Integrally-molded shoe sole and manufacturing mold and production method thereof

A production method and integrated technology, applied in the field of shoe manufacturing, can solve the problems of not being able to take into account wear resistance and elasticity at the same time, the spring cannot be seen, and the midsole is not wear-resistant, etc., and achieves good shock absorption effect, long service life, and softness. elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

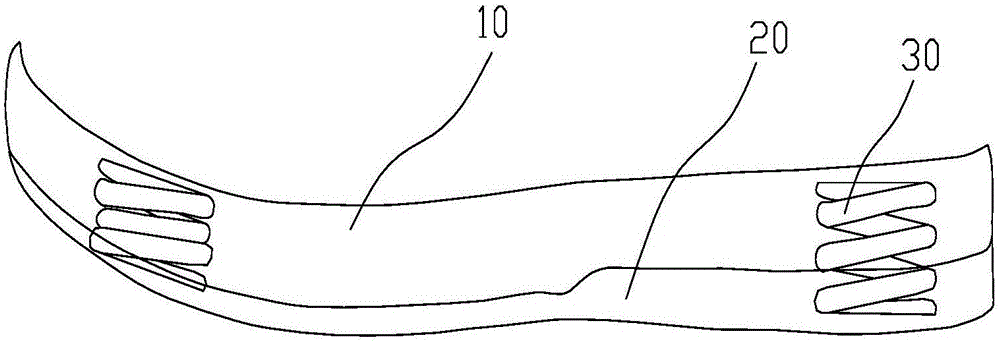

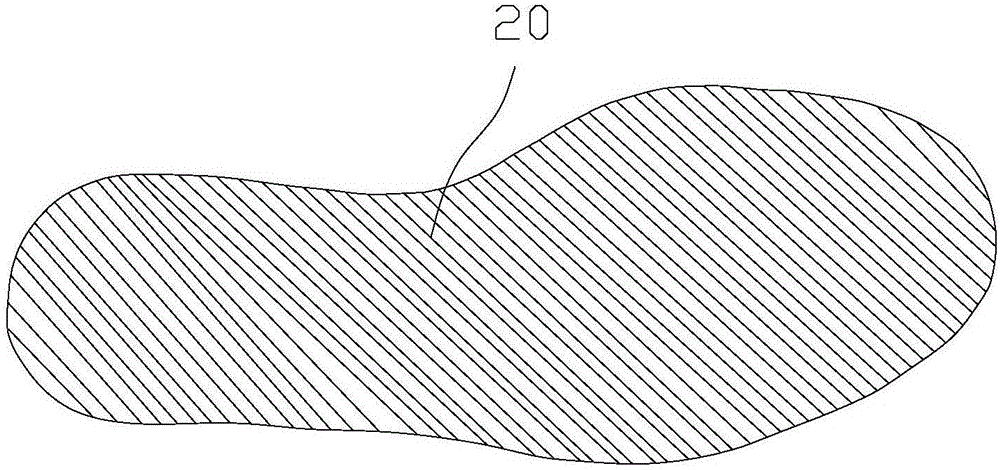

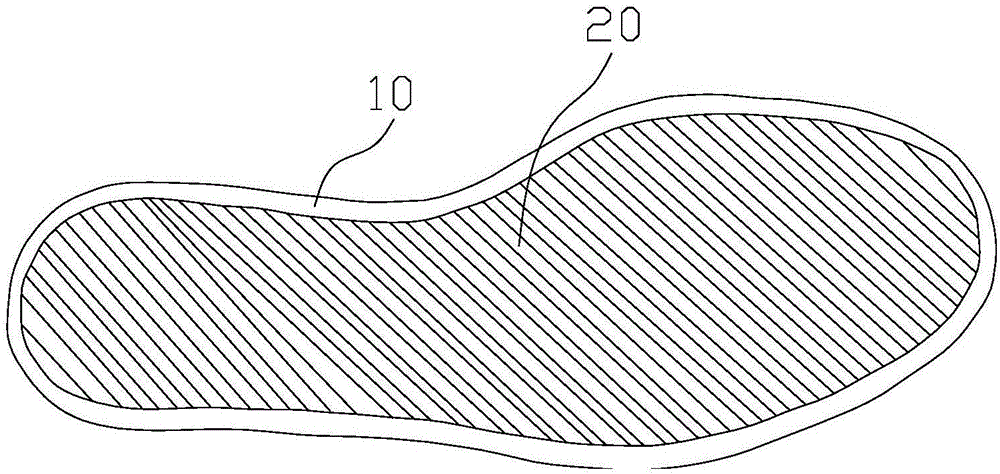

[0048] Such as Figure 1-2 As shown, the embodiment of the present invention provides a kind of one-piece molded sole, comprises the midsole 10 of foam molding and the outsole 20 of non-foaming molding; One-time foaming and integral molding in the same mold.

[0049] More specifically, the midsole 10 is made of PU foam material; the outsole 20 is made of PU non-foam material. PU non-foaming material is a liquid material with physical properties close to that of rubber. It can be purchased from BASF (China) Co., Ltd., the model is POLY.ISO. The PU material is degradable and environmentally friendly. Simultaneously, outsole 20 and midsole 10 all can be set to transparent, and perhaps, outsole 20 and midsole 10 can be formed by the same or different material of color, make sole bring color, increase attractive in appearance; Especially, if The color of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com