Oxidizing agent controllable adding device capable of improving quality of graphene in batch preparation

A technology of adding device and graphene, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of excessive oxidation of expanded graphite, poor performance, and inability to uniformize the concentration of oxidants, so as to improve the uniformity and optimize the addition of graphite. Effects of speed and scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

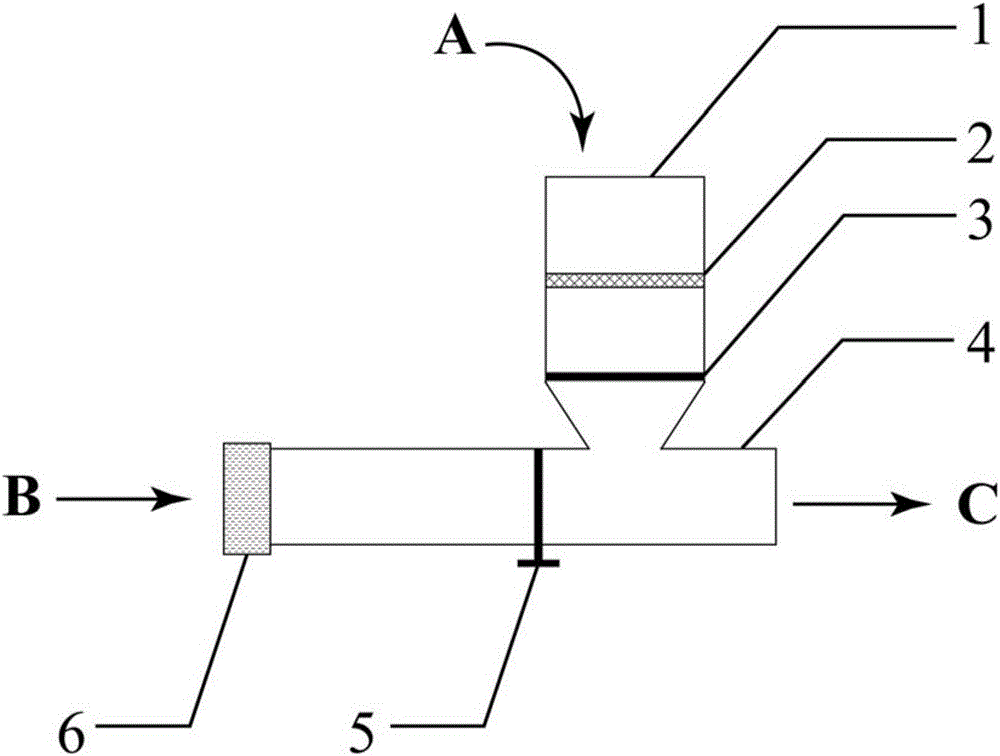

[0013] see figure 1 , the embodiment of the present invention is provided with feed bin 1, air intake and feed pipe 4; The upper opening of described feed bin 1 is provided with feed inlet, and the lower end of feed bin 1 is equipped with screen 2 and valve 3, and valve 3 It is connected with the air intake and feed pipeline 4, one end of the air intake and feed pipeline 4 is connected to the reaction chamber, a safety valve 5 is arranged in the middle of the air intake and feed pipeline 4, and the other end of the air intake and feed pipeline 4 A pipeline interface 6 is provided, and the pipeline interface 6 is externally connected to the air inlet B.

[0014] The diameter of the air inlet and feeding pipeline may be 10-16 mm.

[0015] The air intake and feed pipeline can adopt pulse jet.

[0016] The using method of the present invention is given ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com