Method for making simulated fingerprint

A production method and technology of fingerprints, which are applied in the directions of acquiring/arranging fingerprints/palmprints, detecting live finger shapes, and collecting printed images, can solve the problems of low recognition rate, poor image quality, and recognition rate that cannot meet the requirements, and achieve Guaranteed yield rate, improved recognition rate, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

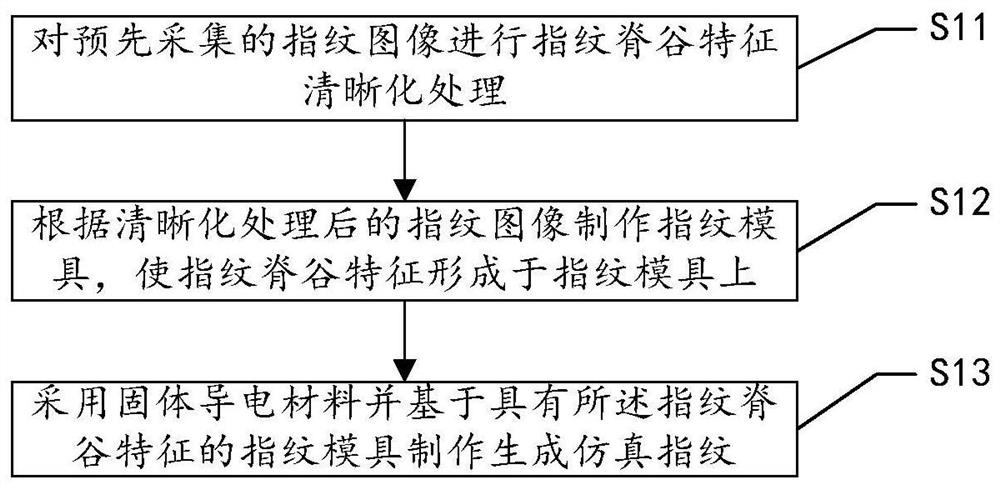

[0056] This embodiment provides a schematic flow chart of an embodiment of a method for making a simulated fingerprint, as figure 1 shown, which includes:

[0057] S11. Perform fingerprint ridge-valley feature clarification processing on the pre-collected fingerprint image.

[0058] In this embodiment, fingerprint images can be formed by pre-collecting fingerprints by the following methods:

[0059] (1) After dipping the colored ink pad on the finger, press it on the paper, and finally scan the fingerprint image through the scanner; or,

[0060] (2) collecting fingerprints through optical sensors, and obtaining fingerprint images by sensing the brightness and darkness of light reflected by fingerprints; or,

[0061] (3) After using graphite powder to display the finger print on the object, carry out image acquisition to obtain the fingerprint image on the object.

[0062] In order to ensure that the produced simulated fingerprint has a relatively high similarity with the re...

Embodiment 2

[0092] The present invention provides a schematic flow chart of an embodiment of a method for obtaining a fingerprint mold through a printed circuit board, as shown in image 3 shown, which includes:

[0093] S21. Convert the fingerprint image after clearing processing into a fingerprint image recognizable by the production control software of the printed circuit board factory and output the circuit board description file;

[0094] In this embodiment, the sharpened fingerprint image may be a fingerprint image that has undergone ridge-to-valley conversion.

[0095] In this embodiment, for example, the Allegro tool of Cadence Electronic Technology Co., Ltd. can be used to convert the image into a fingerprint image that can be recognized by the printed circuit board production control software.

[0096] In this embodiment, the fingerprint image can also be transformed into a fingerprint image recognizable by the printed circuit board production control software in other ways, an...

Embodiment 3

[0102] The present invention also provides a schematic flow chart of another embodiment of a method for obtaining a fingerprint mold by printing a printed circuit board, as shown in Figure 4 shown, which includes:

[0103] S31. Printing the sharpened fingerprint image on a film;

[0104] In order to facilitate subsequent photosensitive processing, transparent and translucent films can be used. In this embodiment, transparent film is taken as an example. After printing the fingerprint image that has undergone sharpening and ridge-valley conversion on the film, the ridge-valley features of the fingerprint are attached to the film, and the ridge features of the fingerprint are black. Printing on the transparent film The black part will be opaque; the fingerprint valley feature is white, and the white part will be transparent after printing on the transparent film, as shown in Figure 5(b).

[0105] S32. Paste the film printed with the sharpened fingerprint image on the printed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com