Valve path structure for prior control over movable arm and hydraulic excavator

A technology for priority control valves and hydraulic excavators, which is applied to earth movers/shovels, construction, etc., can solve problems affecting operating efficiency and increasing oil circuit resistance, so as to improve operability, reduce fuel consumption, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

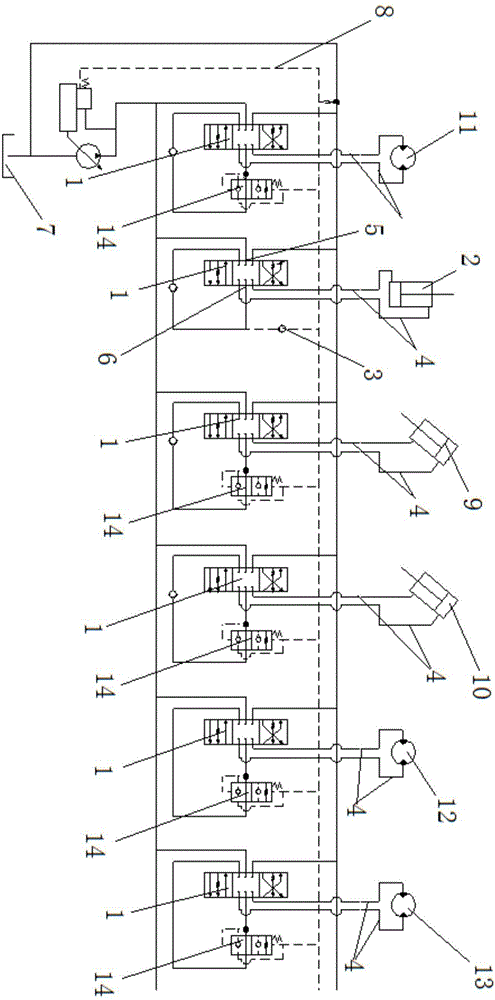

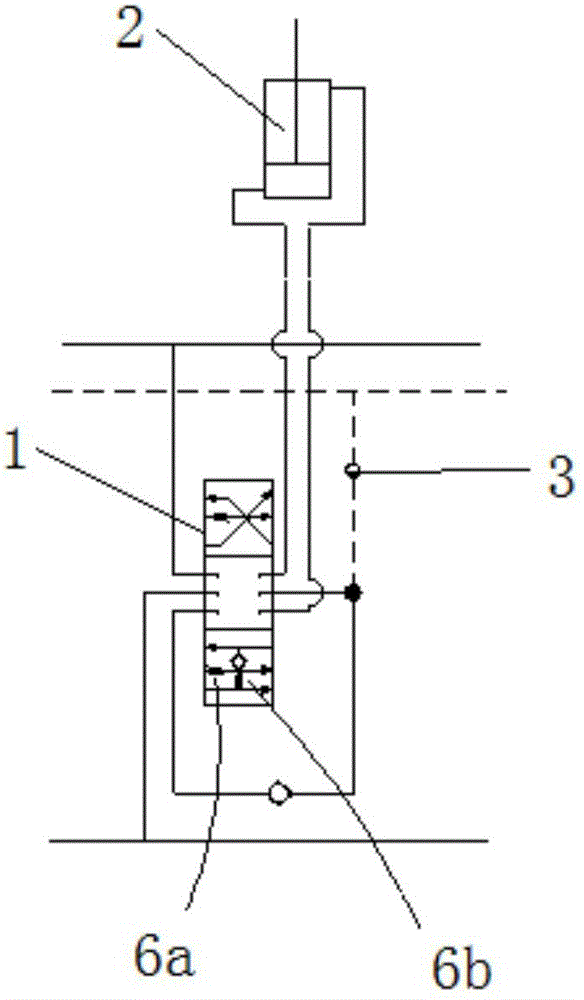

[0028] See Figure 1 to Figure 2 As shown, it shows a preferred embodiment of the boom priority control valve circuit structure, which is suitable for the control oil circuit of hydraulic excavators, including the boom control oil circuit and the common oil circuit 8, the boom control oil circuit Including switching valve 1, boom cylinder 2 and anti-reverse valve 3, switching valve 1 is connected to boom cylinder 2 through two oil pipes 4, the oil inlet 5 of switching valve 1 is connected to fuel tank 7, and the outlet inspection port of switching valve 1 6 is directly connected to the common oil passage 8 through the anti-reverse valve 3.

[0029] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to figure 1 and figure 2 as shown,

[0030] In a further embodiment of the present invention, it also includes a stick control oil circuit, including a stick cylinder 9, a switching valve 1 and a pressure compen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com