Catchable packer blocker

A plug and packer technology is applied in the field of internal plugs for oil and water well maintenance under pressure operation, which can solve problems such as affecting the operation effect, inability to unpack, and stop blocking, so as to improve the efficiency of maintenance under pressure operation, The effect of improving the speed and efficiency of the operation and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

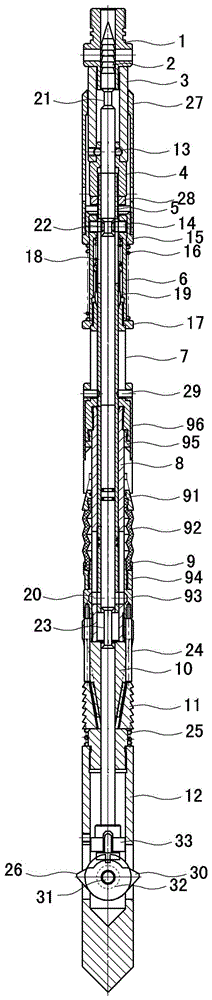

[0007] Such as figure 1 As shown, it includes upper joint 1, fishing rod 2, sliding sleeve 3, adjusting cap 4, middle sleeve 5, upper connecting sleeve 6, connecting sleeve 7, lower connecting sleeve 8, rubber cartridge assembly 9, slip seat 10, The slips 11 and the main body 12, the upper joint 1 is axially slidably fitted on the outside of the upper end of the fishing rod 2, the sliding sleeve 3 is located under the upper joint 1 and fitted on the outside of the fishing rod 2, the upper end of the sliding sleeve 3 is threaded with the upper joint 1 The lower end of the adjustment cap 4 is axially connected, the adjustment cap 4 is axially slid on the outside of the fishing rod 2, the upper end is set on the lower end of the sliding sleeve 3, and the position where the sliding sleeve 3 and the adjusting cap 4 are fitted is installed on the inner wall of the sliding sleeve 3 and The steel ball 13 in the steel ball groove on the outer wall of the adjustment cap 4, the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com