Remote control electric bracket for camera

An electric bracket and camera technology, applied in the field of brackets, can solve the problems of manpower consumption, increased workload of photographers, and impact on shooting efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

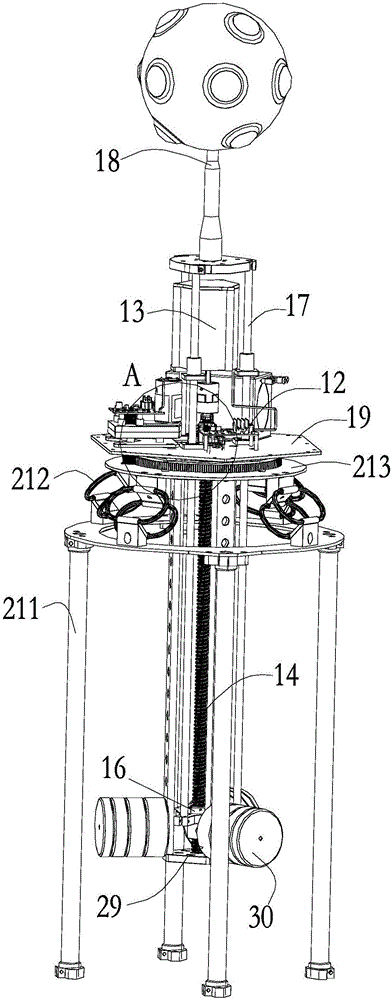

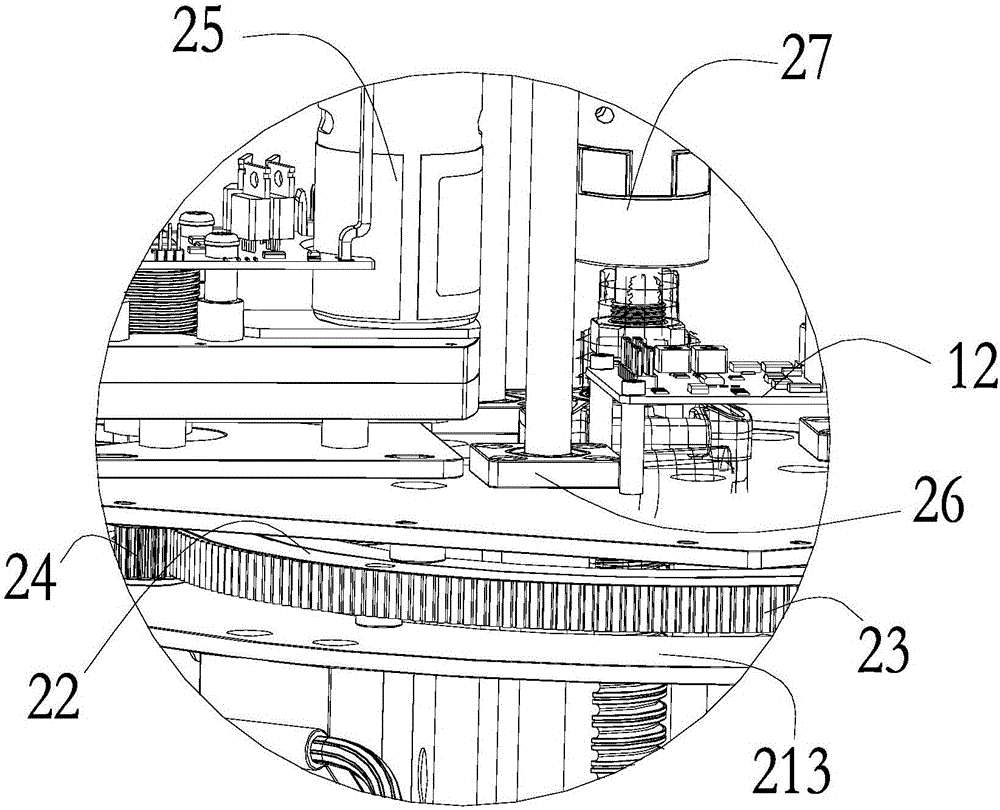

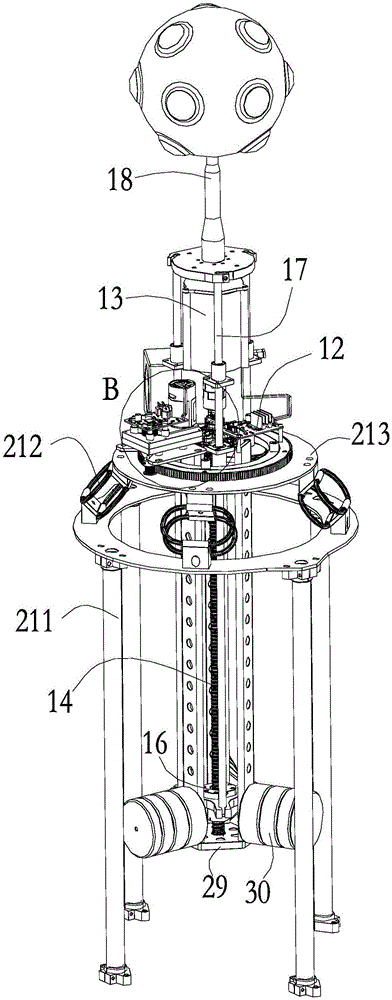

[0031] See Figure 1-Figure 6 , the present invention relates to a remote control electric bracket for a camera, including a remote terminal, a controller 12, a first motor 13, a screw 14, a nut 16, a rail shaft 17, a placement piece 18, an adapter plate 19, a first bearing 20, Frame body, second bearing 22, first gear 23, second gear 24, second motor 25, third bearing 26, shaft coupling 27, upper holder 28, lower holder 29 and counterweight 30.

[0032] Wherein, the frame body includes the lower frame 211, the steel wire ring 212 and the upper frame plate 213, the lower frame 211 is fixedly connected with the upper frame plate 213 through the steel wire ring 212, so that the frame body can better withstand vibration, slow down the violent impact of the outside world, and avoid Components installed above the frame are damaged due to severe impact from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com