Assembly method of vehicle bumper support, support body and fixing pin

A technology for automobile bumpers and fixing pins, which is applied in the field of auto parts, can solve problems such as inability to realize functions, and achieve the effects of firm fixing, easy disassembly, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described below in conjunction with specific embodiments.

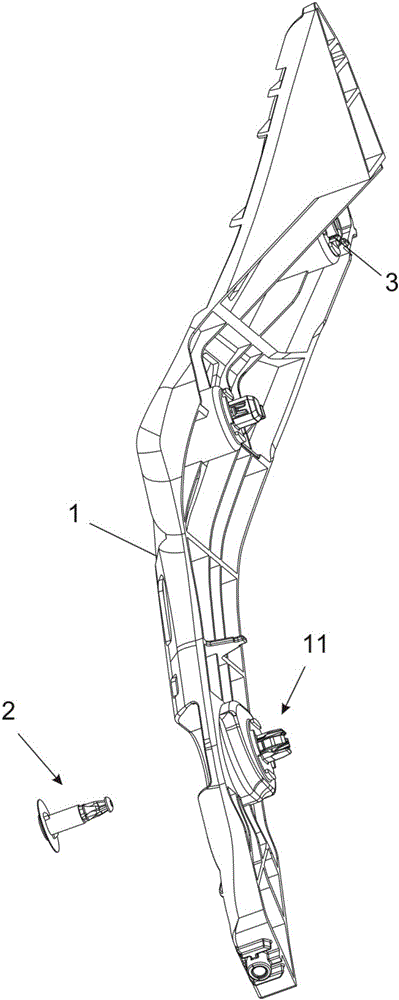

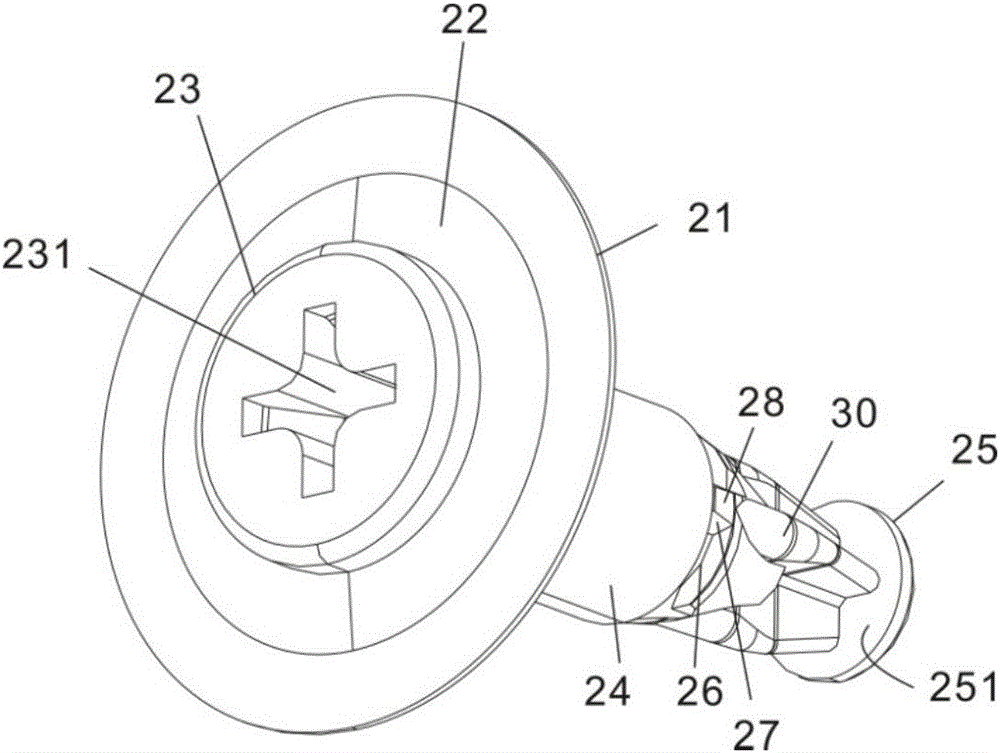

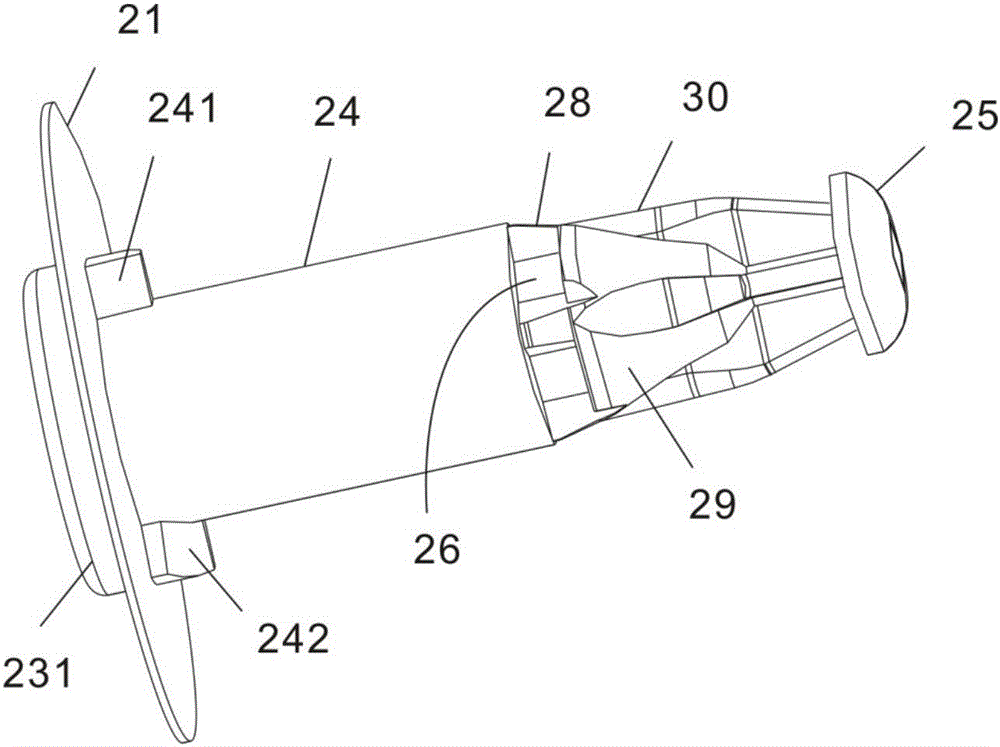

[0050] Such as Figure 1 to Figure 5 As shown, implement a kind of assembly method of automobile bumper bracket, described method comprises:

[0051] The first step is to first set a bracket body 1, the bracket body 1 includes an easy-to-detach fixing seat 10 on one side and a screw fixing hole 3 on the other side;

[0052] In the second step, a sunken top platform 12 is set on the easy-to-disassemble fixing base 10, and a limit block 13 is set on the top platform 12; a pin hole 14 is set in the middle of the top platform 12;

[0053]Then on the back side of the bracket main body 1, the corresponding fixed seat bottom surface 11 of the easy-to-detach fixed seat 10, the periphery extending from the pin hole 14, is provided with the elastic pin block 15 connected with the fixed seat bottom surface 11, the elastic pin block 15 There is a chuck 151 at the end;

[0054] Protruding ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com