Corner wrapping device of picture stretching machine

A corner-wrapping and stretch-painting technology, applied in special decorative structures, decorative arts, etc., can solve the problems of low processing efficiency, artificial corner wrapping, large manpower, etc., and achieve the effect of improving production efficiency and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

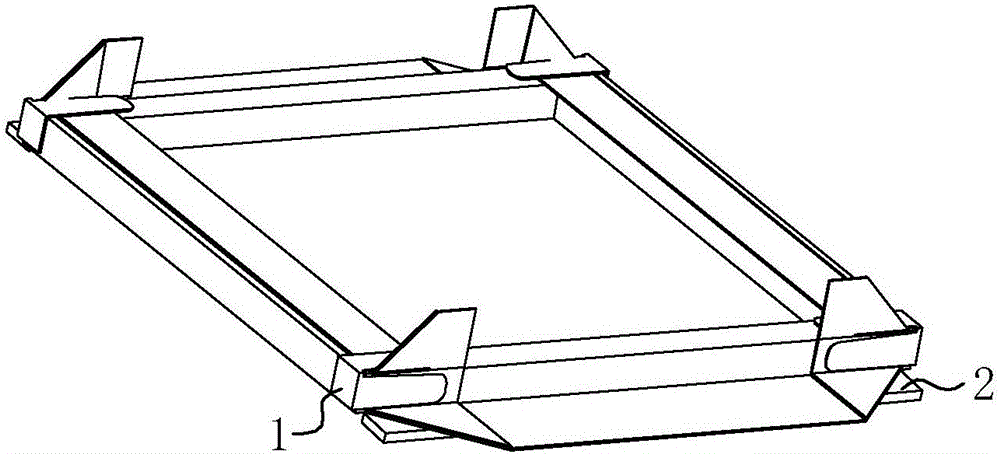

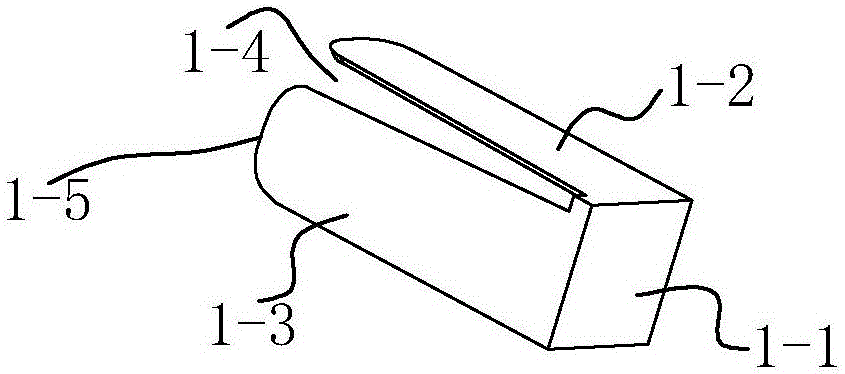

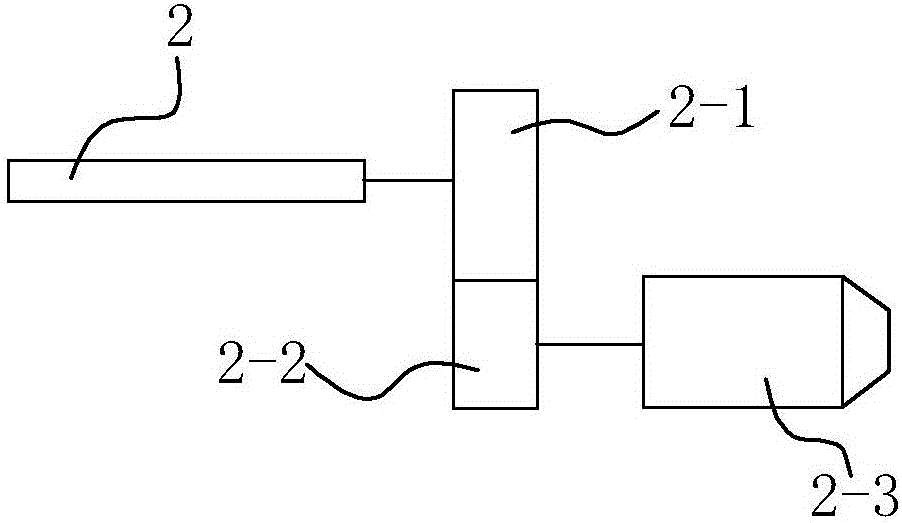

[0019] refer to figure 1 , a corner-wrapping device of a stretch painting machine according to the present invention includes a corner-wrapping fork 1 for folding corners and a turning plate 2 for flattening the corner-folded canvas, and the corner-wrapping fork 1 is connected with a drive corner-wrapping fork 1 The first driving device for the action, and the turning plate 2 is connected with a second driving device for driving the turning plate 2 to move. When the inner frame painting is made, the picture frame is placed on the back of the canvas. There are four sides of the picture frame that need to be nailed and fixed. Under the action of the first driving device, the fork 1 is nested on the corner of the inner frame, and the canvas on the side of the surface to be nailed is pressed tightly against the side, and then the turning plate 2 is under the action of the second driving device. Flip over, fold the protruding canvas on the side corresponding to the bottom surface,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap