A fast variable load control method for supercritical circulating fluidized bed boiler units

A circulating fluidized bed and supercritical boiler technology, which is applied in fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve problems such as large energy storage, improve stability, enhance comprehensive competitiveness, The effect of convenient engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

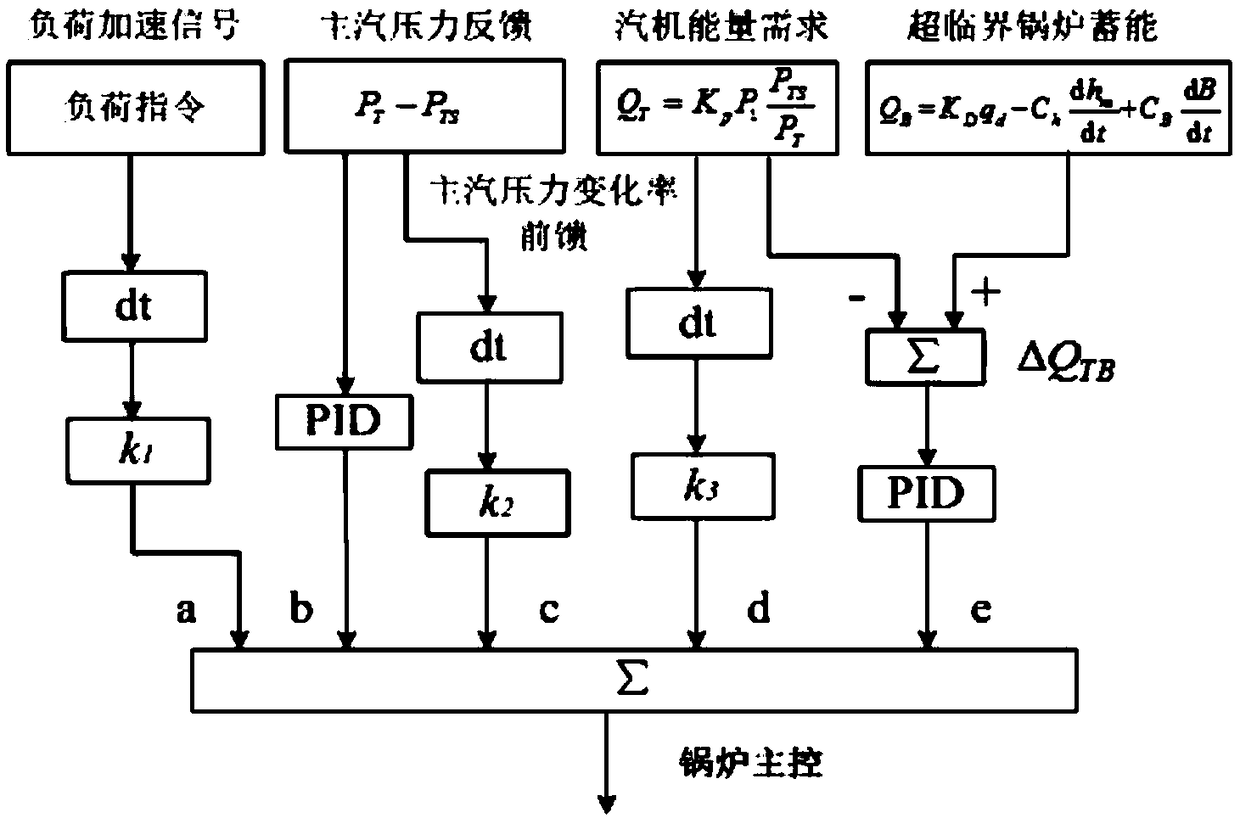

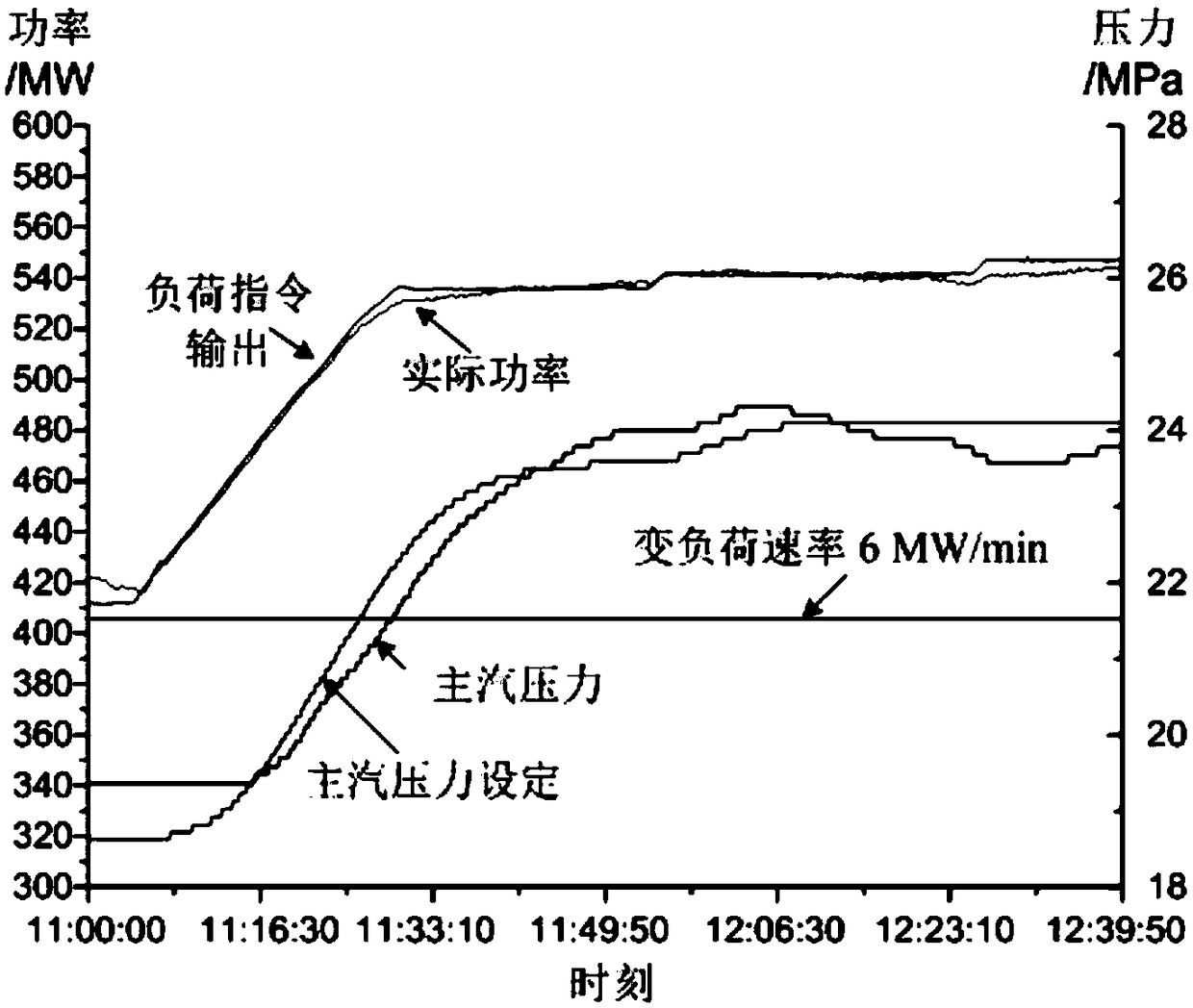

[0030] A method for fast variable load control of a supercritical circulating fluidized bed boiler unit, such as figure 1 shown, including the following steps:

[0031] S1, after the AGC scheduling instruction is differentiated, it is multiplied by k 1 Get the control sub-signal a, the k 1 is the conversion proportional coefficient between the control sub-signal a and the main control of the boiler;

