Spherical material supplying mechanism

A feeding mechanism and material technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of difficult operation, difficulty, easy generation of powder particles, etc., and achieve stable operation performance and save the number of operators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

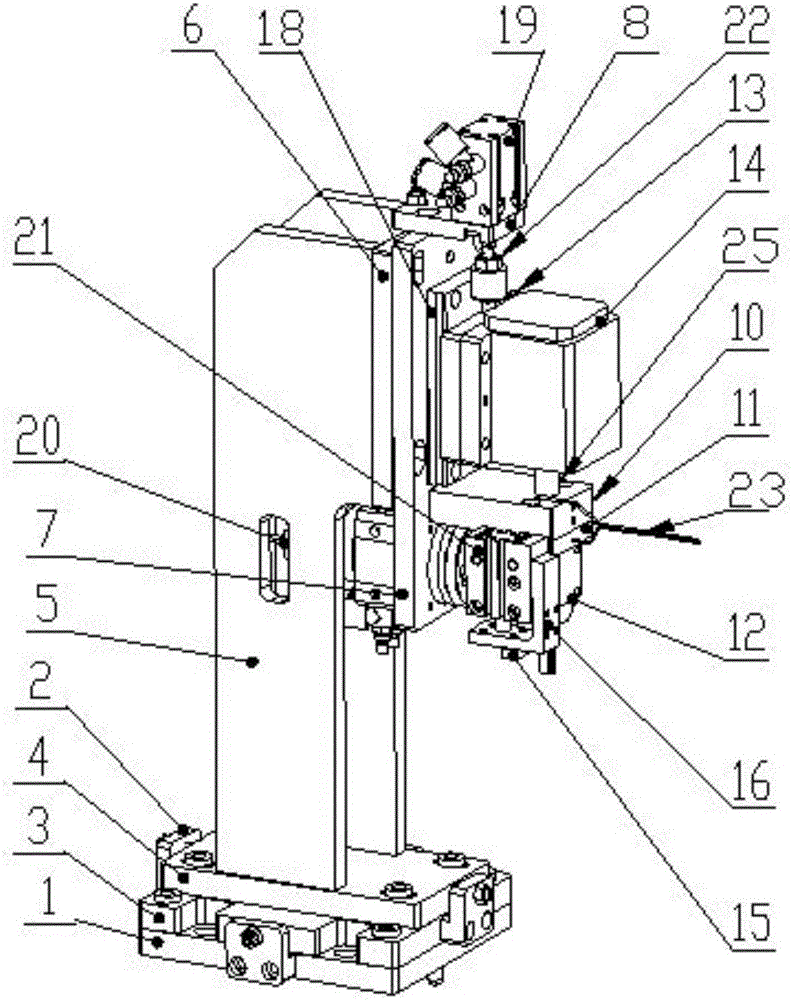

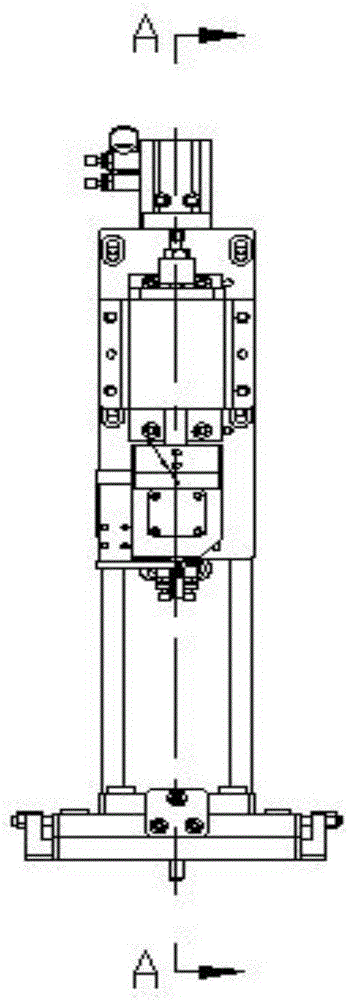

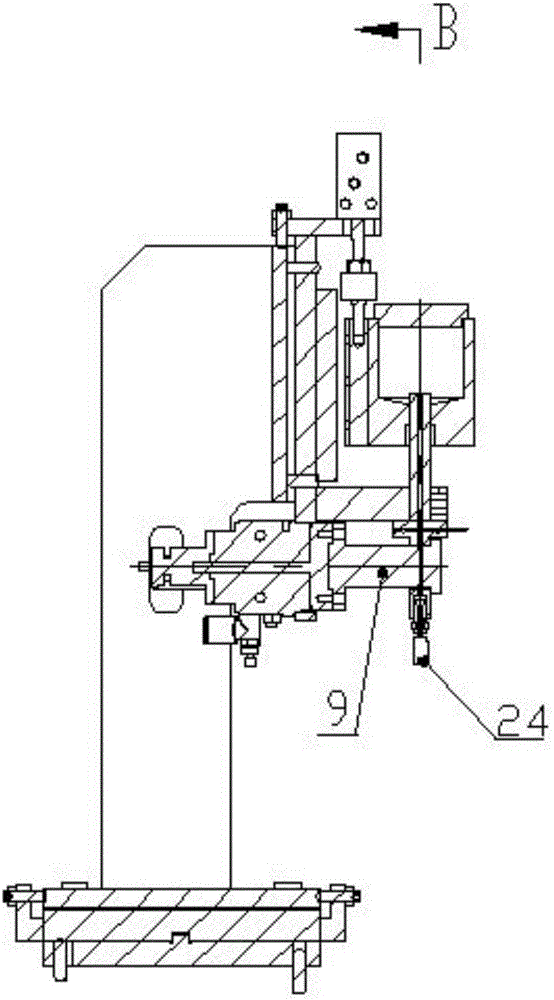

[0020] A spherical material feeding mechanism, comprising: mounting vertical plate 5, height adjustment plate 6, rotary cylinder mounting plate 7, cylinder mounting plate 8, material distribution shaft 9, guide shaft fixing plate 10, ball guide block 11, ball stopper Plate 12, slider mounting plate 13, ball bin 14, cylinder driving plate 15, blanking rod 16, cylinder Ⅰ19, swing table 20, cylinder Ⅱ21, floating joint 22, guide column additional processing inclined surface 25, linear guide rail 18; height The adjustment plate 6 is fixed on the side of the installation vertical plate 5, the rotary cylinder mounting plate 7 is located on the height adjustment plate 6, and there is an adjustment in the Z-axis direction, the cylinder mounting plate 8 is fixed on the rotary cylinder mounting plate 7, and the cylinder I19 is set on the cylinder On the mounting plate 8; the linear guide rail 18 is located on the rotary cylinder mounting plate 7, the slider mounting plate 13 is set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com