Safe start check valve for fire pump

A technology for safe start-up and fire-fighting pumps, which is applied to pump components, variable-capacity pump components, machines/engines, etc., can solve the problems of complex control valve structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

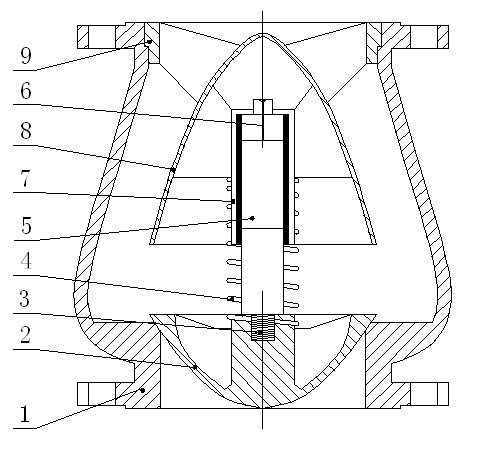

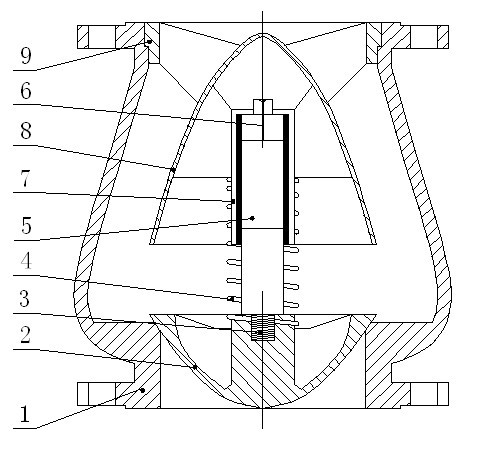

[0014] In order to understand the present invention more clearly, describe in detail in conjunction with accompanying drawing and embodiment:

[0015] like figure 1 As shown, the valve body 1 includes a resistance adjustment release mechanism, the resistance adjustment release mechanism is composed of a valve disc 2, a valve stem 3 spring 4, a hydraulic damper 5 and a resistance adjustment screw 6, the valve stem 3 is connected with the valve disc 2, One end of the valve stem 3 in the resistance adjustment release mechanism is connected to the hydraulic damper 5, a guide sleeve 7 is provided outside the valve stem 3 and the hydraulic damper 5, the other end of the valve stem 3 is fixed on the valve disc 2, and the valve stem 3 is connected to the hydraulic pressure One end of the damper 5 is slidably matched with the guide sleeve 7, the guide sleeve 7 is embedded in the guide body 8, the guide body 8 is fixed on the inner wall of the valve body 1 through the connecting key 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com