Resin piping with flow aids

A technology of auxiliary parts and pipes, which is applied in the field of resin pipes, can solve the problems of weak materials of flow auxiliary parts and cannot be supported by resin pipes, etc., and achieve the effect of rapid cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

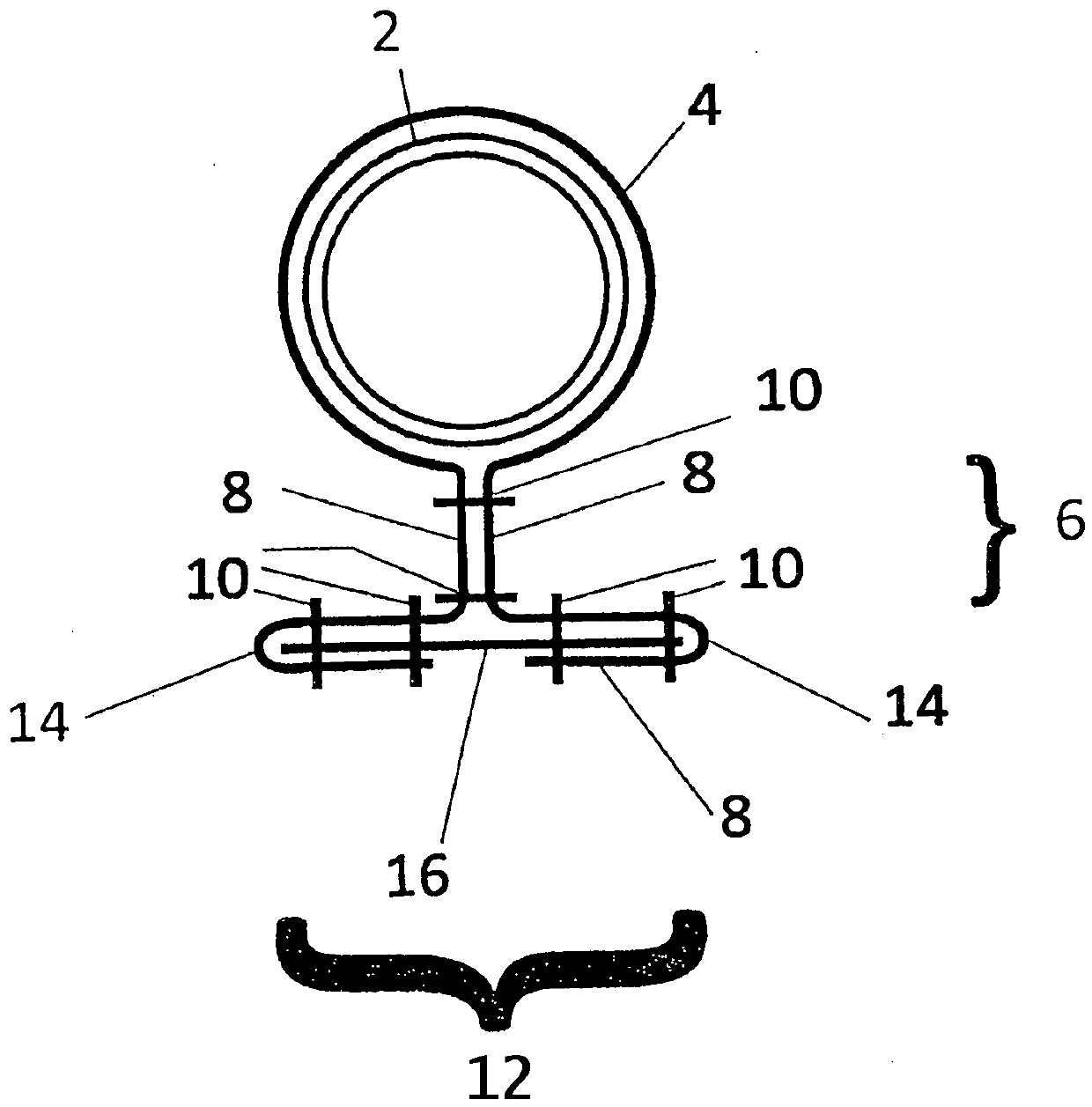

[0018] The present invention will now be described in more detail based on examples. The drawing shows a resin line 2 through which the matrix material is guided. The matrix material can penetrate from the inside of the resin line 2 to the outside through openings not further shown in the drawing. There, the matrix material comes into contact with the flow aid material 4 , which is arranged as a jacket around the resin line 2 .

[0019] The flow aid material 4 is dimensioned such that the tab 8 projects beyond the circumference of the resin line 2 beyond the circumference of the resin line 2 and forms a double-layer web 6 in a section. The two protruding tabs 8 of the flow aid material 4 are connected to one another in the region of the web 6 by the two shown stitched seams 10 .

[0020] At the end of the web 6 facing away from the resin line 2 there is a section 12 bent relative to the web. In the present embodiment, the bent section 12 comprises two rings 14 into which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com