Foam clamping groove for packaging PCBA board and manufacturing and use methods of foam clamping groove

A foam card and card slot technology, applied in packaging and other directions, can solve problems such as environmental damage and waste, and achieve the effects of serious waste, simple structure and reliable design principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

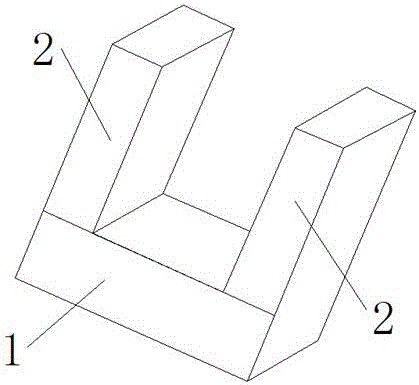

[0032] Such as figure 1 As shown, the present invention provides a foam card slot for packaging PCBA boards, which includes a base plate 1 and side plates 2, the side plates 2 are located at both ends of the base plate 1, and the base plate 1 and side plates 2 form a U Type slot structure, the bottom plate and the side plates are polyethylene foam boards, the bottom plate and the side plates are bonded together by hot melt adhesive, and the thickness of the bottom plate is greater than or equal to the thickness of the side plates.

[0033] In this embodiment, the polyethylene foam board contains antistatic material particles, so that the polyethylene foam board has an antistatic effect.

[0034] The polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com