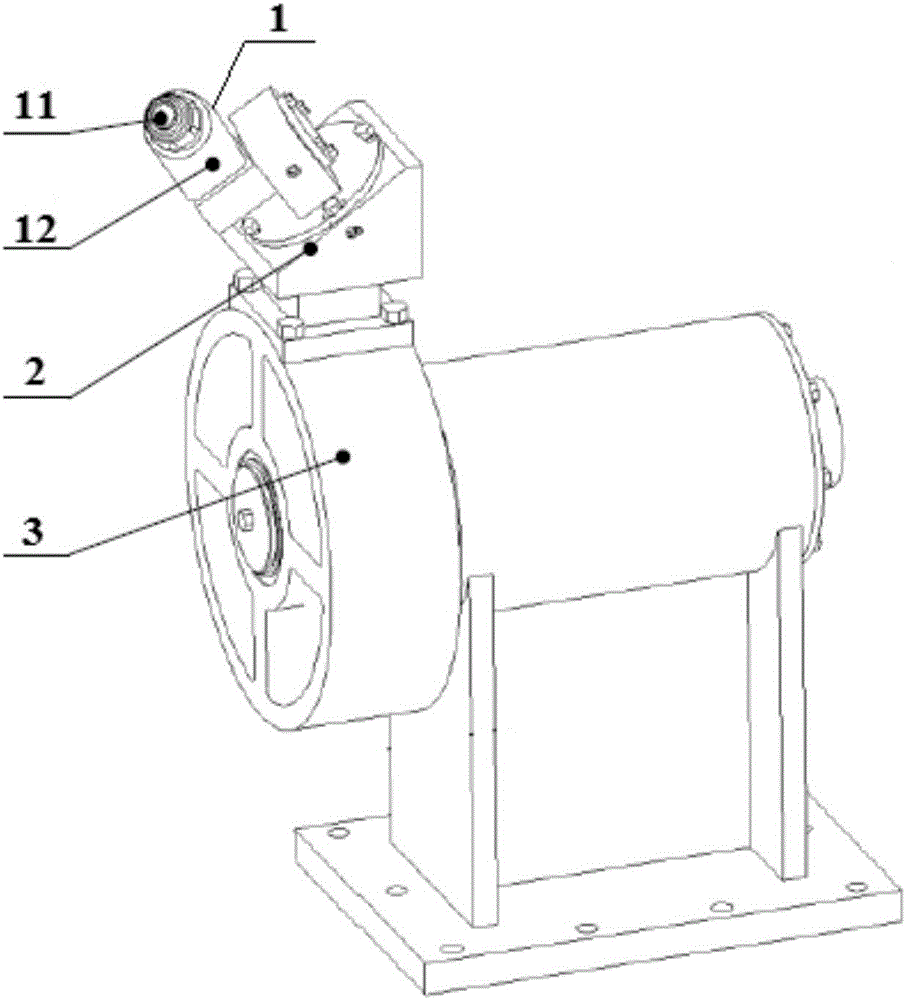

Cutting test device

A technology of cutting test and pick, which is applied in the field of cutting test, can solve problems such as the inability to effectively study the matching of pick installation parameters, and achieve the effect of improving operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

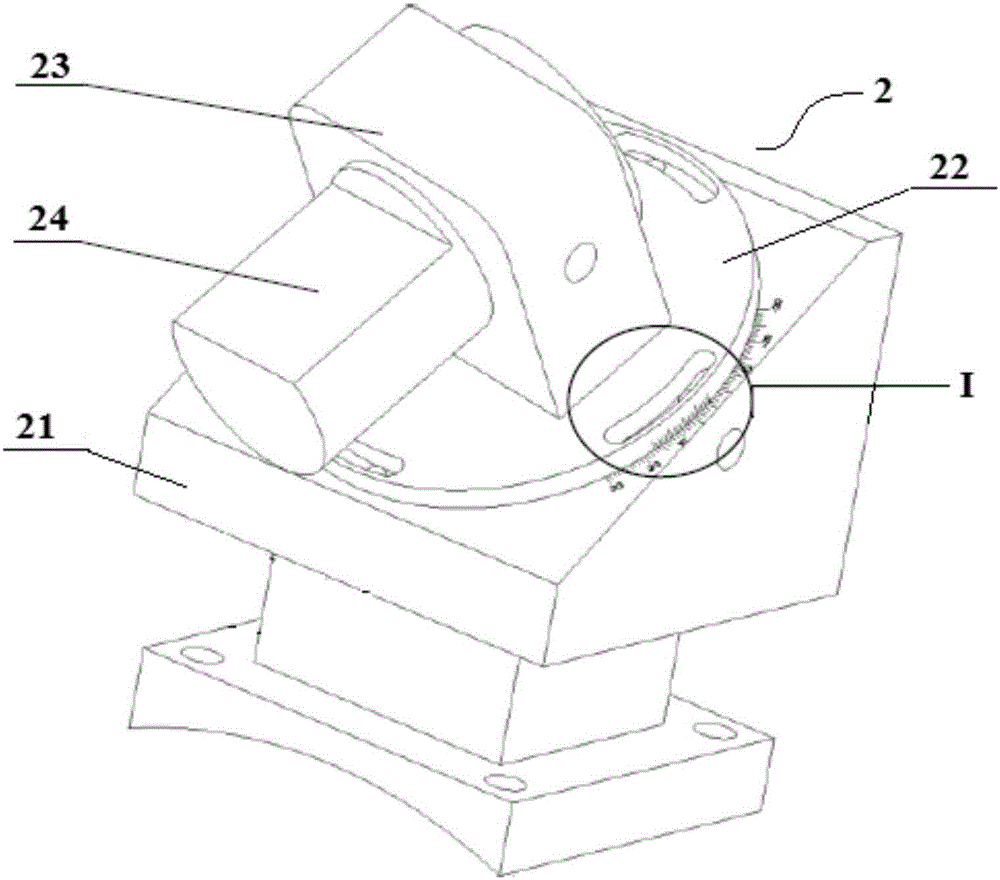

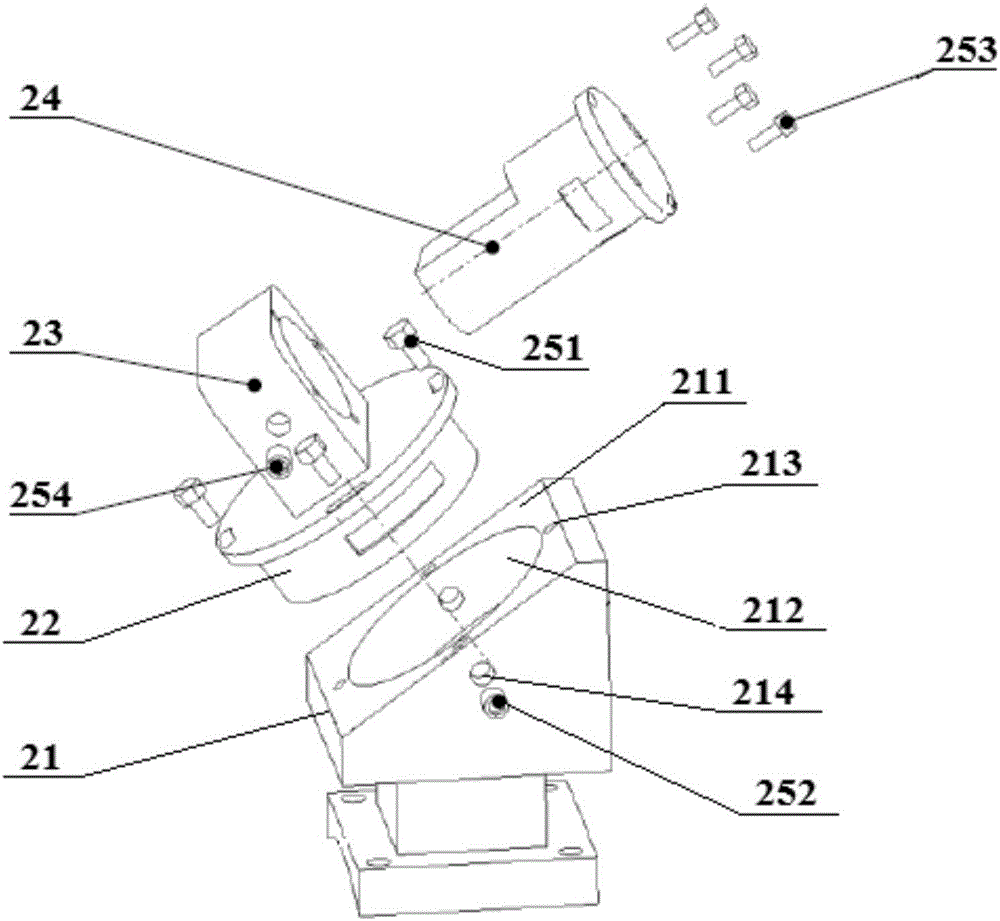

Embodiment approach

[0068] In order to further simplify the adjustment process of the elevation angle of the pick 11, in the present invention, the elevation adjustment mechanism can be arranged on the rotation angle adjustment mechanism, and after the rotation angle adjustment mechanism sets a certain rotation angle, the elevation angle adjustment mechanism is rotated relative to the rotation angle adjustment mechanism to adjust the elevation angle. Based on this, as an embodiment of the elevation angle adjustment mechanism of the present invention, the elevation angle adjustment mechanism may include a second reference part 23 and a second adjustment part 24, wherein: the second reference part 23 is arranged on the first adjustment part 22, and the second reference part 23 The second reference part 23 has a second axis parallel to the inclined plane 211 and perpendicular to the first axis; the second adjustment part 24 is used to install the cutting assembly 1, that is, the cutting installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com