Linear electromagnetic damper and control method thereof

An electromagnetic damper, linear technology, applied in the direction of magnetic spring, spring/shock absorber, spring, etc., can solve the problems of complex structure, fragile, mechanical wear, etc., to achieve strong environmental adaptability, not easy to damage, use Long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

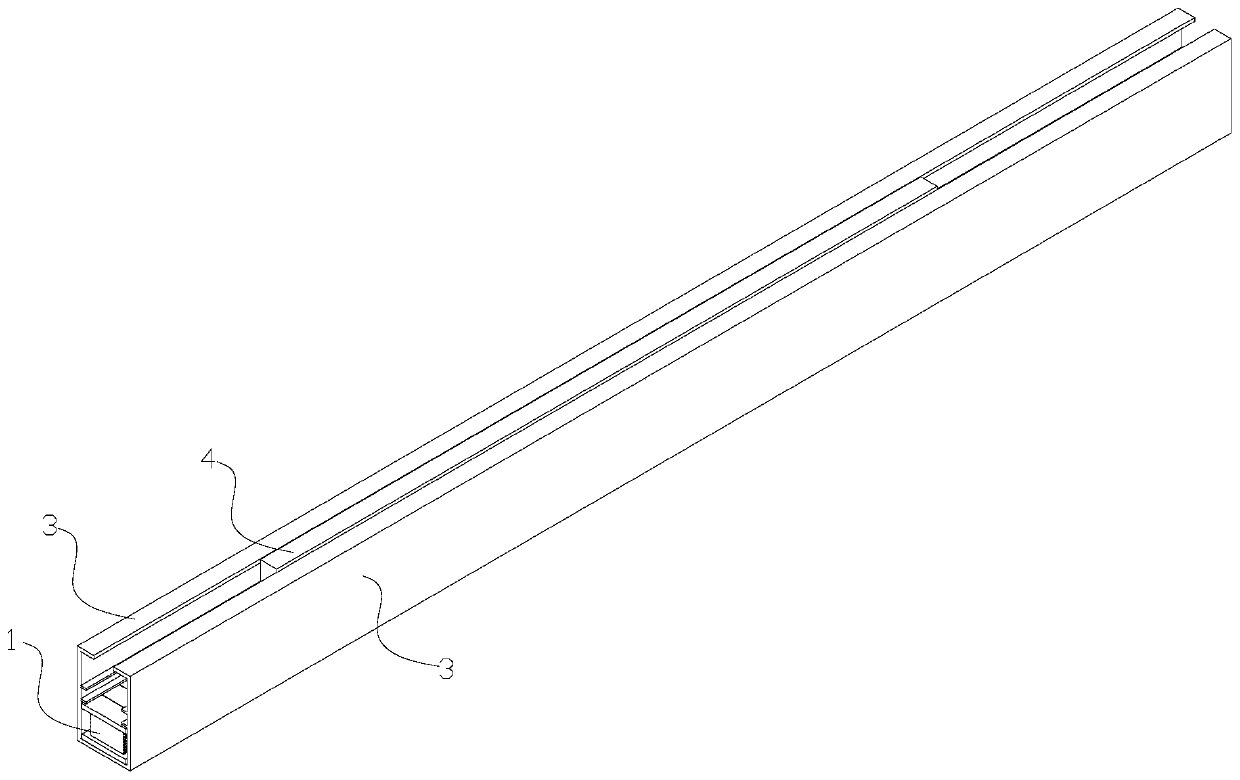

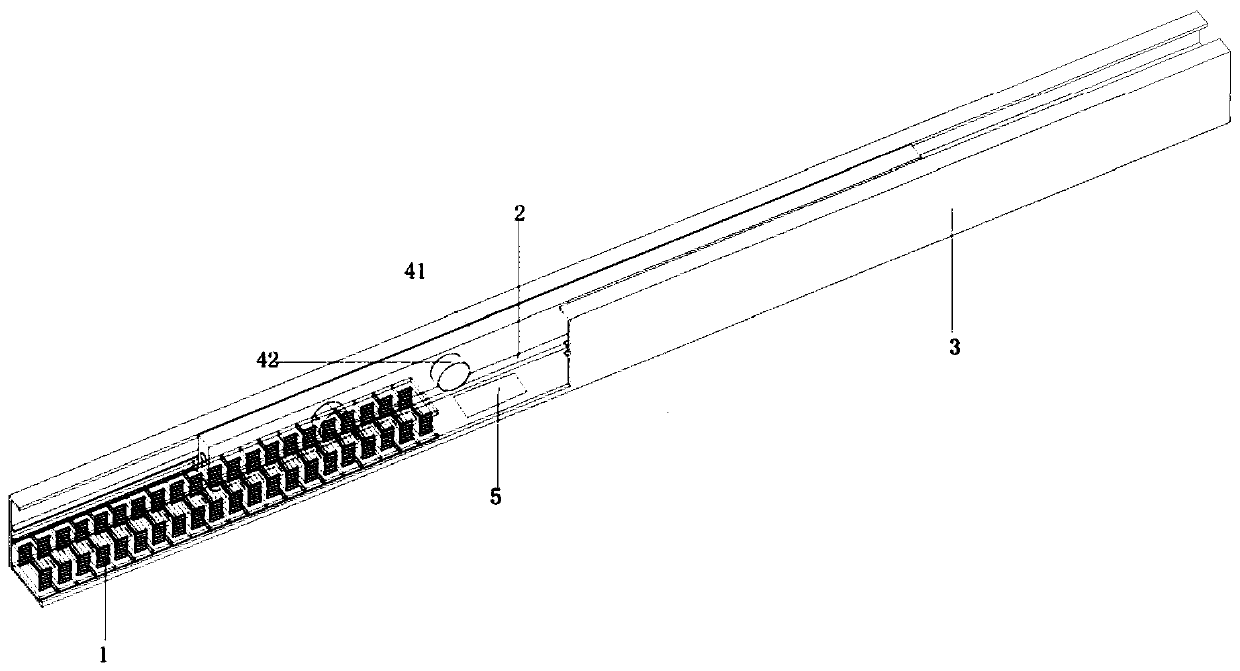

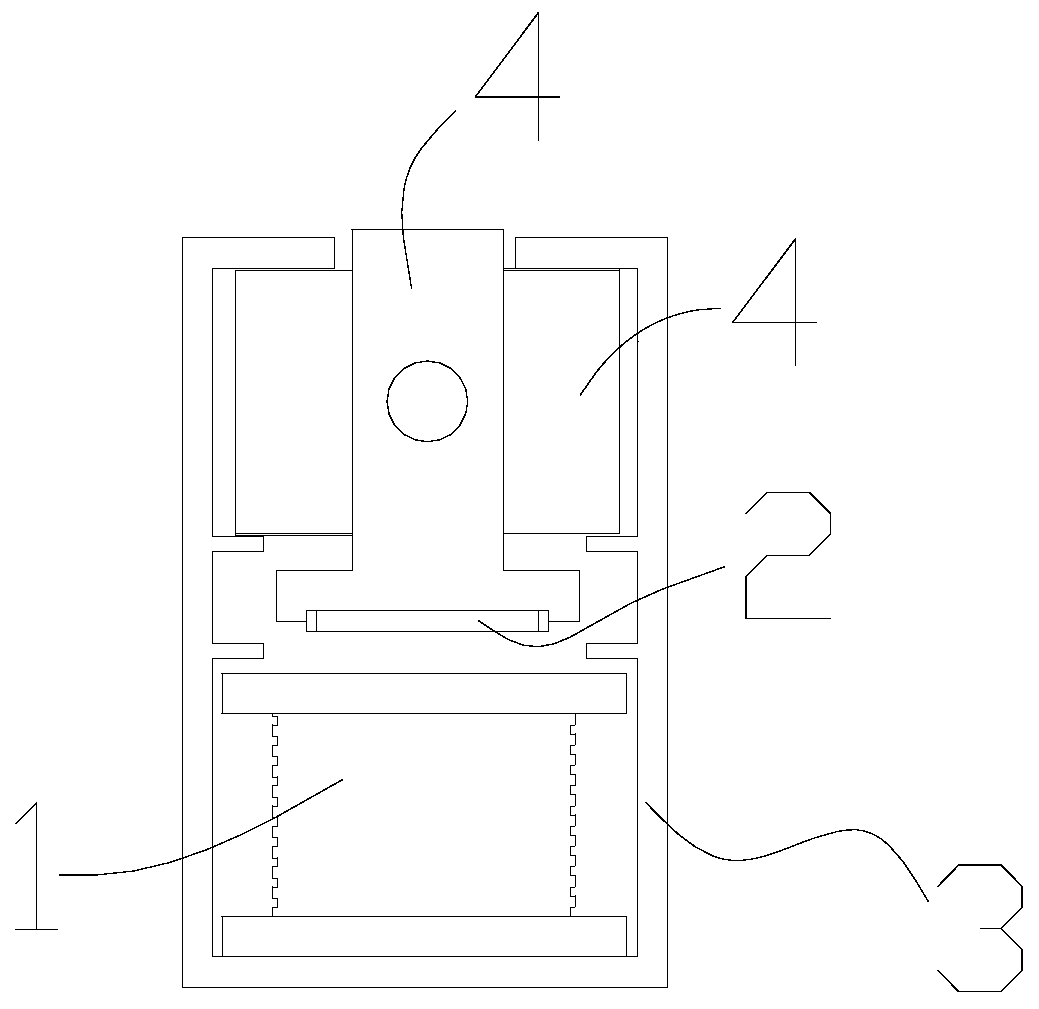

[0042] Such as Figure 1-5 As shown, a linear electromagnetic damper includes a linear induction coil unit 1, a linear magnet unit 2, a guide rail 3, a moving assembly 4 and a buffer control unit 5;

[0043] The linear induction coil unit 1 is arranged in the bottom of the guide rail 3; the moving assembly 4 is arranged on the guide rail 3 and moves with the guide rail 3; the linear magnet unit 2 is arranged on the guide rail 3 Under the bottom of the