Mute flush toilet fast water inlet assembly

A flush toilet and water inlet technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve problems such as tap water pollution, pollution, and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

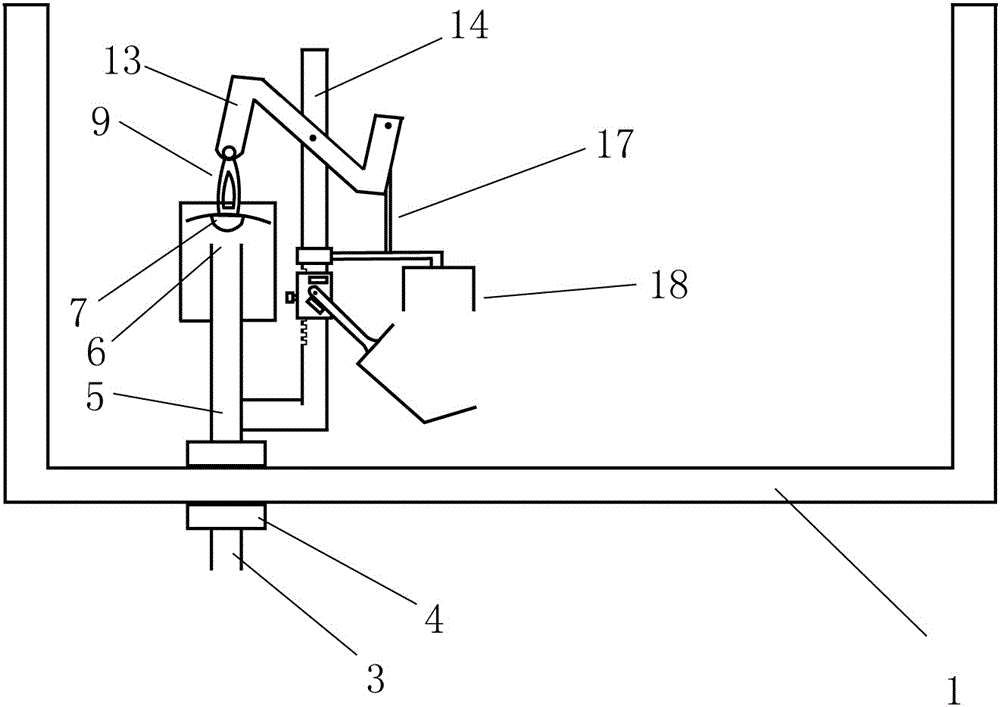

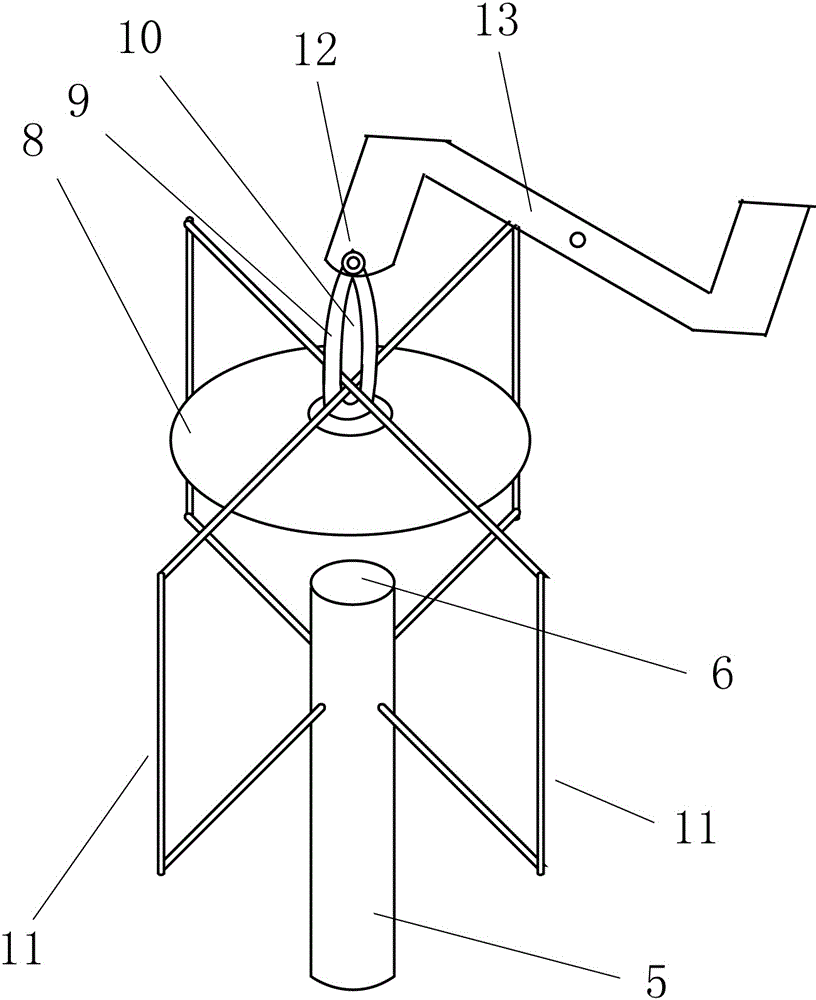

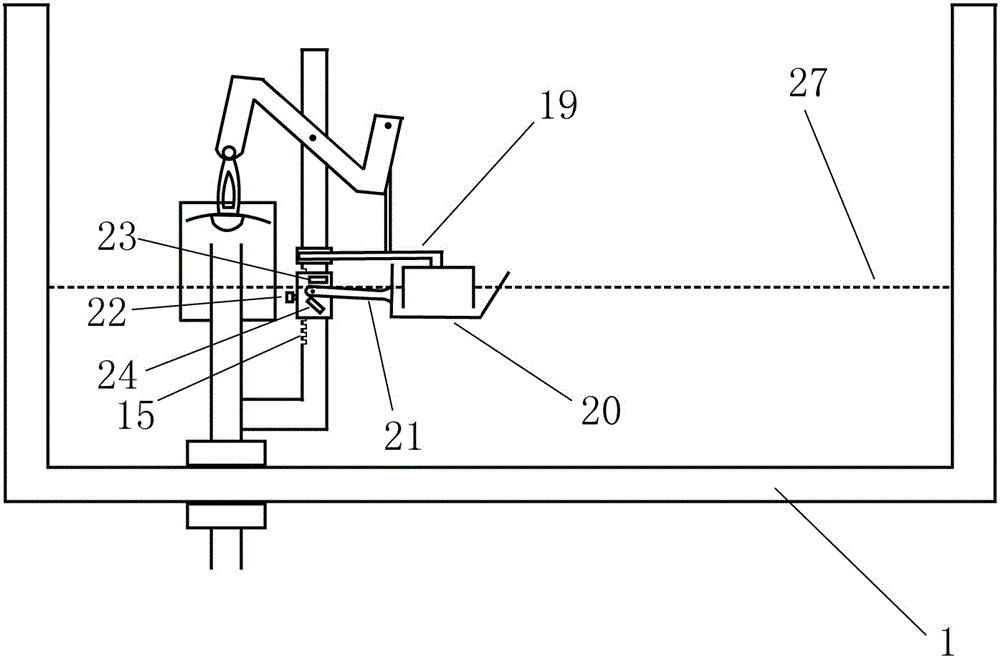

[0026]The silent fast water inlet assembly of the flush toilet, the water supply pipe (3) is connected to the water inlet pipe (5) in the water tank (1) through the water pipe joint (4), the uppermost end of the water inlet pipe (5) is the water inlet (6), and the water inlet pipe (5) A support column (14) is provided on one side, and the support column (14) is connected with the water inlet pipe (5) to support other parts of the water inlet assembly. The water inlet pipe (5) is vertically arranged, and the uppermost end is the water inlet (6). The water inlet (6) is higher than the highest water level line (2) in the water tank (1), the water inlet plug (7) is above the water inlet (6), and a disc-shaped dish-shaped shroud is arranged around the water inlet plug (7) (8), the water inlet plug (7) is located in the center of the dish-shaped shroud (8), the top of the water inlet plug (7) is connected to the column head (9), and the center of the column head (9) has a hole, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com