Device for truck loading of steel structure material

A steel structure and equipment technology, applied in the direction of lifting device, loading/unloading, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, and many manpower, etc., achieve low labor intensity, improve work efficiency, and increase the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

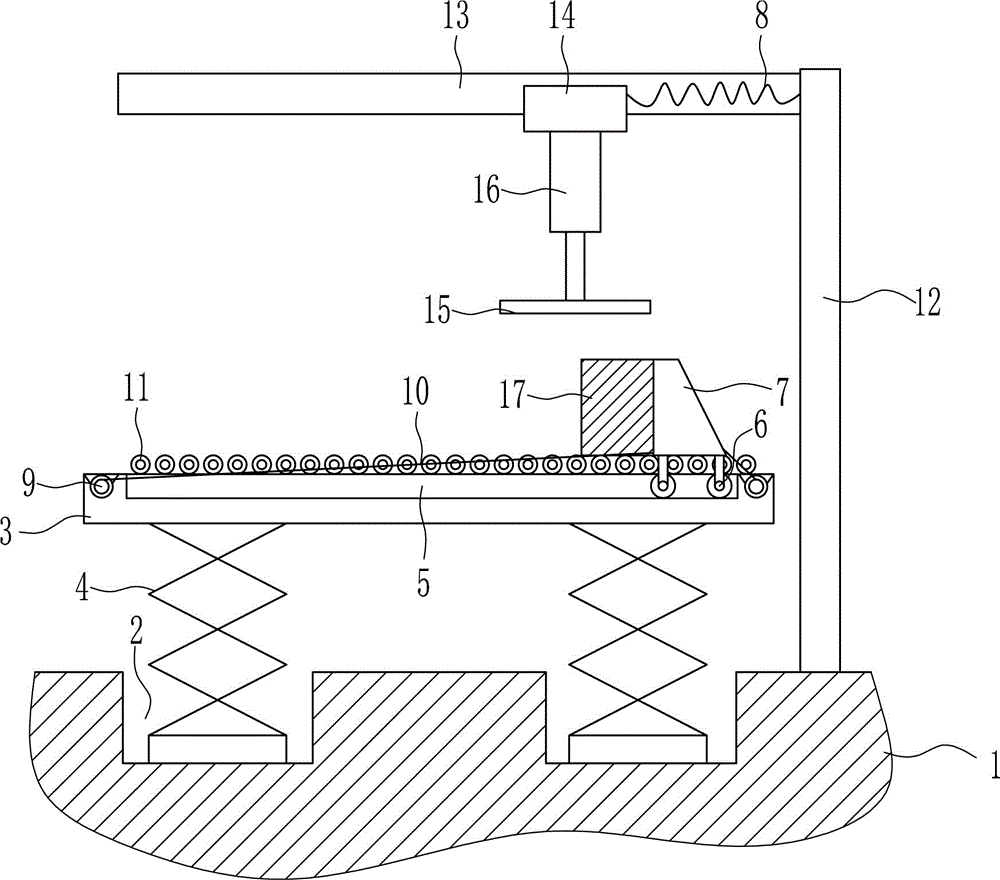

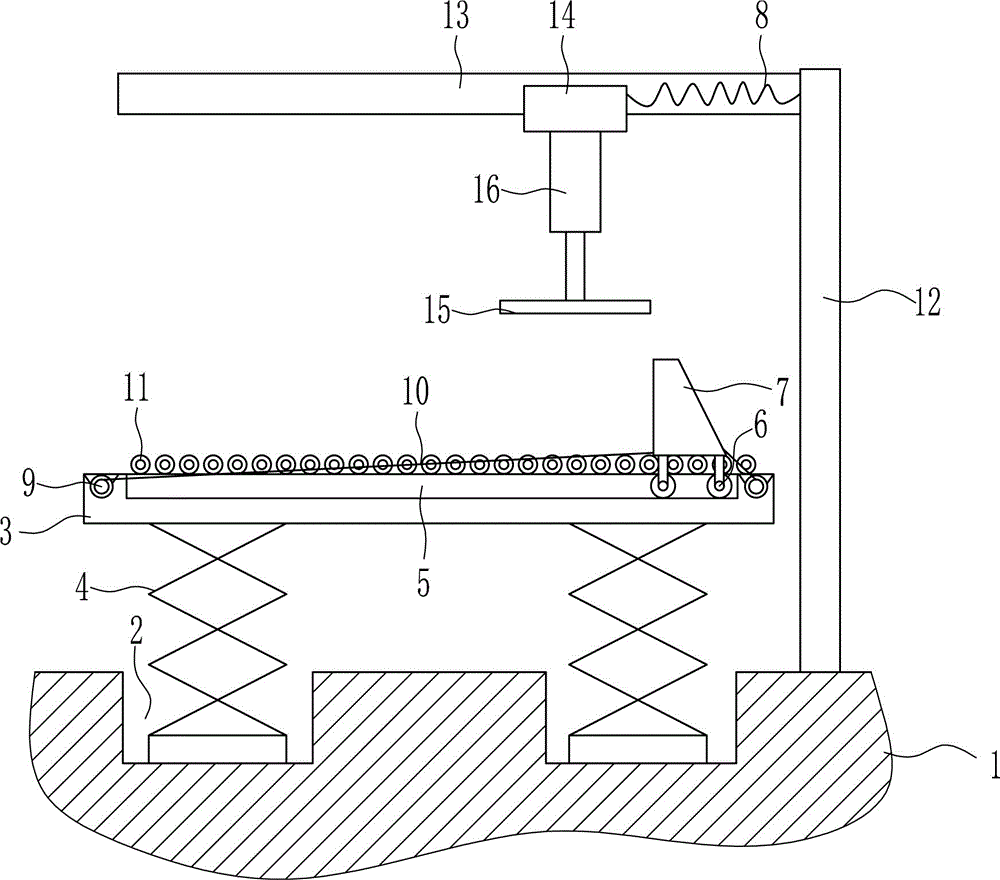

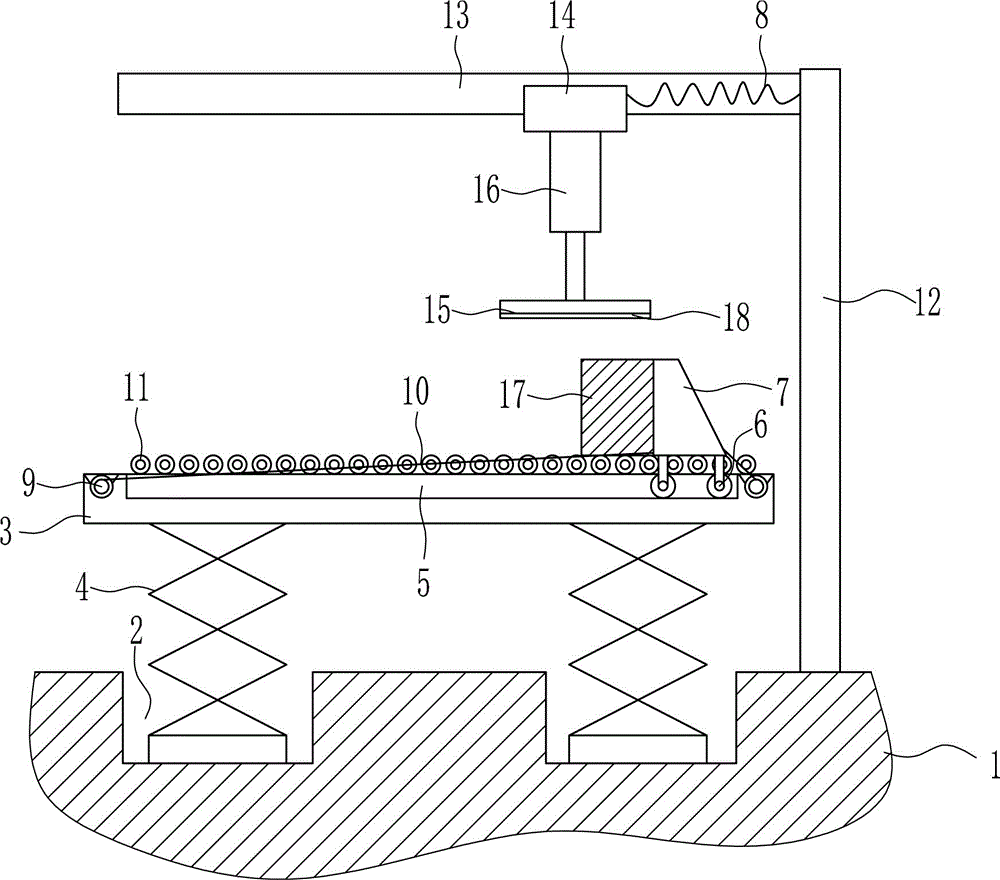

[0027] A kind of equipment for loading steel structure materials, such as Figure 1-3 As shown, it includes a bottom plate 3, a simple elevator 4, a pulley 6, a trapezoidal block 7, a first spring 8, a winch 9, a pull wire 10, a roller 11, a bracket 12, a slide rail 13, a slider 14, a pressure plate 15 and a hydraulic pressure Cylinder 16, the bottom plate 3 is horizontally set, the bottom of the bottom plate 3 is symmetrically connected with a simple elevator 4 through bolt connection, the inner top of the bottom plate 3 is provided with a chute 5, and the sliding type in the chute 5 is provided with a pulley 6, a pulley 6 Slidingly matched with the chute 5, the top of the pulley 6 is welded with a trapezoidal block 7, and the inner top of the bottom plate 3 on the left side of the chute 5 is connected with a winch 9 through bolt connection, and a backguy 10 is wound on the hoist 9, and the end of the backguy 10 is connected to the trapezoidal The blocks 7 are connected by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com