Building robot for brick mortar coating

A construction robot and brick technology, applied in the fields of construction machinery and building decoration, can solve the problems of limited coating thickness and coating area, uneven coating of brick mortar, single application object, etc. Application scenarios, widely used effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

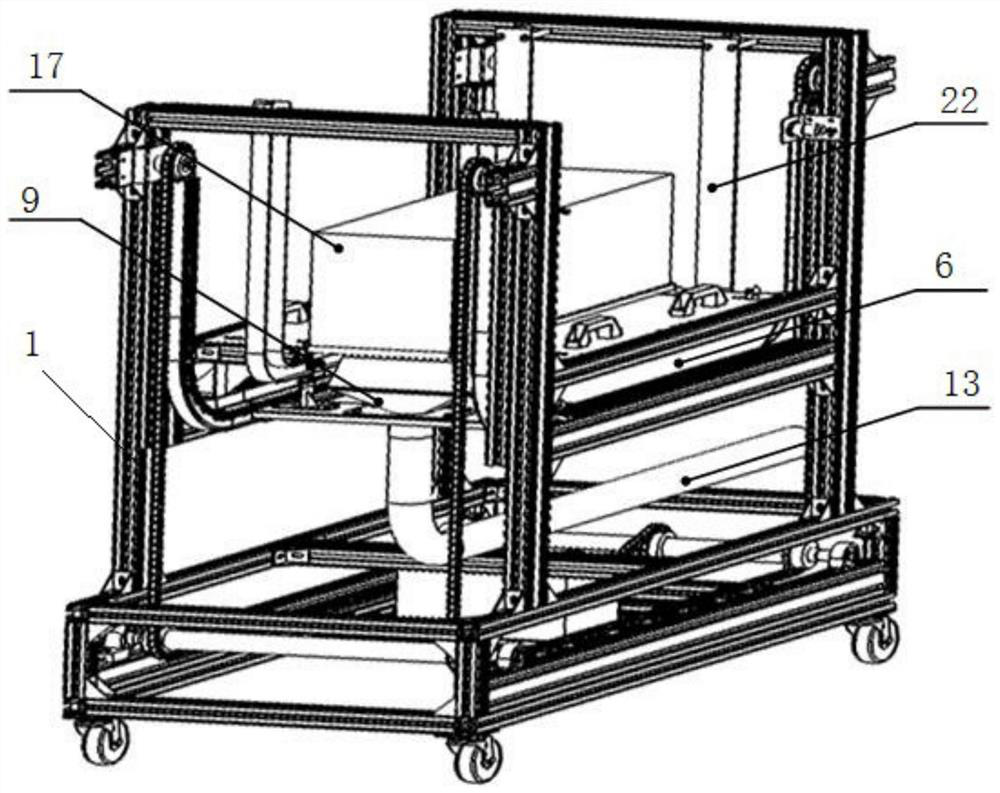

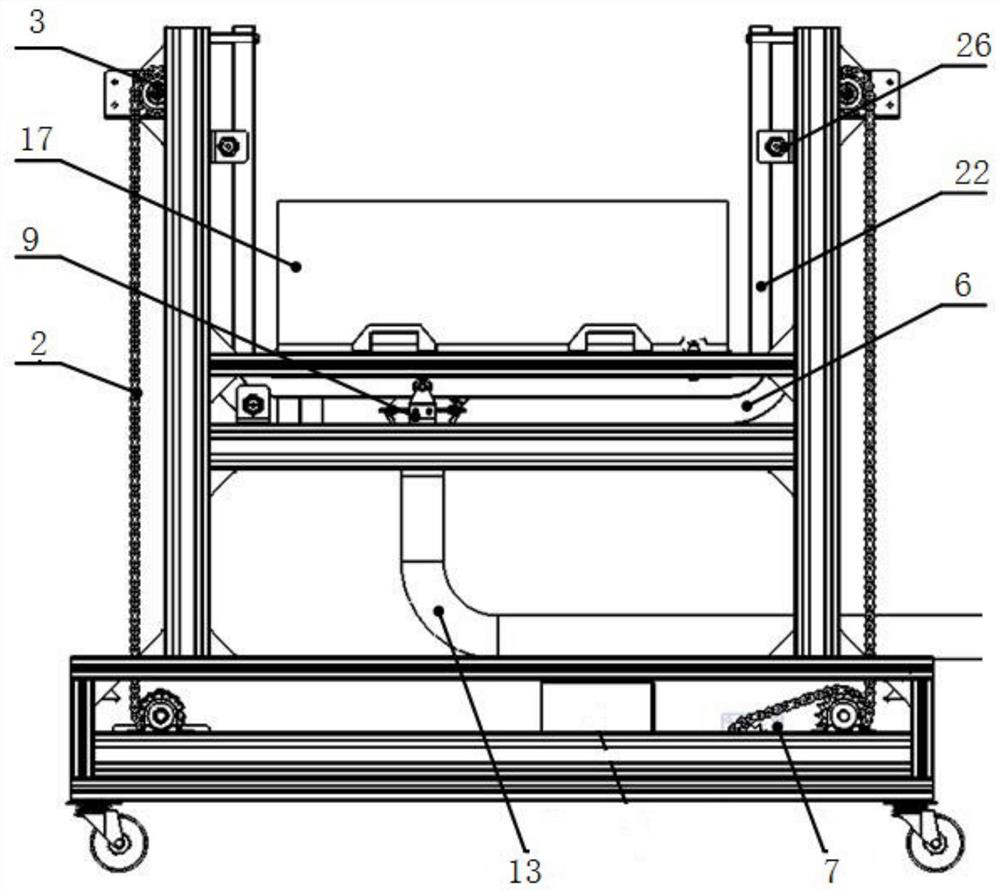

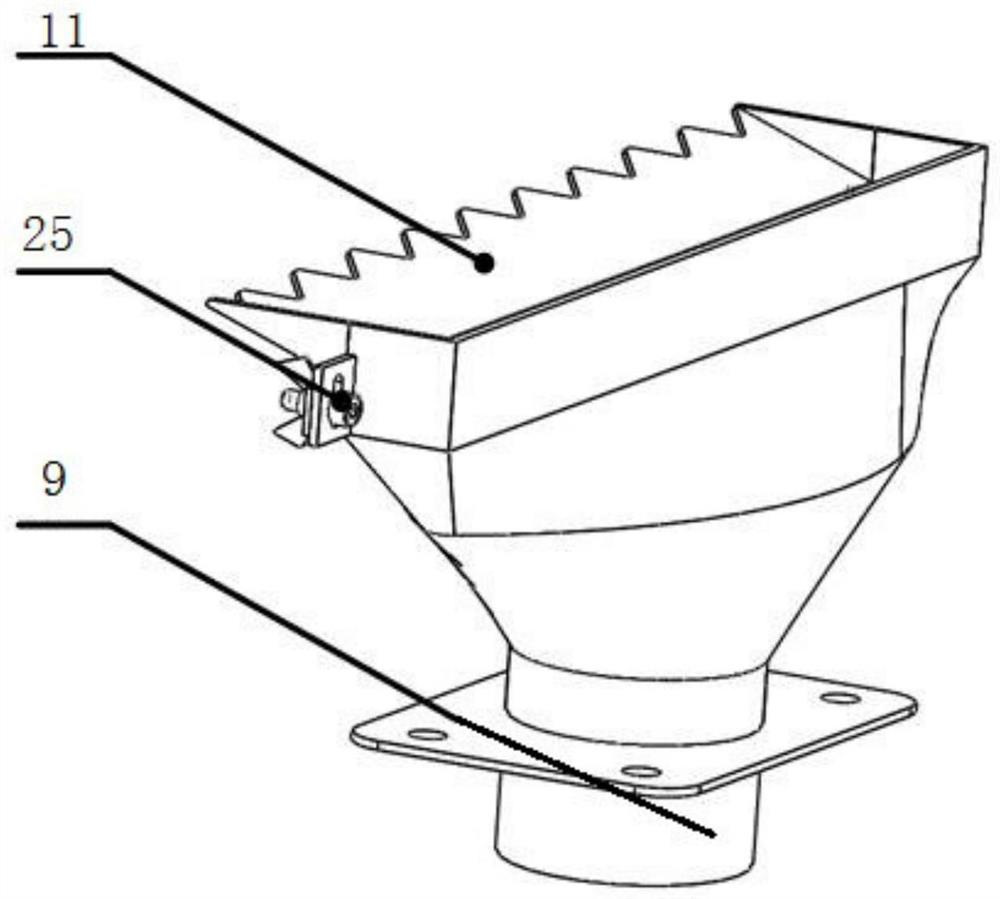

[0023] according to Figure 1-Figure 6 As shown, this embodiment provides a construction robot for brick mortar coating, including a frame 1, a sprocket 3 driving a chain 2 is arranged around the frame 1, two A transmission shaft 4 is connected to the first sprocket 3, and a chain track 6 for installing the conveying pallet 5 is provided in the middle of the frame 1, and the chain 2 around the frame 1 passes through the chain track 6 for circular transmission. One of the transmission shafts 4 is connected with a motor 7, which drives the transmission shaft 4 to rotate, and then drives the chain 2 to move on the sprocket 3 and the chain track 6; the two ends of the conveying pallet 5 are directly connected by the chain side The head 8 is connected to the chain 2 in the chain track, and the middle part of the conveying pallet 5 is fixedly connected with a shower head 9 by bolts. The outer side of the shower head 9 is provided with a protective cover 10, and at the upper end A s...

Embodiment 2

[0034] The working process of a construction robot for brick mortar coating is as follows:

[0035]Step 1: The robot gripper smoothly places the bricks on the positioning plate 16 on the supporting sub-plate of the coating machine. After a delay of 1 second, the photoelectric switch is turned on, and the mortar pumping machine 12 and the coating machine start to work;

[0036] Step 2: The conveying pallet 5 pulls the nozzle 9 to move from one side of the bottom surface of the brick to the other side, and the mortar coating on the bottom surface of the brick is completed so far;

[0037] Step 3: During the turning stage, the mortar pumping machine 12 temporarily stops working, and the delay is about 1 second. When the nozzle 10 quickly turns around the right-angled bend and is completely attached to the side of the brick, the mortar pumping machine 12 continues to work;

[0038] Step 4: When the nozzle 9 moves to the upper edge of the side of the brick, the photoelectric switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com