moving assembly 4; the buffer control unit 5 is connected to the linear induction coil unit 1; when the linear induction coil unit 1 and the linear magnet unit 2 are relatively displaced and electromagnetic cutting magnetic force lines occur, the The linear induction coil unit 1 outputs an induction signal to the buffer control unit 5;

[0044] The linear magnet unit 2 is used to make the linear induction coil unit 1 cut the magnetic field lines generated by the linear magnet unit 2 during the movement process;

[0045] The gui...

Embodiment 2

[0049] Embodiment 2 is the further optimization of embodiment 1;

[0050] Such as Figure 1-5 As shown, the linear induction coil unit 1 is a linear induction coil unit, a curved induction coil unit or an arc induction coil unit; the linear magnet unit 2 is a linear magnet unit, a curved type magnet unit or arc line type magnet unit.

Embodiment 3

[0052] Embodiment 3 is the further optimization of embodiment 1;

[0053] Such as Figure 1-5 As shown, the linear induction coil unit 1 includes N coil combinations 11; each coil combination 11 is arranged linearly in the bottom of the guide rail 3 from left to right; the coil combination 11 includes A first-phase induction coil 111, a second-phase induction coil 112, and a third-phase induction coil 113 arranged linearly in sequence; one line end of the first-phase induction coil 111 of each coil combination 11 is sequentially connected in series; each coil combination 11 One wire end of the second phase induction coil 112 of each coil combination 11 is sequentially connected in series; one wire end of the third phase induction coil 113 of each coil combination 11 is connected in series successively; The other wire end of the first-phase induction coil 111 , the other wire end of the second-phase induction coil 112 and the other wire end of the third-phase induction coil 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com