A high voltage current monitoring circuit

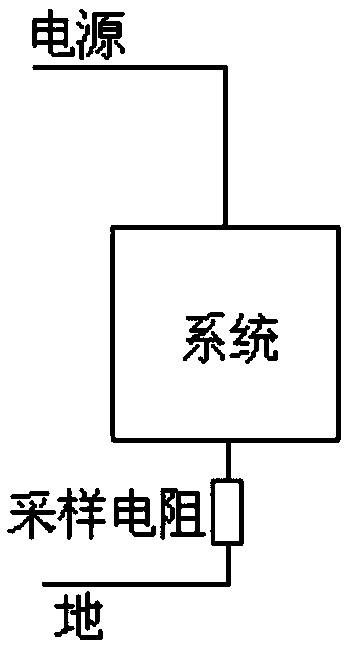

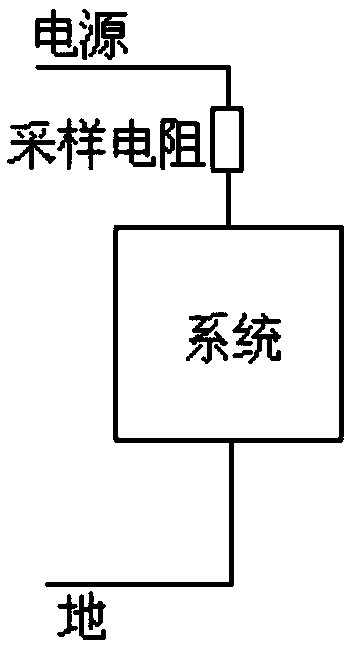

A technology for monitoring circuits and high-voltage currents, applied in the direction of measuring current/voltage, measuring only current, measuring electrical variables, etc., can solve problems such as affecting sampling accuracy, affecting output accuracy, and ordinary production lines cannot produce circuits, achieving easy integration, high The effect of input voltage range and sampling amplification accuracy, broad application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

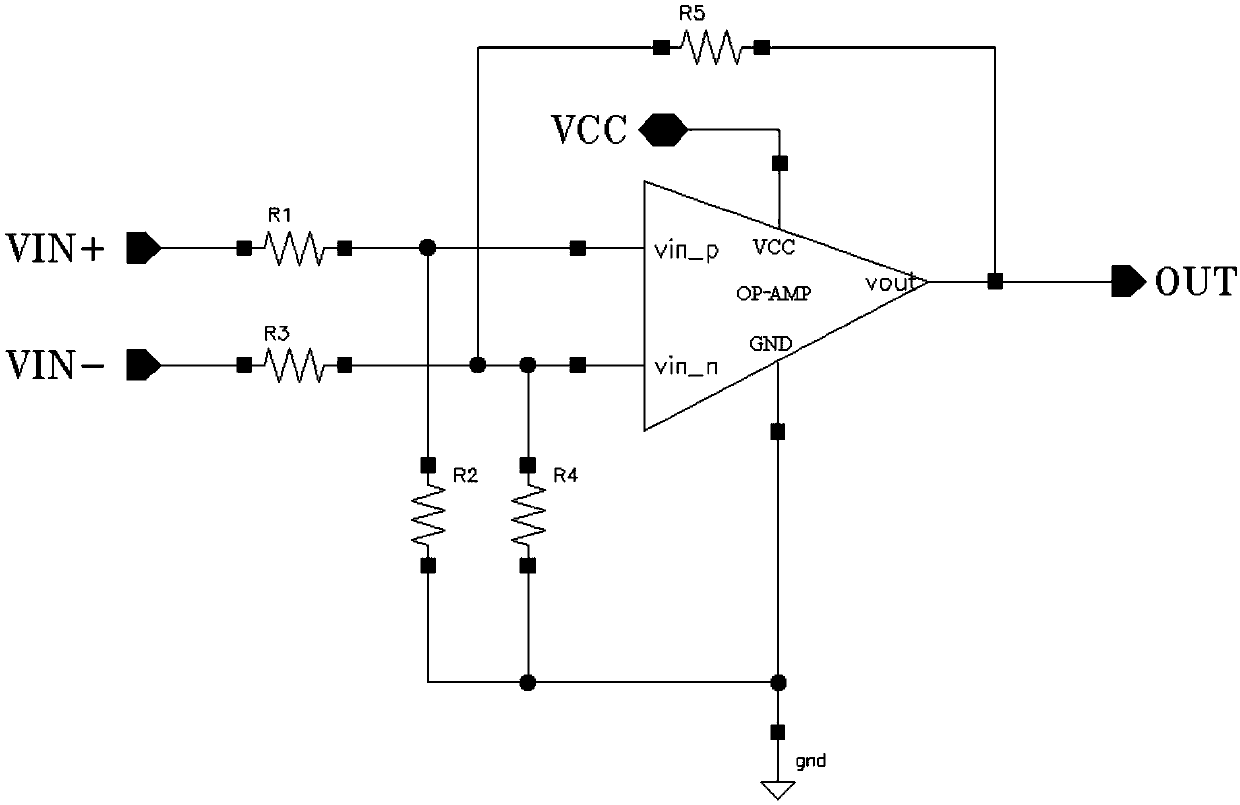

[0031] A high-voltage current monitoring circuit of the present invention, such as Figure 4 As shown, two-stage operational amplifiers are used to realize the functions of high-voltage sampling-current-voltage conversion and amplification respectively.

[0032] In the present invention, the sampling voltage (V IN+ —V IN- ) into the current signal I, according to the virtual short-virtual break method of the operational amplifier, it can be calculated

[0033] (V IN+ -V IN- )=R1×I (1)

[0034] The current signal I is transmitted from the high voltage side to the low voltage side through the three-stage Darlington transistors Q1Q2, Q3Q4, and Q5Q6, and is converted into a voltage signal by the resistor R3, and then amplified and output by the second operational amplifier amp2. Wherein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com