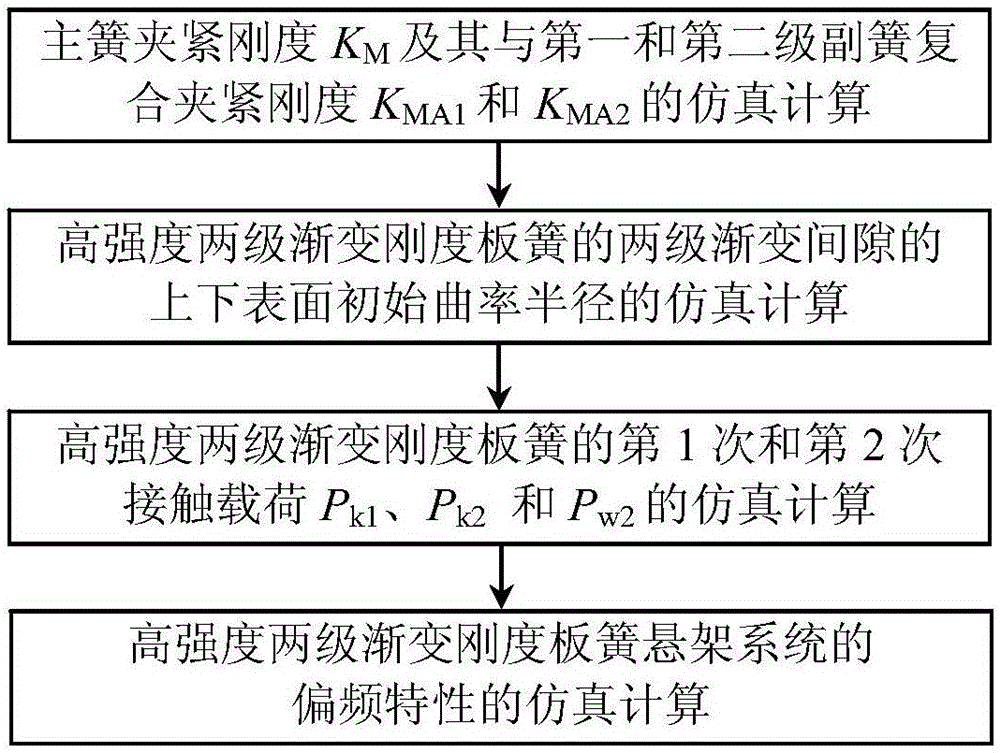

Simulating calculation method for offset frequency characteristic of high-strength two-stage gradual change stiffness leaf spring suspension system

A simulation calculation and leaf spring suspension technology, which is applied in the field of vehicle suspension leaf springs, can solve the calculation of the stiffness characteristics of high-strength two-stage gradient stiffness leaf springs, which is very complex and does not give high-strength two-stage gradient stiffness leaf spring suspensions. System offset characteristics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

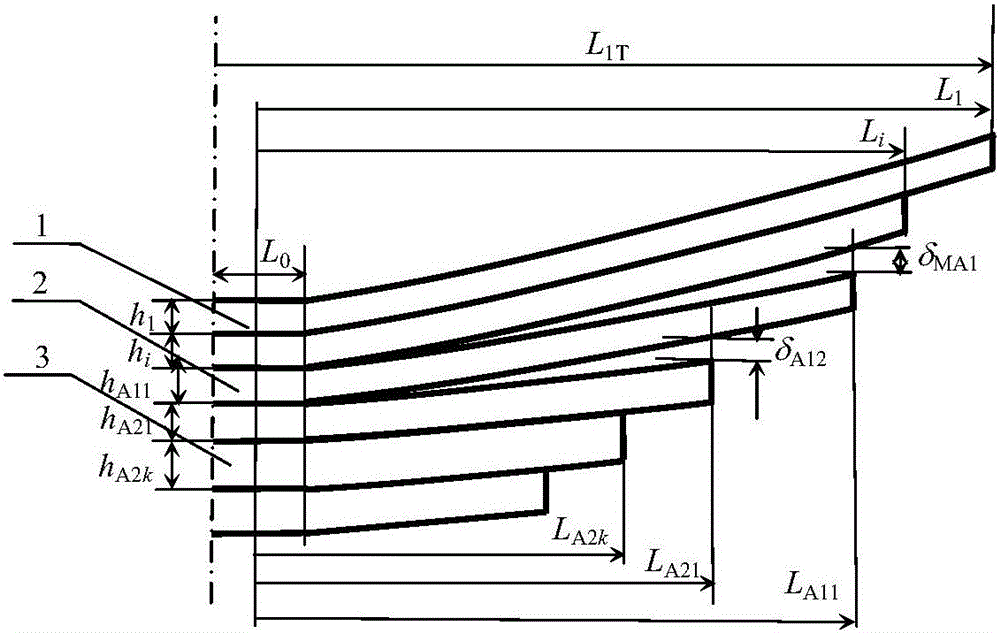

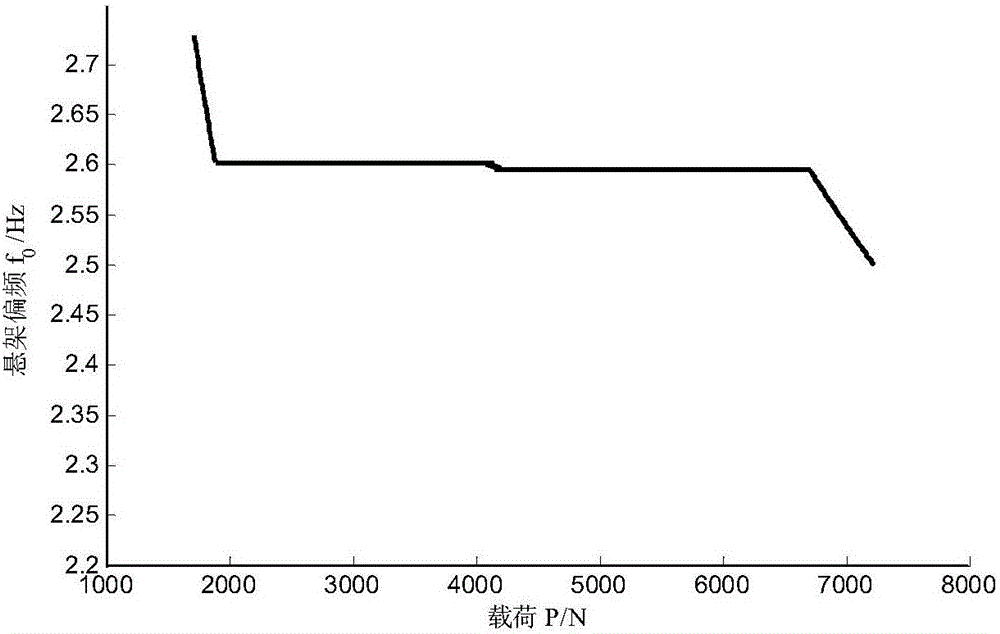

[0054] Example: the width b=63mm of a high-strength two-stage gradient stiffness leaf spring, half of the clamping distance L of the riding bolt 0 =50mm, elastic modulus E=200GPa. The total number of main and auxiliary springs is N=5, among which, the number of main springs is n=2, and the thickness of each main spring is h 1 =h 2 =8mm, the half length of each piece of the main spring is L respectively 1T =525mm, L 2T =450mm; half clamping length is L respectively 1 =L 1T -L 0 / 2=500mm, L 2 =L 2T -L 0 / 2=425mm; the design value H of the initial tangent arc height of the main spring gM0 =112.2mm. The number of pieces of the first-stage auxiliary spring m 1 =1 piece, thickness h A11 =11mm, half length is L A11T =360mm, half clamping length L A11 =L 3 =L A11T -L 0 / 2=335mm; the design value H of the initial tangent arc height of the first-stage auxiliary spring gA10 =22.8mm. The number of pieces of the second-stage auxiliary spring m 2 = 2 pieces, the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com