Barrier-free power supply line erection system for track field

A power supply line, barrier-free technology, applied in the agricultural field, can solve problems such as hindering the use of agricultural machinery and being unable to complete operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be further described below by means of drawings and specific embodiments. The specific embodiments described here are only for explaining the invention, and are not intended to limit the protection scope of the present invention.

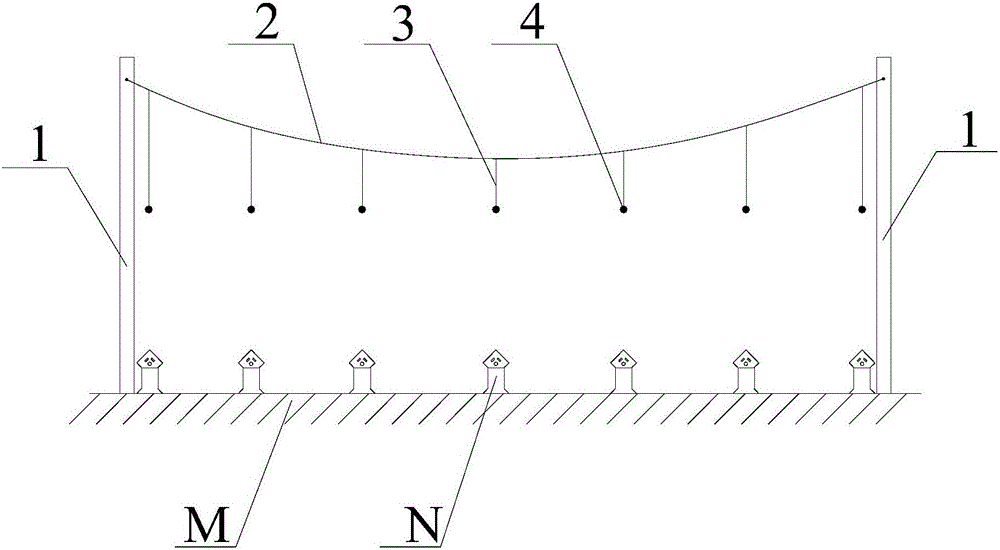

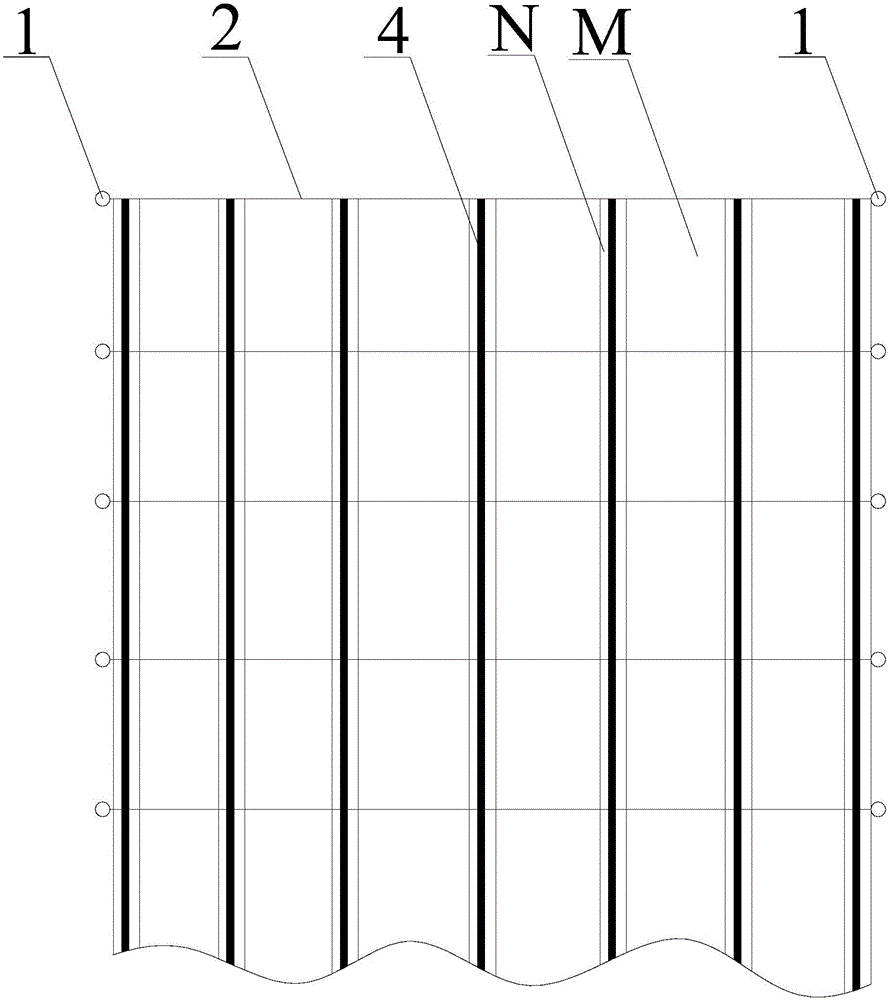

[0012] Rail field barrier-free power supply line erection system, such as figure 1 and figure 2 As shown, several utility poles 1 are included, and the utility poles 1 are evenly supported on both sides of the track field M, and every two utility poles 1 are a group, and a pair of utility poles 1 is erected between the two utility poles 1 of each group. An aerial steel cable 2, the aerial steel cable 2 is perpendicular to the track N of the track field M, and several slings 3 are hoisted under each aerial steel cable 2, and the described sling 3 is located directly above the track N , the lower ends of the slings 3 are on the same horizontal plane, and a power supply line 4 is jointly hoisted at the lower ends of each ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com