Aerial cable

A kind of overhead cable and aluminum stranded wire technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of weak current system equipment communication equipment hazards, cable allowable current reduction, transformer copper loss increase, etc., to reduce radiation Effects of interference, reduction in power loss, and increase in production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

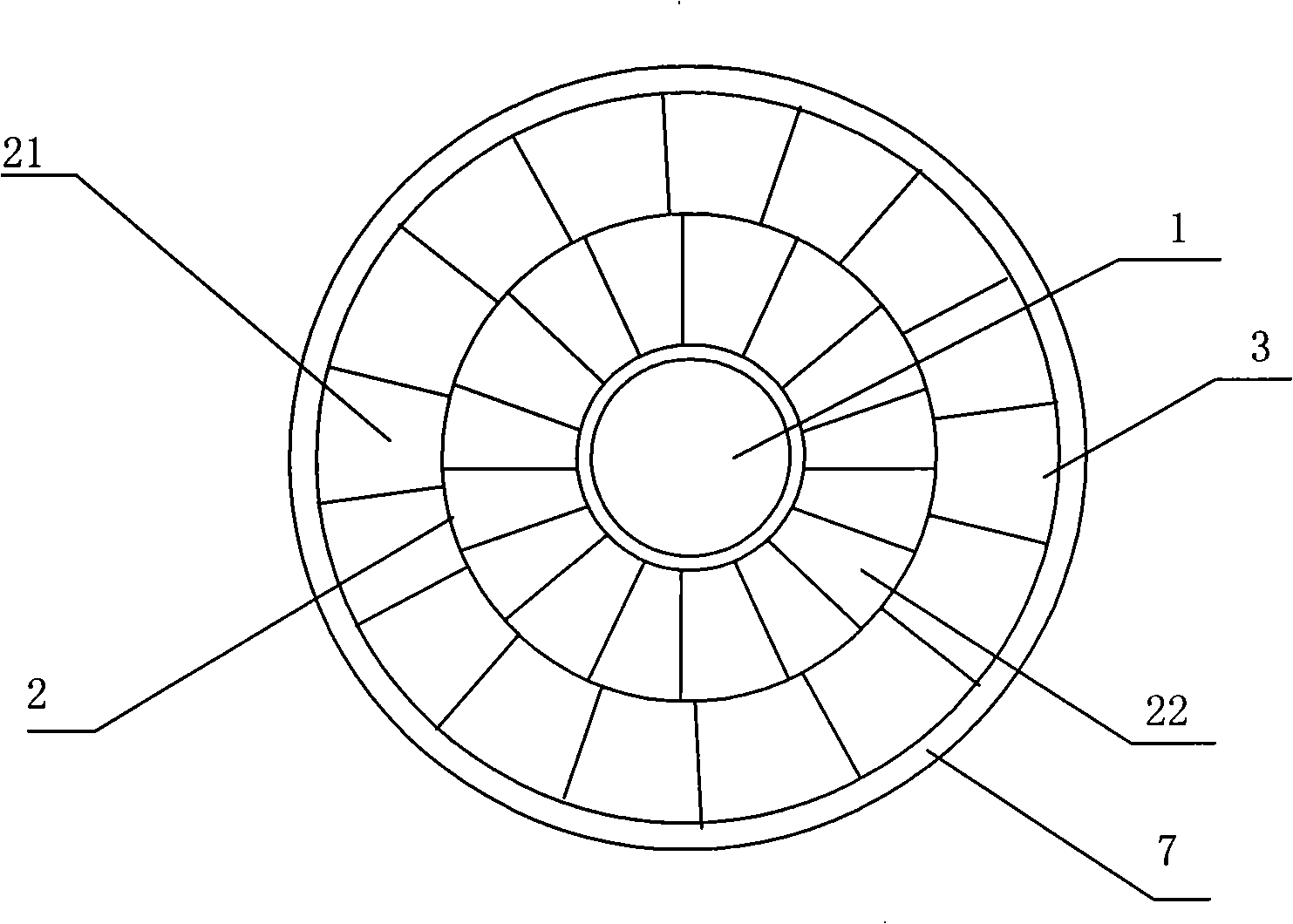

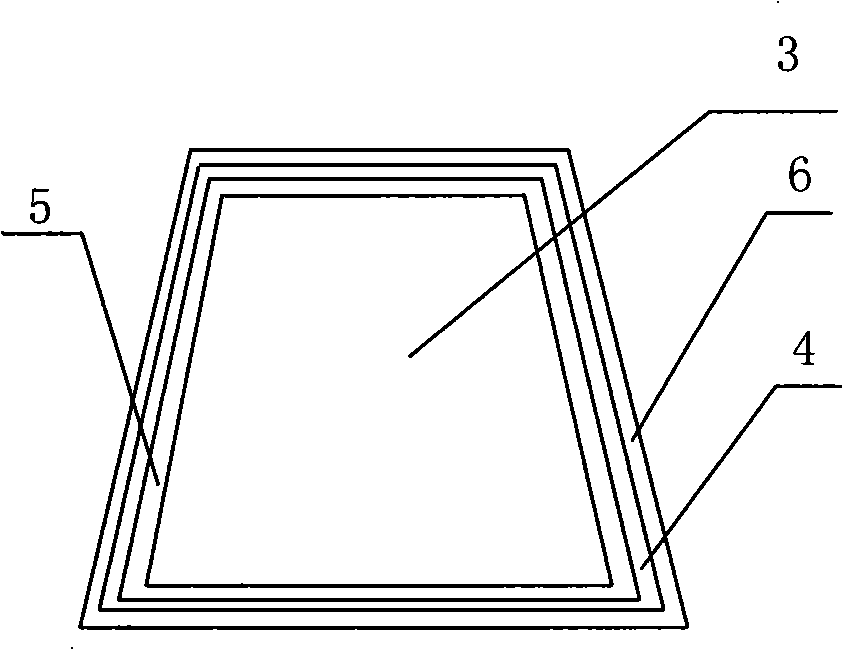

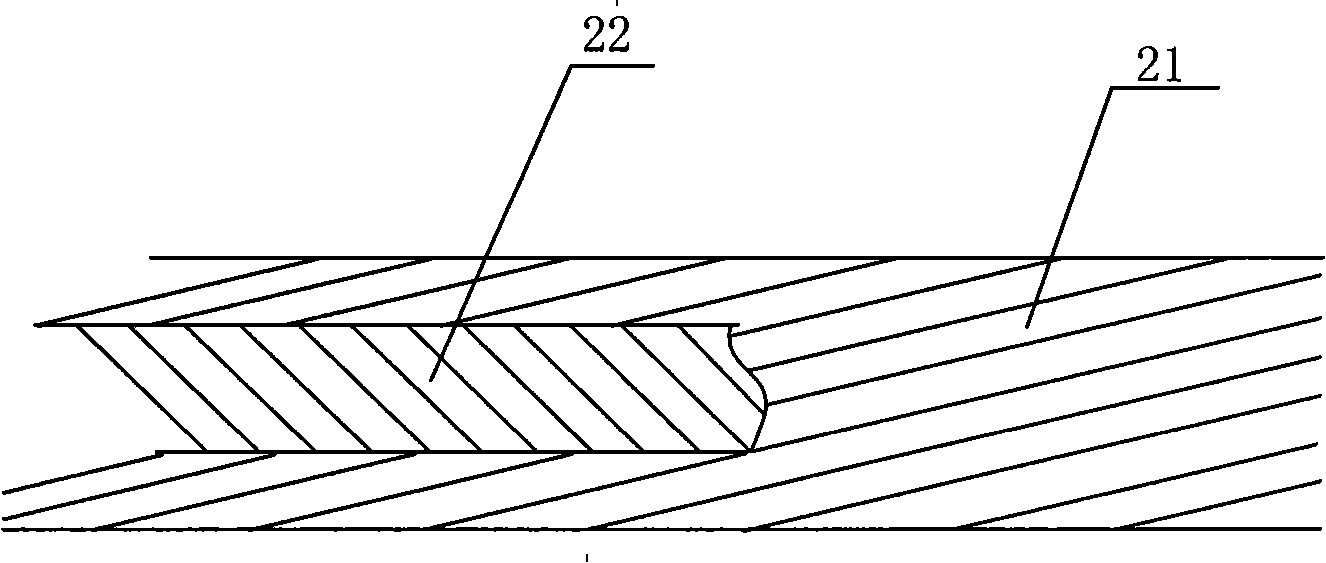

[0029] Embodiment 1: An overhead cable, including a reinforcing core 1 and an aluminum stranded wire layer 2, the aluminum stranded wire layer 2 is divided into an outer aluminum stranded wire layer 21 and an inner aluminum stranded wire layer 22, an outer aluminum stranded wire layer 21 and an inner aluminum stranded wire layer 22 The twisted wire layer 22 is formed by twisting a plurality of aluminum wires 3 respectively, and a single aluminum wire 3 is coated with an insulating layer 4 . The insulating layer 4 is an insulating paint layer or a nylon layer. A copper layer 5 is provided between the insulating layer 4 and the aluminum wire 3 . A waterproof layer 6 is arranged outside the insulating layer 4 . The waterproof layer 6 is a fluorine-containing resin layer, and the thickness of the fluorine-containing resin layer is 0.02 mm. The inner aluminum strand layer 22 is a plurality of aluminum wires 3 that are twisted clockwise around the reinforcement core 1 (right-hande...

Embodiment 2

