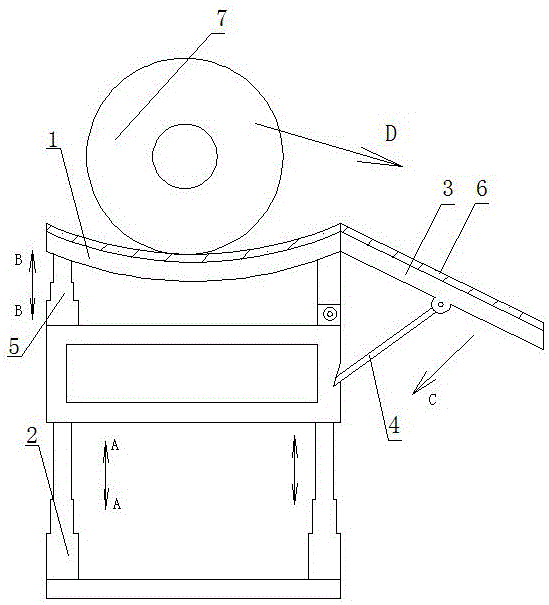

[0015] Such as figure 1 As shown, a tipping paper reel roll placement stand includes a placement stand body, and a placement plate 1 with an arc-shaped groove structure is arranged on the top of the placement stand body. A lifting device 2, the first lifting device can lift and lower the placement plate 1, and the first lifting device is an air cylinder or a pedal lifting component.

[0016] Like this, can lift when placing or taking off the paper reel roll 7 of tipping, easy to use, A among the figure is exactly the direction that the first lifting device lifts. D in the figure is the direction in which the tipping tray roll rolls down.

[0017] Further, there is a hinged extension plate 3 on the side of the placement plate, and a slope is formed after the extension plate is raised. After the extension plate is lowered, there is a hinged support between the extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com