Jaw wrench

A clamp-type wrench technology, applied in the field of hardware wrenches, can solve the problems of various sizes of wrenches, waste of resources, inconvenient storage and management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

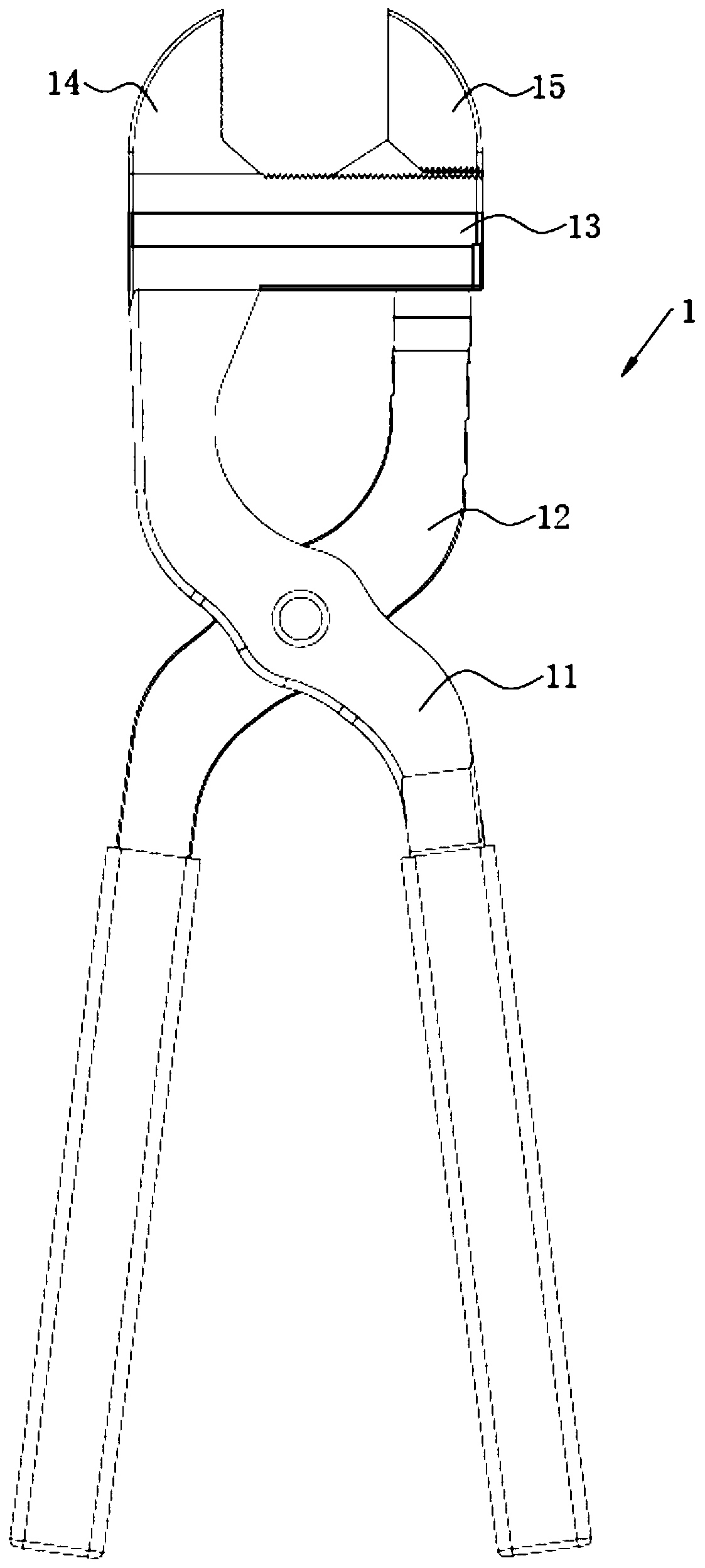

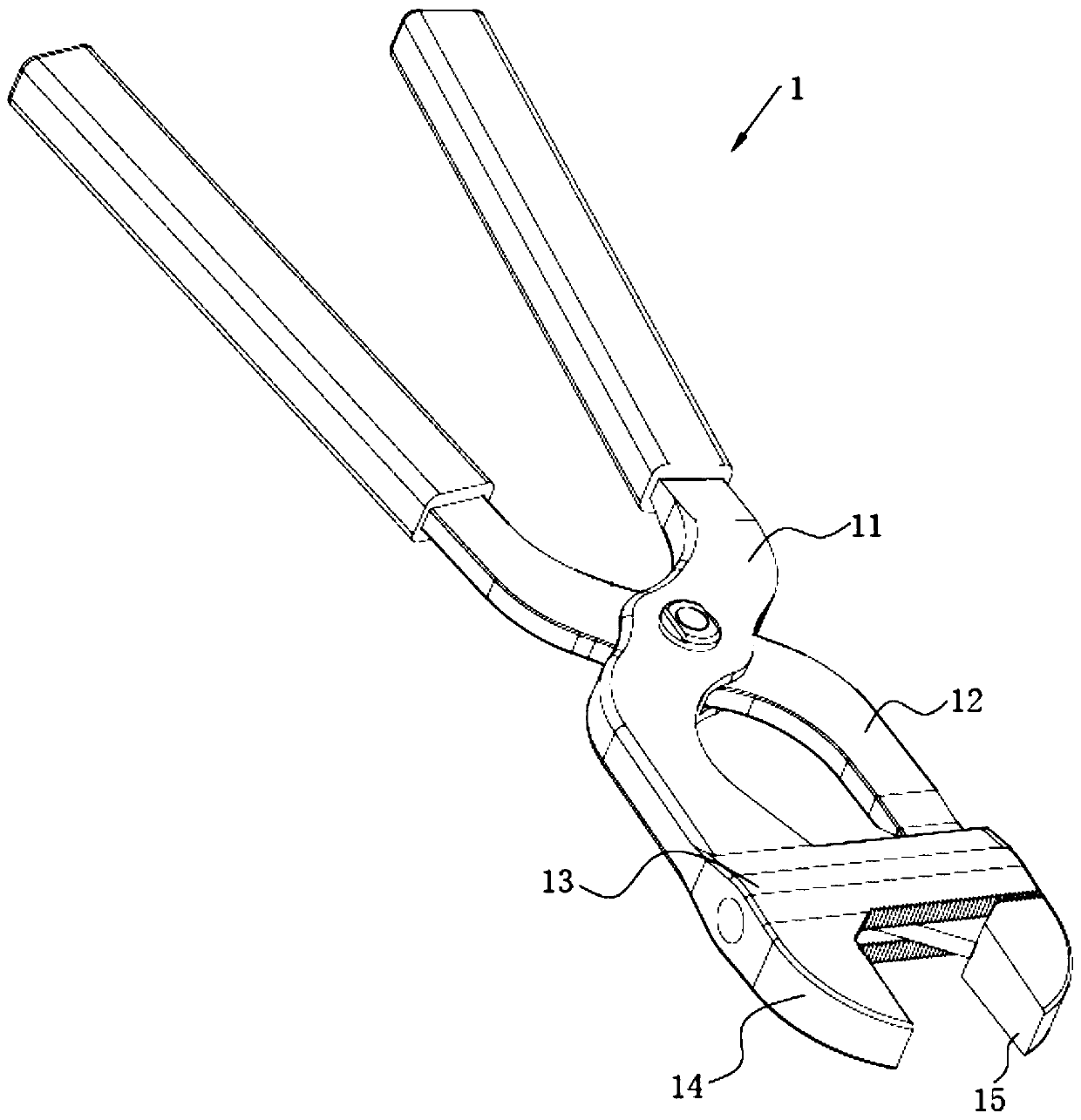

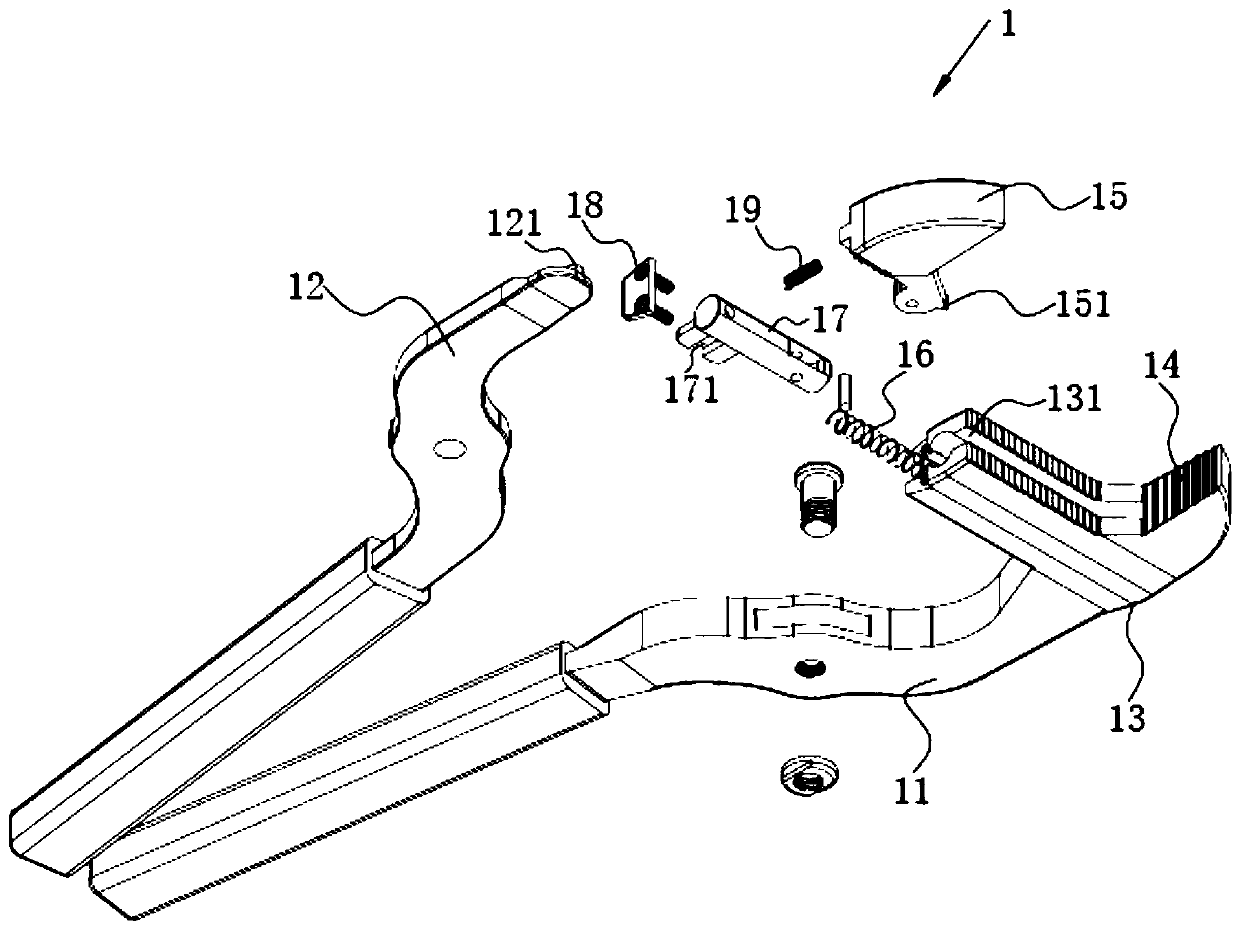

[0050]The pincer wrench 1 includes a cross-hinged primary handle 11 and an auxiliary handle 12 , and also includes a wrench body 13 , a fixed clamping portion 14 , a movable clamping portion 15 and an elastic member 16 . The wrench body 13 is fixed on the end of the main tong handle 11 , and the fixed clamping portion 14 is fixed on the wrench body 13 . A chute 131 is provided in the wrench body 13 , and the end of the auxiliary pliers handle 12 is rotatably connected with the movable clamping part 15 and drives the movable clamping part 15 to slide in the chute 131 . The wrench body 13 is provided with an elastic member installation groove 132 parallel to the direction of the slide groove 131 , the elastic member 16 is disposed in the elastic member installation groove 132 , and the elastic member 16 abuts against the movable clamping portion 15 .

[0051] As mentioned above, the main body of the pliers wrench 1 is in the shape of pliers, and the main pliers handle 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com