Method for cleaning excessive materials in conveying pump pipe by adopting medium favorable for separation of concrete mixture

A mixture and concrete technology, applied in the processing of building materials, building structure, construction, etc., can solve problems such as hidden quality problems of finished structural concrete, affecting on-site civilized construction, quality diseases, etc., to shorten the flushing time, improve the The effect of ergonomics and environmental protection resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

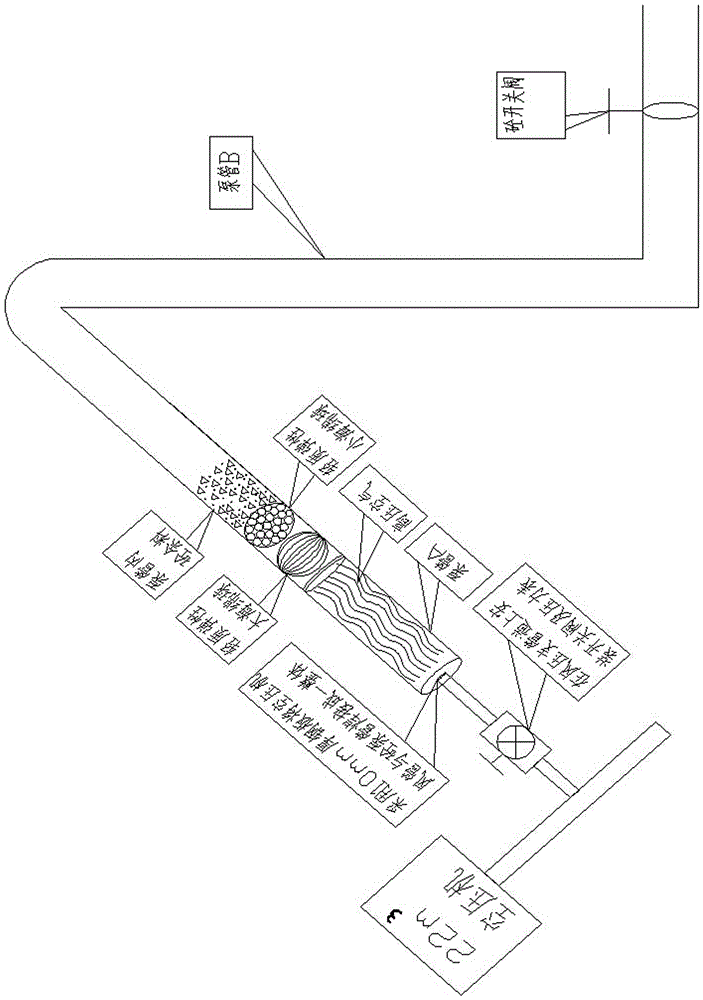

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0018] The invention provides a method for cleaning the remaining material in the delivery pump pipe with a medium that is easy to separate the concrete mixture. The specific implementation steps are as follows:

[0019] 1. Pump pipe transformation

[0020] The pump pipe is processed so that the pump pipe can be connected with the air duct of the air compressor, which is convenient for air pressure cleaning.

[0021] The specific method is as follows: cut 50cm, Φ125 pump tube A with a joint at one end, connect the pump tube A with the joint end to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com