Automatic take-up mechanism for wheel fixer

A fixer and wheel technology, which is applied in the direction of motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problems of slow take-up speed and complicated operation, and achieves prevention of loosening, convenient and quick pull-out operation, and convenient and fast take-up operation. With the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

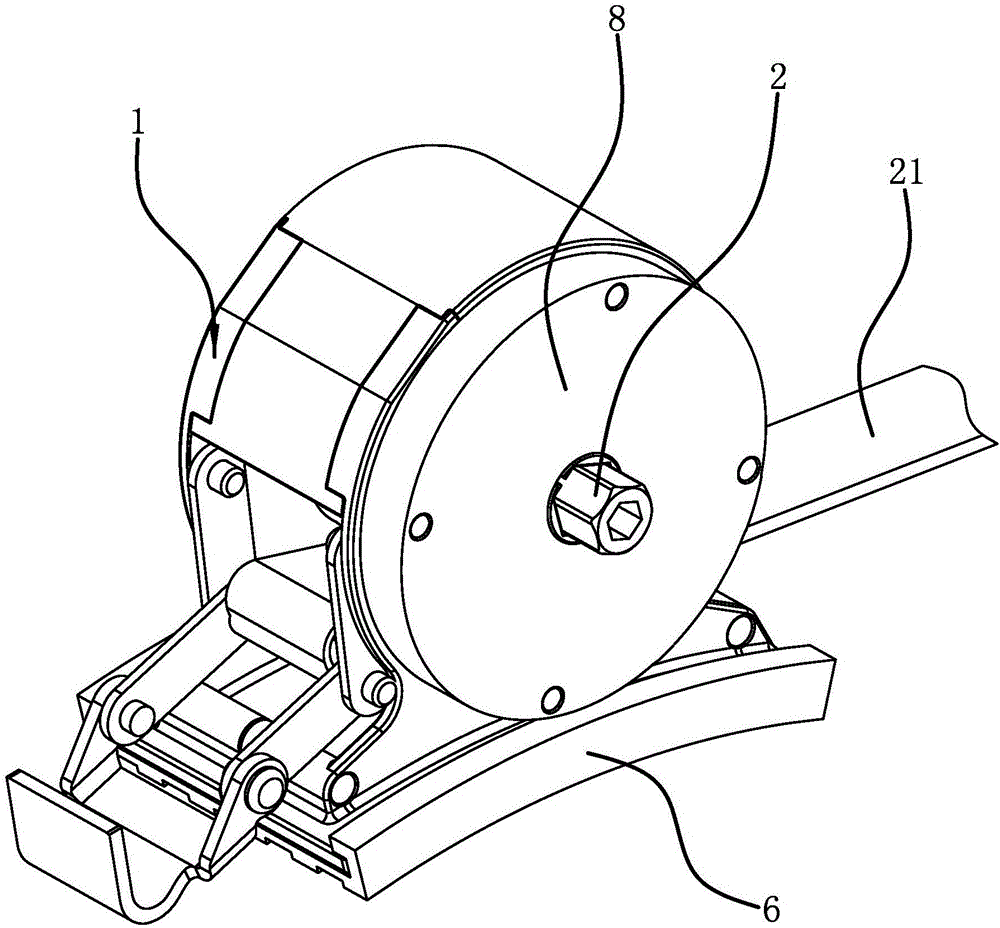

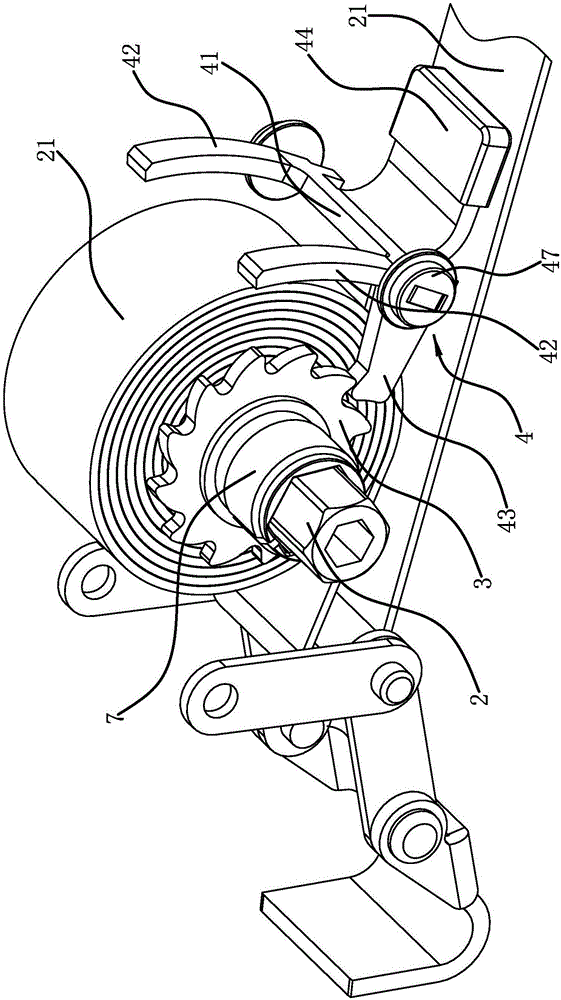

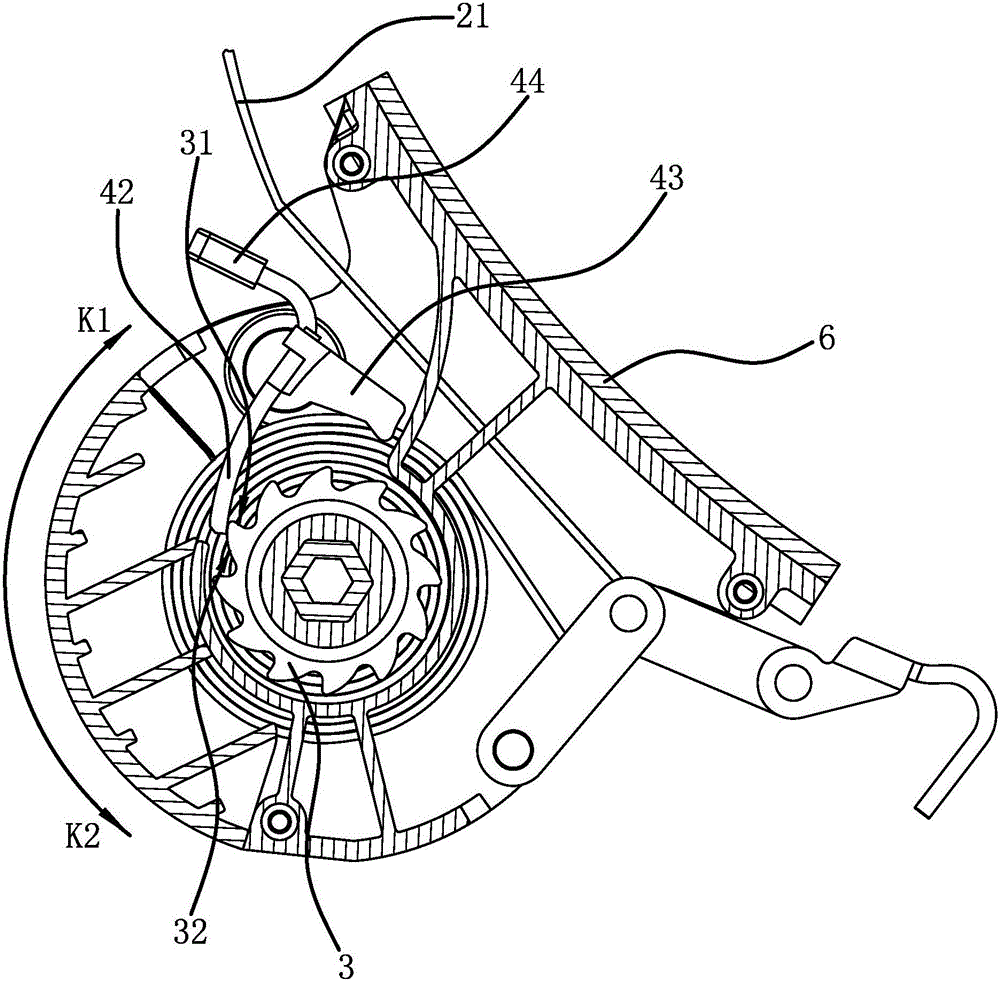

[0031] Such as figure 1 , figure 2 As shown, an automatic take-up mechanism of a wheel holder, the wheel holder includes a housing 1, a reel 2 is rotatably connected to the housing 1, and a fastening belt 21 is wound on the reel 2, and the fastening belt 21 is located in the housing 1, a ratchet 3 is fixedly connected to the reel 2, and each ratchet of the ratchet 3 has a positioning surface 31 and a guiding surface 32. The housing 1 is hinged with a locking piece 4, the locking piece 4 has a pawl 42, a locking lever 43 and a counterweight 44, the three are firmly connected, an angle is formed between the locking lever 43 and the pawl 42, and the matching The weight 44 and the locking rod 43 are located on both sides of the ratchet 42. The locking rod 43 has a pushing arc surface 431 and an abutting surface 432 respectively. The resting surface 432 is located at the end of the locking rod 43 . Such as image 3 As shown, it is the state of the housing 1 when the fastening ...

Embodiment 2

[0034] The automatic take-up mechanism of this wheel holder is basically the same as Embodiment 1, the difference is that Figure 8 As shown, the locking member 4 also includes a counterweight rod 45, the two ends of the counterweight rod 45 are rotatably connected to the inner wall of the housing 1, and the locking rod 43 and the pawl 42 are all fixedly connected to the counterweight rod 45. At the end, the middle part of the counterweight rod 45 is bent to form a protruding counterweight part 46 , without additional counterweight 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com