Universal locating clamp

A positioning fixture, a universal technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as difficult to popularize and use, long operating hours, long alignment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

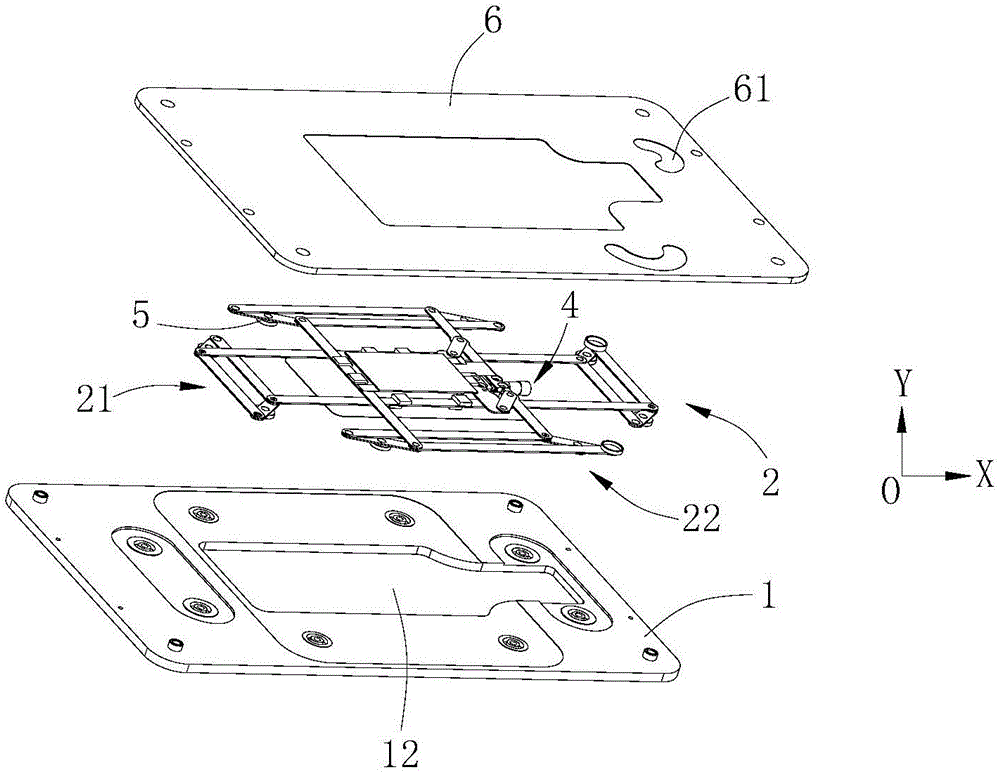

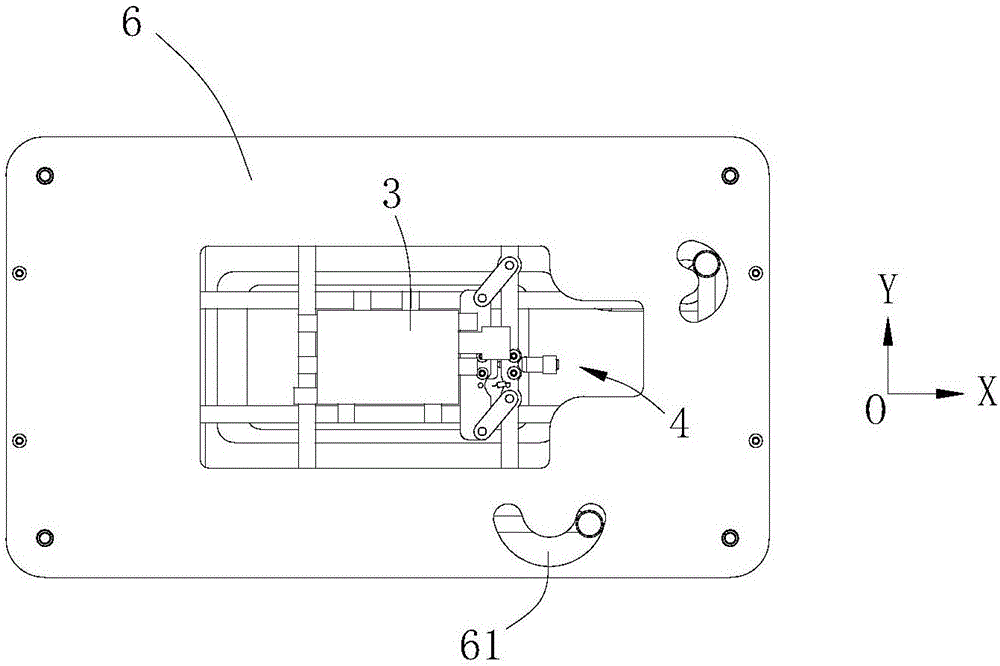

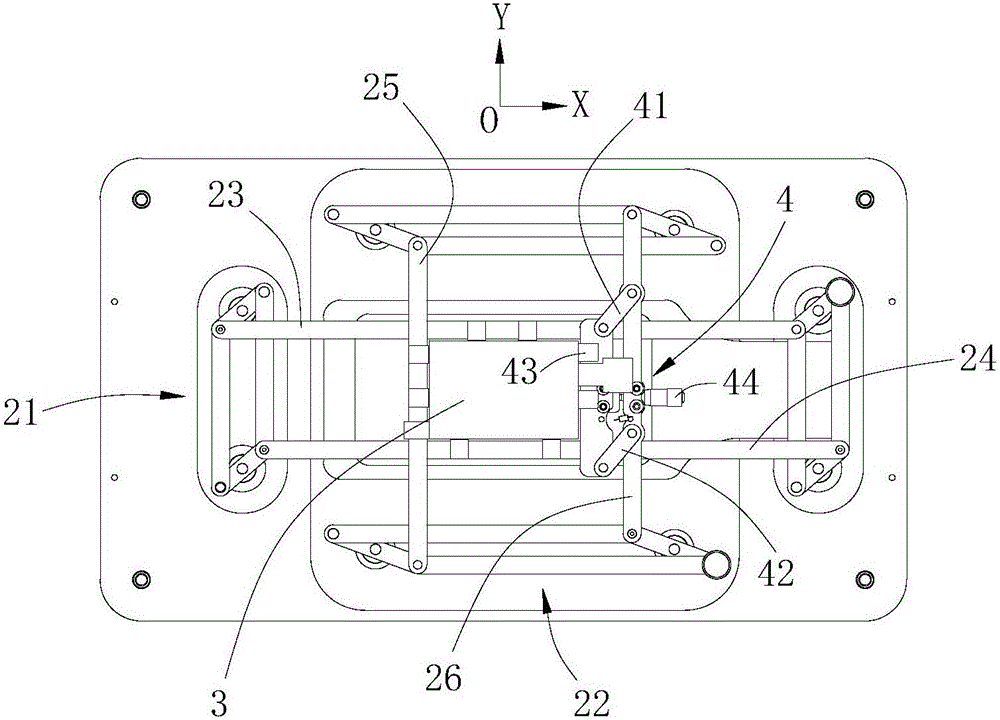

[0025] Such as Figure 1 to Figure 5 As shown, a universal positioning fixture in this embodiment includes a fixture seat 1 and a link positioning mechanism 2 pivotally connected to the fixture seat 1. The link positioning mechanism 2 includes a Y that is symmetrically arranged on the fixture seat 1. Two first parallelogram linkages 21 on both sides of the axis, two second parallelogram linkages 22 symmetrically arranged on both sides of the X-axis of the fixture seat 1, and two first parallelogram linkages 22 arranged laterally on the two sides of the first parallelogram Between the link mechanisms 21 and longitudinally arranged between two second parallelogram link mechanisms 22, several positioning links for forming the workpiece positioning frame;

[0026] Specifically, the plurality of positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com