Real-time automatic monitoring system and method for acoustic, electric and gas in coal-rock dynamic disasters

An automatic monitoring and dynamic disaster technology, which is applied in the direction of earth drilling, mining equipment, mining equipment, etc., can solve the problems of low detection and identification accuracy, poor real-time performance, and great impact on safe and efficient production, so as to improve the degree of automation and early warning Accuracy, the effect of ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

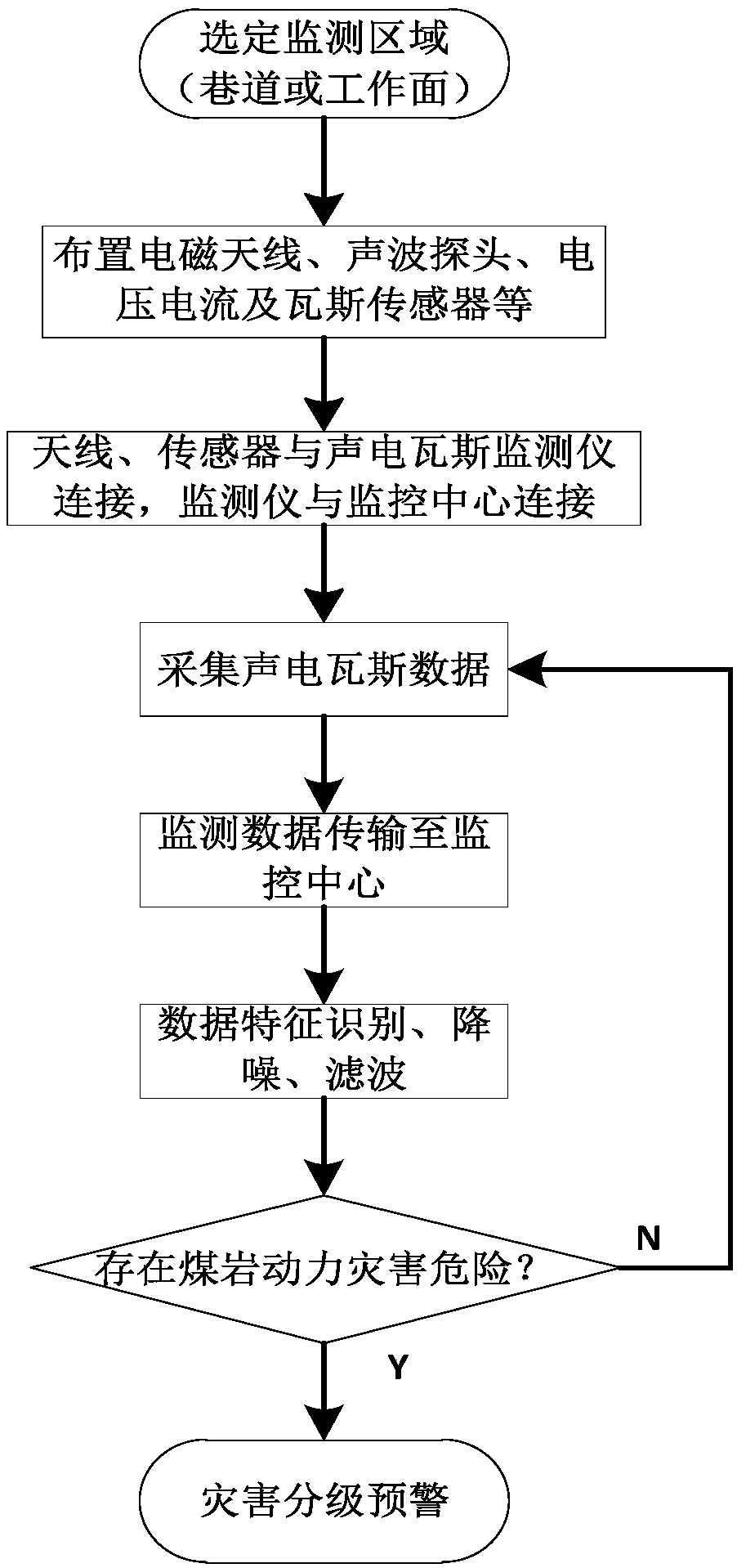

