Vacuum water quenching system and vacuum water quenching method of bearing

A water quenching and vacuum technology, used in quenching devices, furnaces, heat treatment equipment and other directions, can solve the problems of unstable performance of organic PAG, oil quenching is not hard, water quenching is easy to crack, etc., to achieve safe processing technology, product quality improvement, The effect of reserve reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and examples: the following examples are preferred modes for realizing the present invention, and the following various implementations can be used interchangeably or in part.

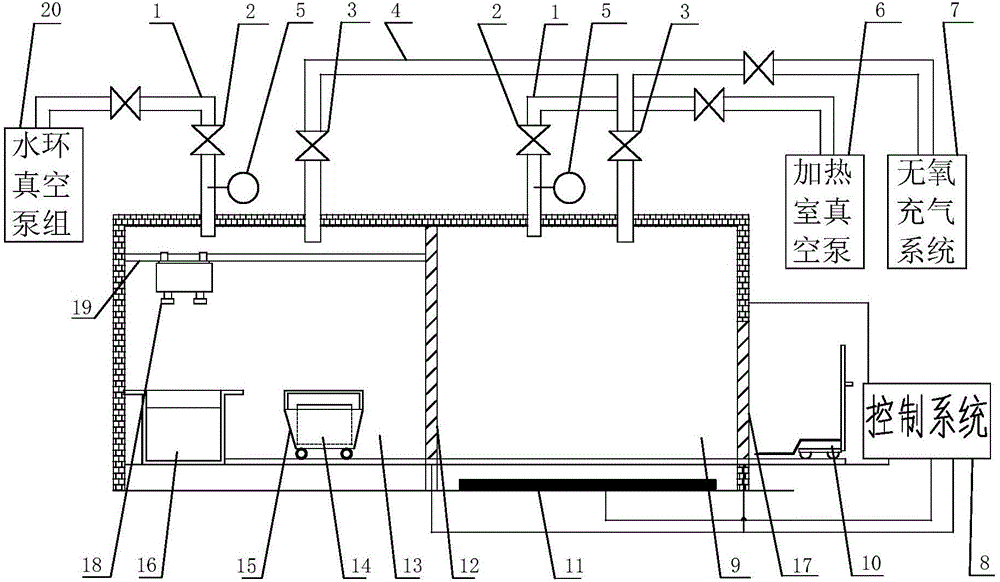

[0032] like figure 1 The vacuum water quenching system shown is provided with a heating chamber 9 and a cooling chamber 13, and the heating chamber 9 and the cooling chamber 13 are separated or communicated with each other by a heat-insulating sealing door 12 of the cooling chamber; the cooling chamber 13 communicates with the outside world through a sealing door 21 of the cooling chamber, Carry out the feeding and taking out of materials; the heating chamber 13 is sealed or communicated with the outside world with the heating chamber inspection door 17, and the heating chamber inspection door 17 is used for inspection and maintenance.

[0033] The heating chamber 9 and the cooling chamber 13 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com