[0030] Embodiment 2: An overhead cable, including a reinforcing core 1 and an aluminum stranded wire layer 2, the aluminum stranded wire layer 2 is divided into an outer aluminum stranded wire layer 21 and an inner aluminum stranded wire layer 22, an outer aluminum stranded wire layer 21 and an inner aluminum stranded wire layer 22 The twisted wire layer 22 is formed by twisting a plurality of aluminum wires 3 respectively, and a single aluminum wire 3 is coated with an insulating layer 4 . The insulating layer 4 is an insulating paint layer or a nylon layer. A copper layer 5 is provided between the insulating layer 4 and the aluminum wire 3 . A waterproof layer 6 is arranged outside the insulating layer 4 . The waterproof layer 6 is a fluorine-containing organic coating layer, and the thickness of the fluorine-containing organic coating layer is 0.08mm. The inner aluminum strand layer 22 is a plurality of aluminum wires 3 that are twisted clockwise around the reinforcement ...

Embodiment 3

[0031] Embodiment 3: An overhead cable, including a reinforcing core 1 and an aluminum stranded wire layer 2, the aluminum stranded wire layer 2 is divided into an outer aluminum stranded wire layer 21 and an inner aluminum stranded wire layer 22, an outer aluminum stranded wire layer 21 and an inner aluminum stranded wire layer 22 The twisted wire layer 22 is formed by twisting a plurality of aluminum wires 3 respectively, and a single aluminum wire 3 is coated with an insulating layer 4 . The insulating layer 4 is an insulating paint layer or a nylon layer. A copper layer 5 is provided between the insulating layer 4 and the aluminum wire 3 . A waterproof layer 6 is arranged outside the insulating layer 4 . The waterproof layer 6 is a polytetrafluoroethylene layer or the first fluorine-containing plastic layer, and the thickness of the polytetrafluoroethylene layer or the first fluorine-containing plastic layer is 0.6 mm. The inner aluminum strand layer 22 is a plurality of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com