Circulating reciprocate lifting mechanism

A reciprocating and troughing technology, applied in the direction of hoisting device, hoisting device, etc., can solve the problems of high equipment cost, low transportation efficiency, large loss of power and energy consumption, etc., and achieve high space utilization, improve transportation efficiency, transportation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

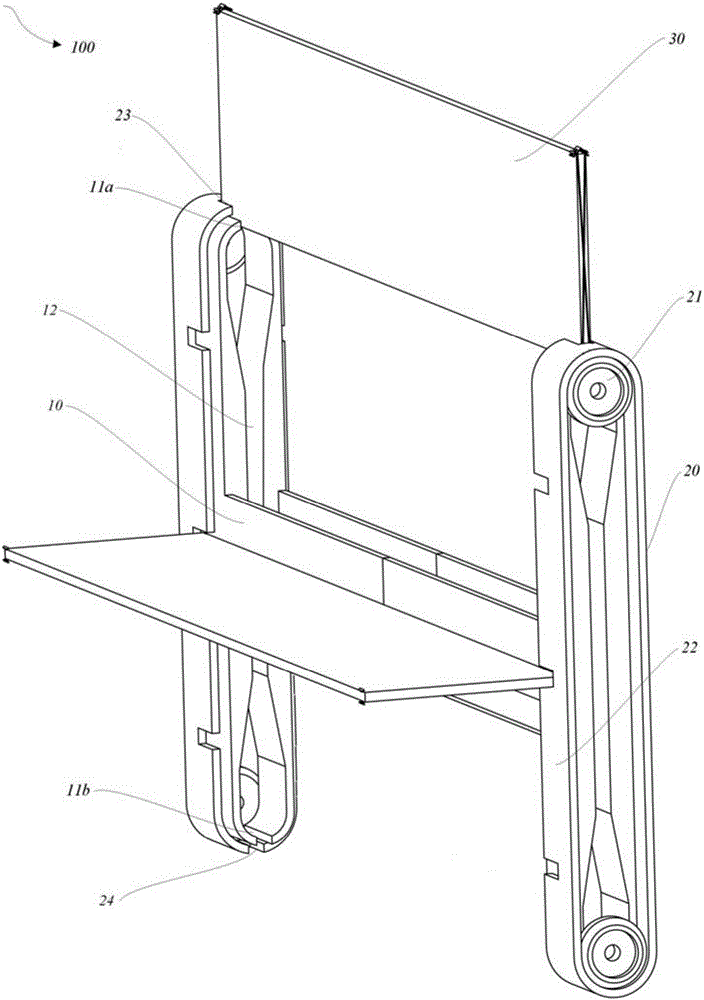

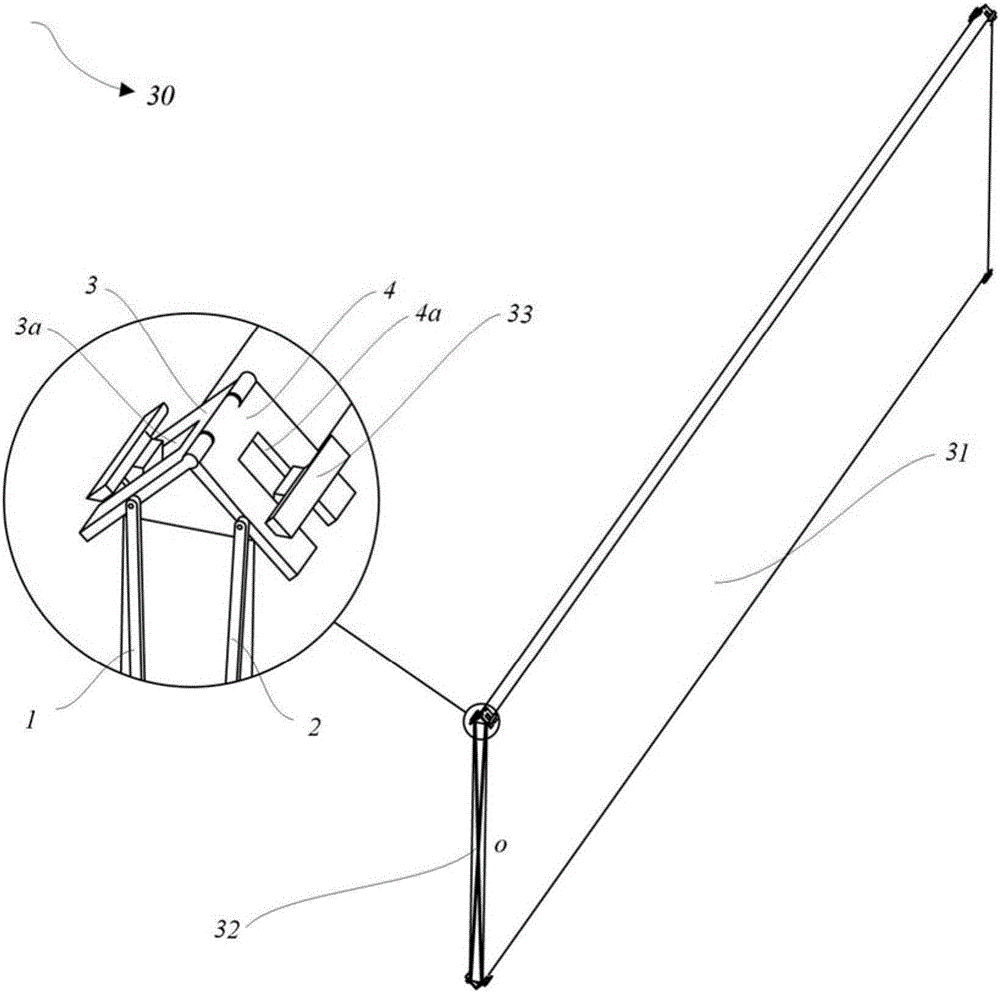

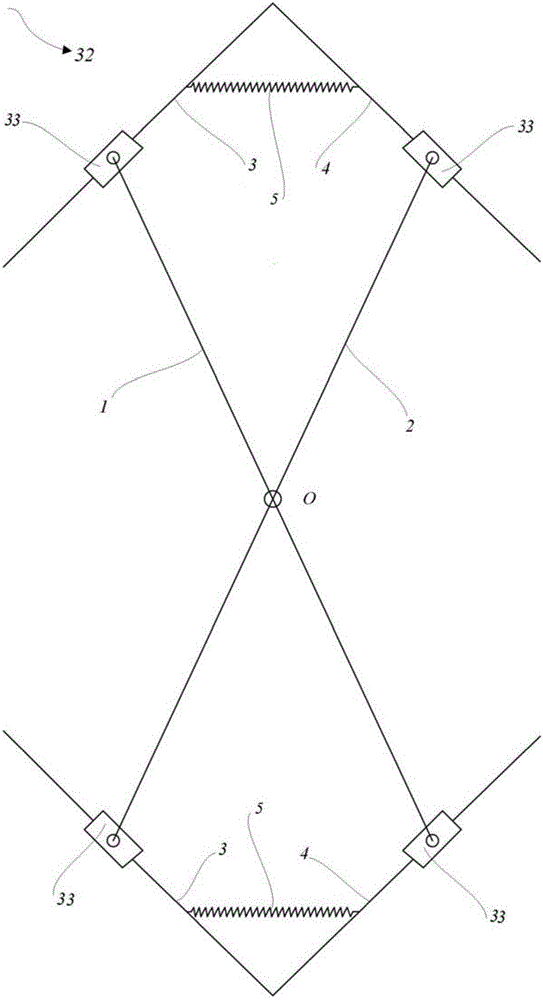

[0023] figure 1 It is a structural schematic diagram of a reciprocating lifting mechanism according to an embodiment of the present invention. As shown in the figure, the reciprocating lifting mechanism 100 includes: a support frame 10 , a pair of conveying devices 20 and a loading board 30 .

[0024] The support frame 10 has a vertical slot 12, and the two ends of the slot 12 include an inlet and an outlet. The supporting frame 10 can be fixed on the ground or any movable equipment.

[0025] A pair of conveying devices 20 are arranged around two sides of the outer contour of the su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap