hydraulic buffer

A technology of hydraulic buffer and buffer cylinder, which is applied in the field of hydraulic buffer, can solve the problems of reduced buffer effect and inability to adjust buffer force, and achieves the effect of maximizing performance and adjustable buffer force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

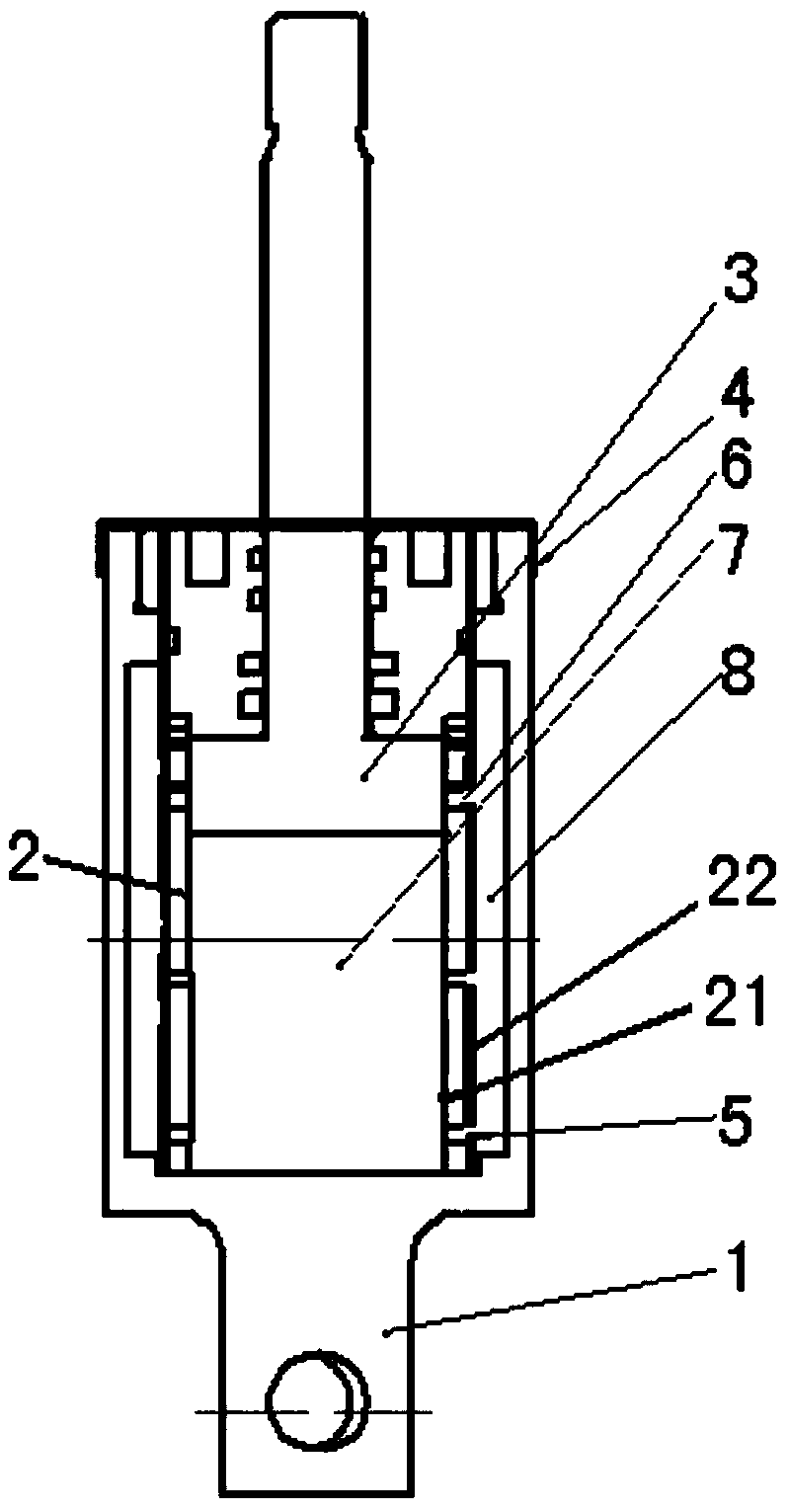

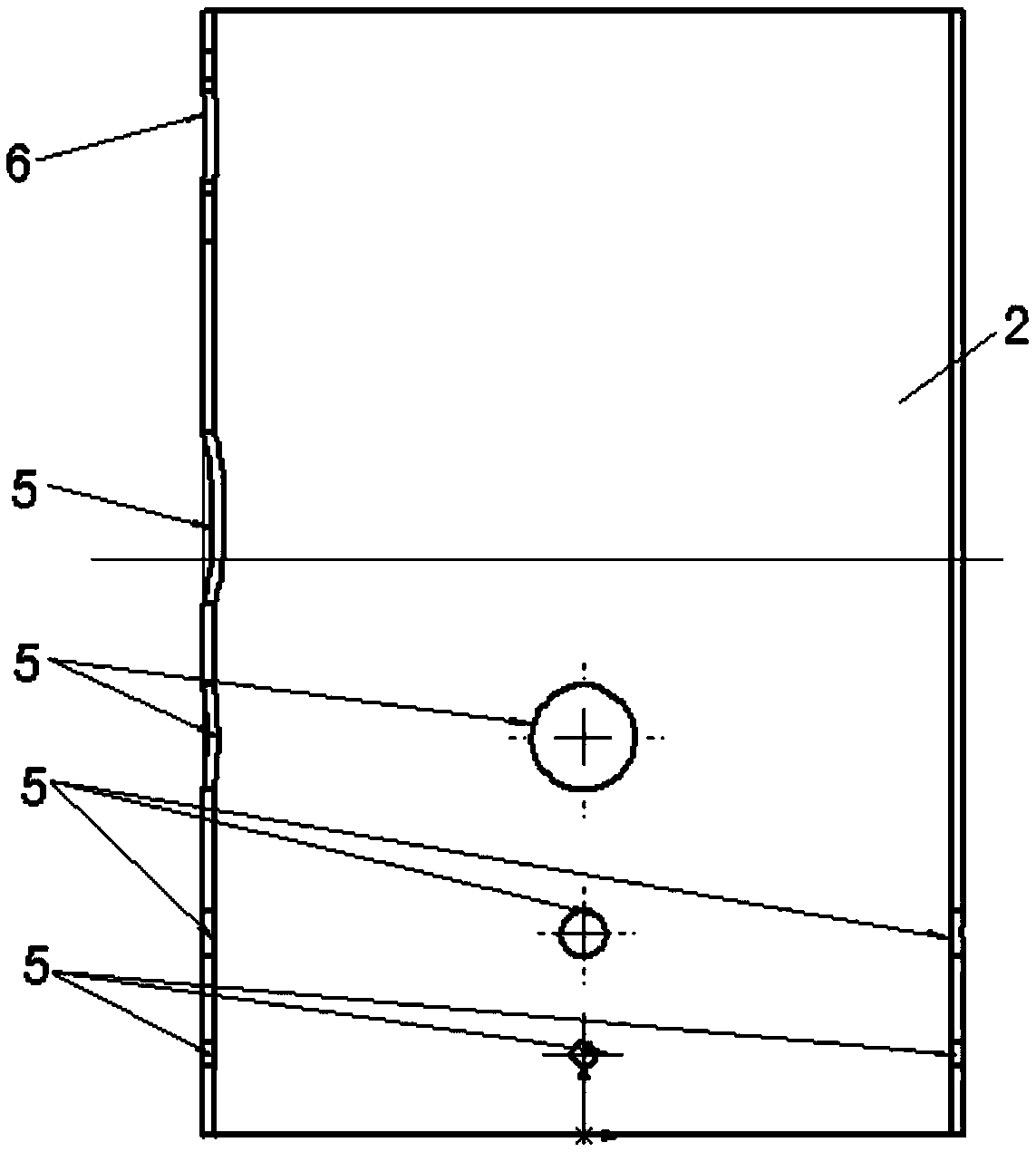

[0021] Such as figure 1 As shown, a hydraulic buffer includes a cylinder base 1, a buffer cylinder 2, a piston 3, and a rotating sleeve 4; the buffer cylinder 2 is fixed in the cylinder base 1, and the buffer cylinder 2 includes a fixed buffer cylinder 21 and a moving buffer cylinder 22 The fixed buffer cylinder 21 is sleeved inside the motion buffer cylinder 22, and the surface corresponding to the fixed buffer cylinder 21 and the motion buffer cylinder 22 is provided with a throttling hole 5 and a return hole 6, and the fixed buffer cylinder 21 is a hollow container. For storing oil, the hollow part formed by the fixed buffer cylinder 21 and the piston 3 is the inner cavity 7; there is a certain gap between the moving buffer cylinder 22 and the cylinder seat 1, and the gap is used as an oil return cavity to form an outer cavity 8; the rotating sleeve 4. Connect with the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com