[0032] S2, the deviation signal between the actual value of the main steam pressure and the set value of the main steam pressure is output by the PID controller to obtain the control sub-signal b;

[0033] S3, the main steam pressure is processed by the differential link and multiplied by k 2 Get the control sub-signal c, the k 2 is the conversion proportional coefficient between the control sub-signal c and the main control of the boiler;

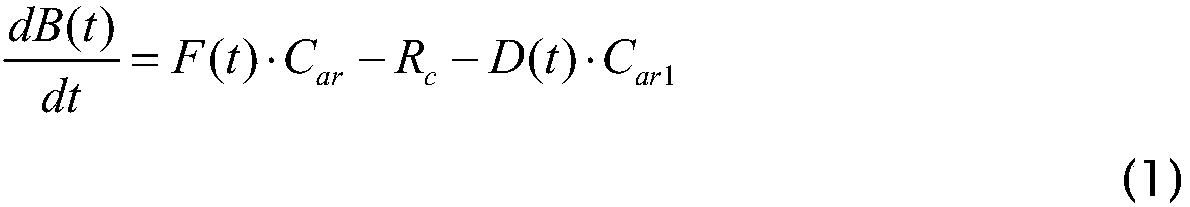

[0034] S4, main steam pressure, main steam pressure set value and steam turbine energy demand signal of machine front force structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com