Flexible lifting control method for thermal power generating unit

A technology of thermal power units and control methods, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as difficult realization of on-site actual processes, unstable renewable energy sources, and small load changes, and achieve load grid connection Problems, broad commercialization prospects, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

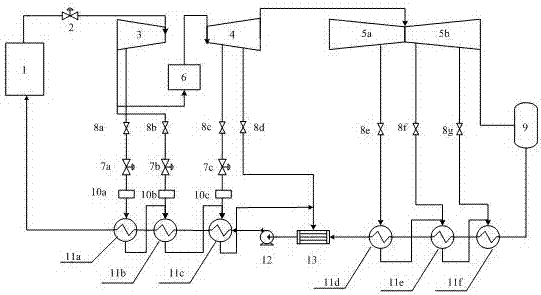

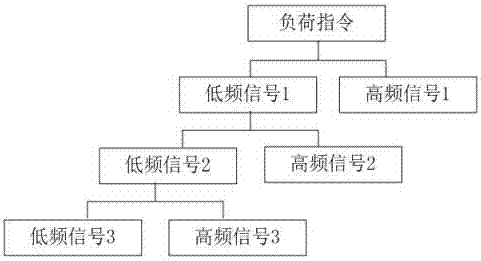

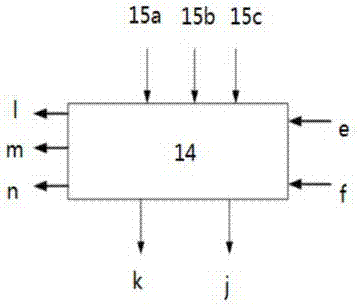

[0047] The following combination Figure 1 to Figure 7 The present invention will be further described in detail with specific examples, and the specific examples described here are only used to explain the present invention, and are not intended to limit the present invention.

[0048] refer to figure 1 , Both the high-pressure heater and the low-pressure heater of the steam turbine need to extract steam from the steam turbine to heat the boiler feed water. Since the enthalpy of the steam extracted by the high-pressure feedwater heater is relatively high, the ability to change the load of the steam turbine is relatively large. Install an electric regulating valve 7a on the pipeline connecting the steam extraction point of the first stage of the steam turbine to the No. 1 high-pressure feed water heater, and install a differential pressure flowmeter 10a behind the electric regulating valve; Install an electric control valve 7b on the pipeline of No. 1 high-pressure feed water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com