Supporting mechanism for steel pipe internal grinding

A support mechanism and round-grinding technology, which is applied to machine tools designed for grinding workpiece rotating surfaces, parts of grinding machine tools, grinding machines, etc., can solve problems such as waste, unusable grinding wheels, and inability to adapt to different diameters of grinding wheels, etc., to achieve The effects of extended service life, improved scope of application, and adjustable installation height

Inactive Publication Date: 2017-05-31

HUANGSHI CHENGDA PRECISION MACHINERY MFG

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is: in order to solve the problems existing in the above-mentioned background technology, provide an improved support mechanism for internal grinding of steel pipes, and solve the problem that the support sleeves currently on the market cannot adapt to grinding wheels with different diameters. Moreover, once the grinding wheel wears less than the specified size, it cannot be used, which is a very wasteful problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

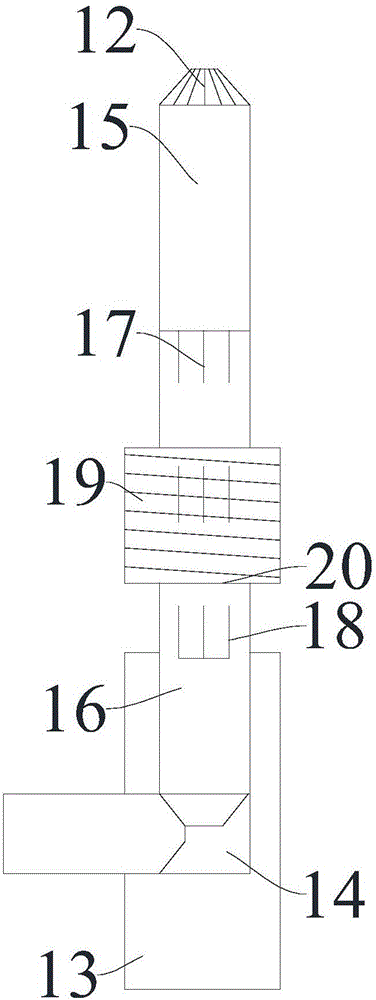

[0016] Embodiment: People can easily change the distance between the upper rotating shaft 15 and the lower rotating shaft 16 by manually rotating the external thread adjusting ring 19, thereby changing the distance between the axis of the grinding wheel 3 and the inner wall of the pipe body 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

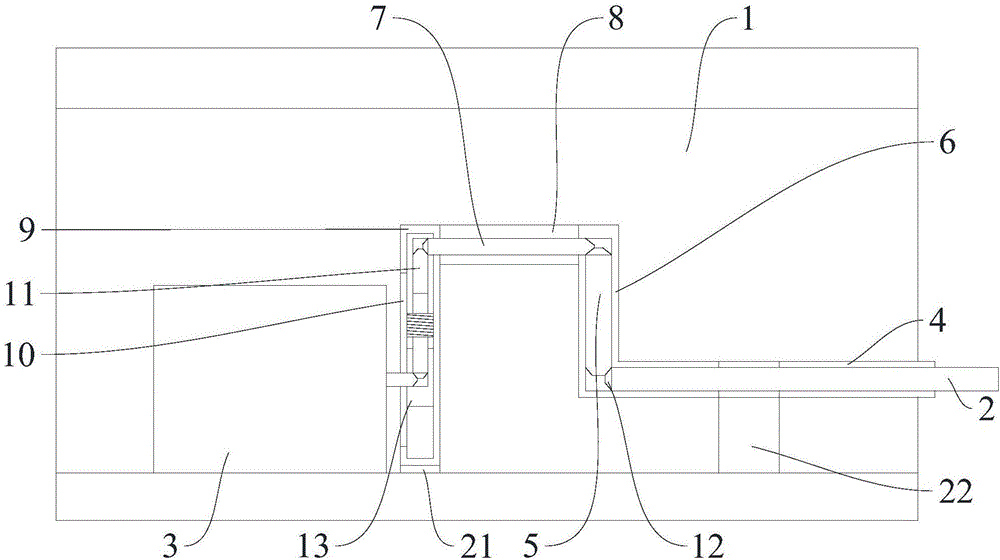

The invention relates to the technical field of metal pipe machining equipment, in particular to a supporting mechanism for steel pipe internal grinding. The supporting mechanism comprises a pipe body, a main driving shaft and a grinding wheel; the main driving shaft is axially and fixedly connected with a rotating shaft of a high-speed motor; the grinding wheel is located in the pipe body; the pipe body is internally provided with a first transverse driving pipe; and the main driving shaft is inserted into the first transverse driving pipe and is movably connected with the internal wall of the first transverse driving pipe. According to the supporting mechanism for the steel pipe internal grinding, the high-speed motor is connected with the grinding wheel by driving shafts in driving pipes which communicate mutually, and the height of the connecting end of the grinding wheel is changed freely by employing a second longitudinal driving shaft formed by an upper rotating shaft and a lower rotating shaft, so that the mounting height of the grinding wheel can be adjusted, the application scope of the diameter of the grinding wheel is widened substantially, and the service life of the single grinding wheel is prolonged substantially.

Description

technical field [0001] The invention relates to the technical field of metal pipe processing equipment, in particular to a support mechanism for internal rounding of steel pipes. Background technique [0002] In the internal grinding equipment for metal pipe workpieces, the existing technology is to connect the motor and the grinding wheel through the long transmission shaft, and the motor drives the long transmission shaft to rotate to realize the rotation of the grinding wheel, and to grind the inner wall of the metal pipe workpiece. , in order to achieve a better grinding effect, the speed of the motor is usually higher, that is, the working state of the long drive shaft and the grinding wheel is high-speed rotation during the grinding process, and the long drive shaft rotates at high speed, and the long drive shaft and the support bushing The bearings between them are very vulnerable to damage, and the entire support mechanism needs to be replaced, which is expensive and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B5/40B24B5/35B24B47/12

CPCB24B5/40B24B5/35B24B47/12

Inventor 徐华新

Owner HUANGSHI CHENGDA PRECISION MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com