Dual-purpose clamping device for internally supporting and externally clamping

A clamping device and dual-purpose technology, applied in the direction of the chuck, etc., can solve the problems of multiple times of clamping devices and low processing efficiency, and achieve the effect of solving frequent replacement and meeting the processing needs of small batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The dual-purpose clamping device for internal support and external clamp of the present invention will be described in detail below in conjunction with the drawings and embodiments of the specification:

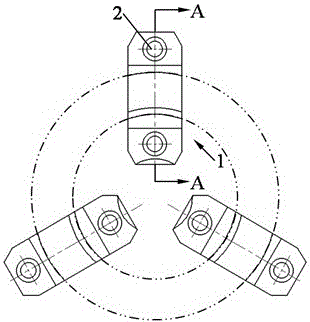

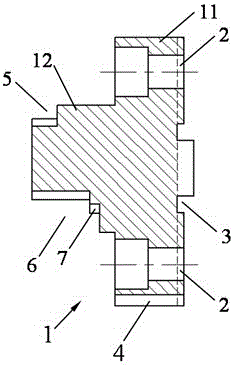

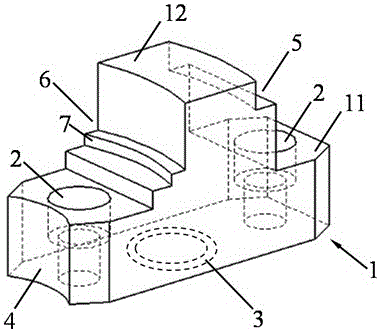

[0021] Such as Figure 1~3 As shown, a dual-purpose clamping device for internal support and external clamping includes three clamping assemblies 1 evenly distributed at intervals of 120°, and the clamping assembly 1 is a section formed by a shoulder 11 and a convex portion 12 It is a convex structure, the shoulders 11 on both sides form screw holes 2, and the bottom surface forms an annular slot 3; the outer wall of the convex part 12 forms an inner supporting concave platform 5, and the inner wall forms an outer clamping concave platform 6, and an outer clamping concave platform 6 A convex strip 7 is formed on the top; the side walls of the inner supporting concave platform 5 and the outer clamping concave platform 6 are circular arc surfaces protruding outward.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com