Method used

Image

Examples

Embodiment Construction

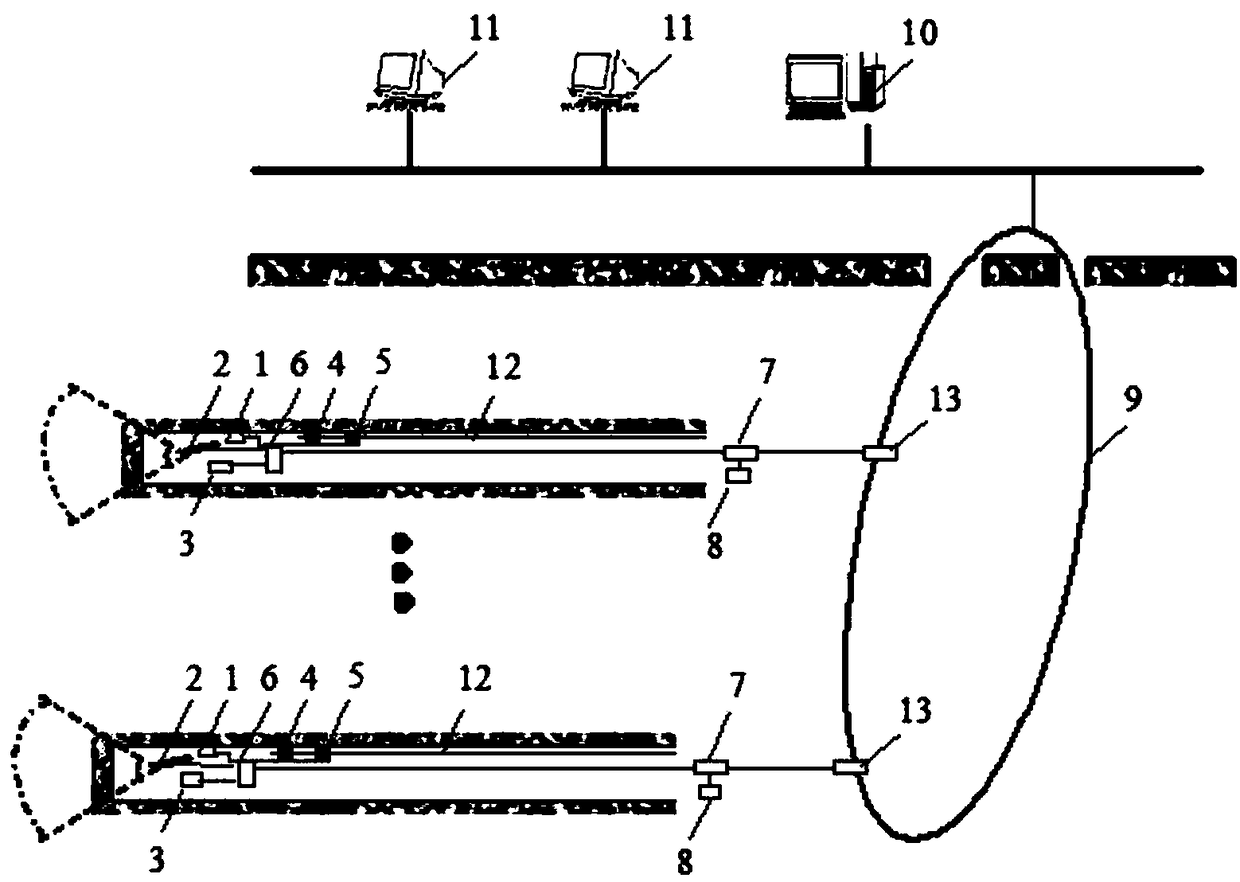

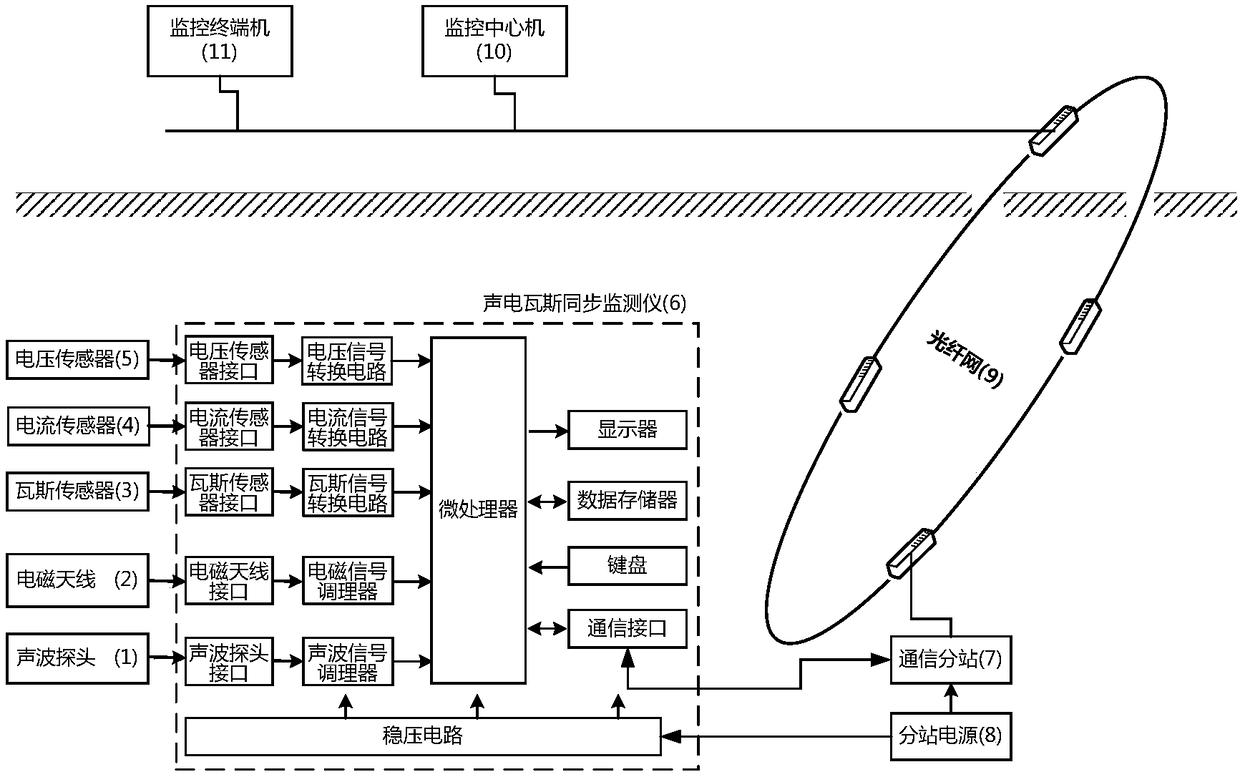

[0021] An example of the present invention will be further described below in conjunction with accompanying drawing:

[0022] Real-time automatic monitoring system of sound, electricity and gas for coal and rock dynamic disasters, including sound wave probe, electromagnetic antenna, gas sensor, current sensor, voltage sensor, sound, electricity and gas synchronous monitor, communication substation, substation power supply, optical fiber network, monitoring center computer, Monitoring terminal machine; acoustic wave probe 1, electromagnetic antenna 2, current sensor 4, voltage sensor 5 and gas sensor 3 are connected to the corresponding sensor input interface of the acoustic-electric gas synchronous monitor 6; the communication interface of the acoustic-electric gas synchronous monitor 6 is connected to the communication The input end of the substation 7 is connected, and the communication substation 7 is connected with the monitoring central machine 10 and the monitoring termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com