Water-aid injection molding water needle

An injection molding and water-assisted technology, which is applied in the field of water-assisted injection molding, can solve the problems of complex structure of the core rod of the water needle and the sleeve of the water needle, unstable spring performance, and large volume of the water needle device. The effect of modernized design, easy processing and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

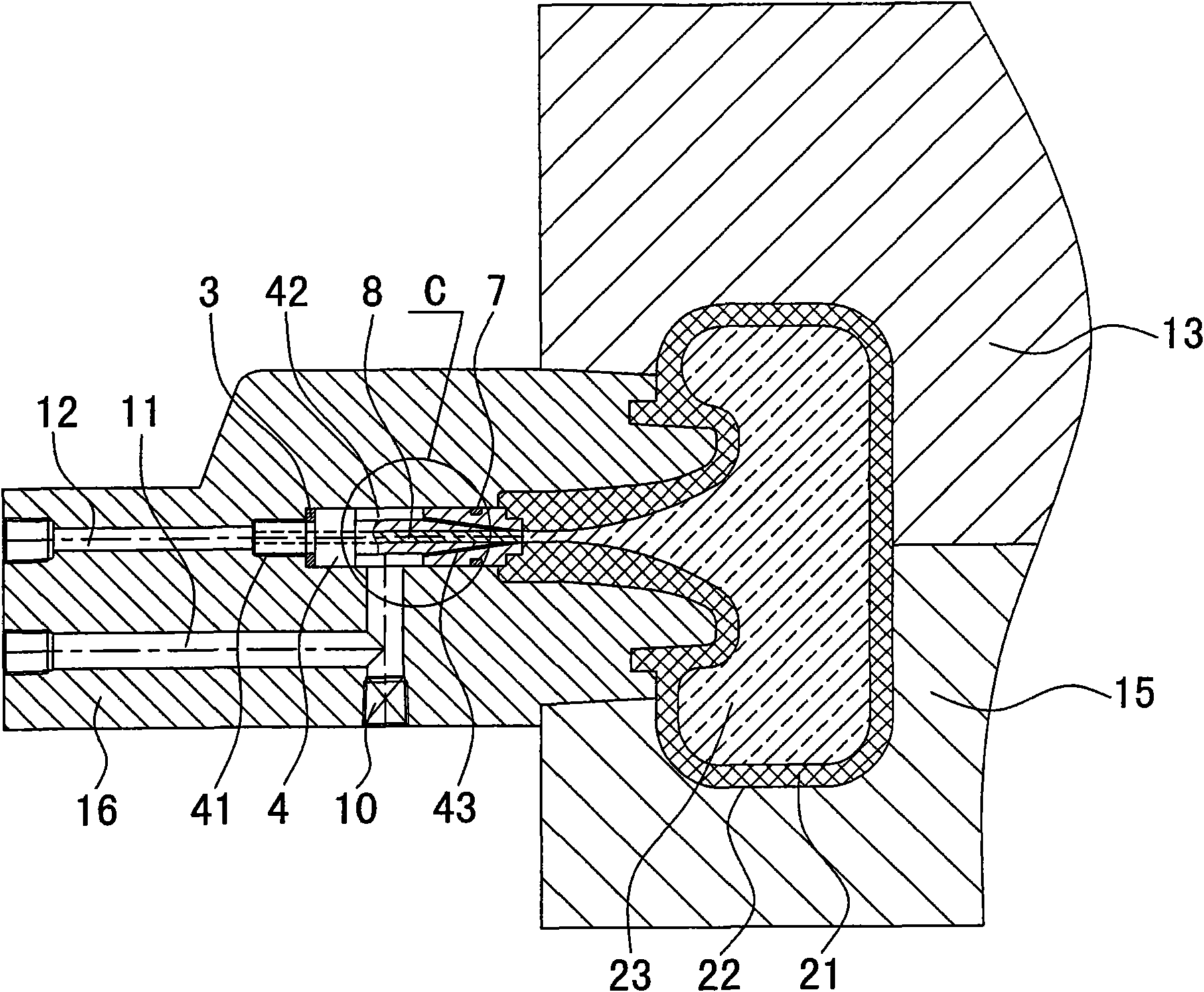

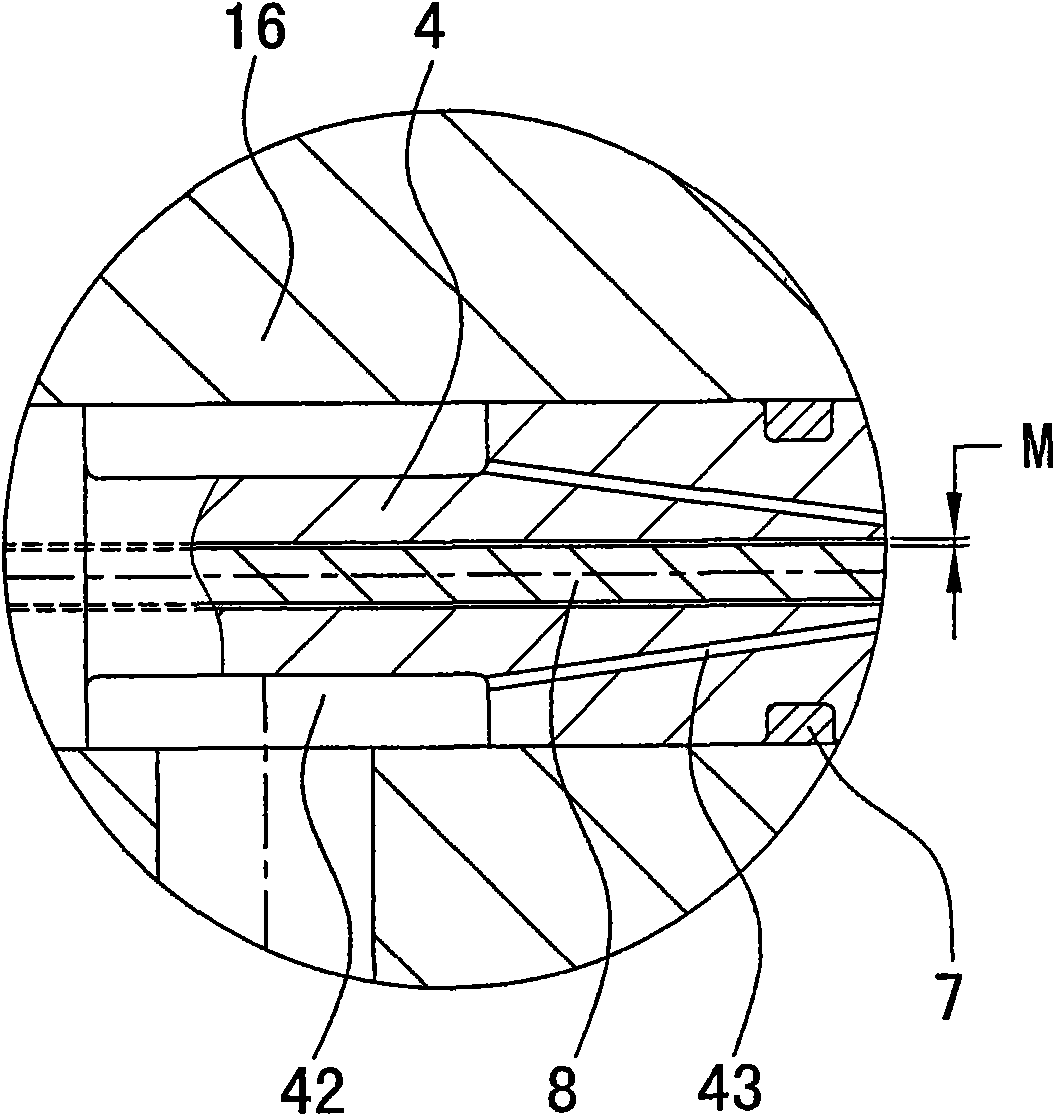

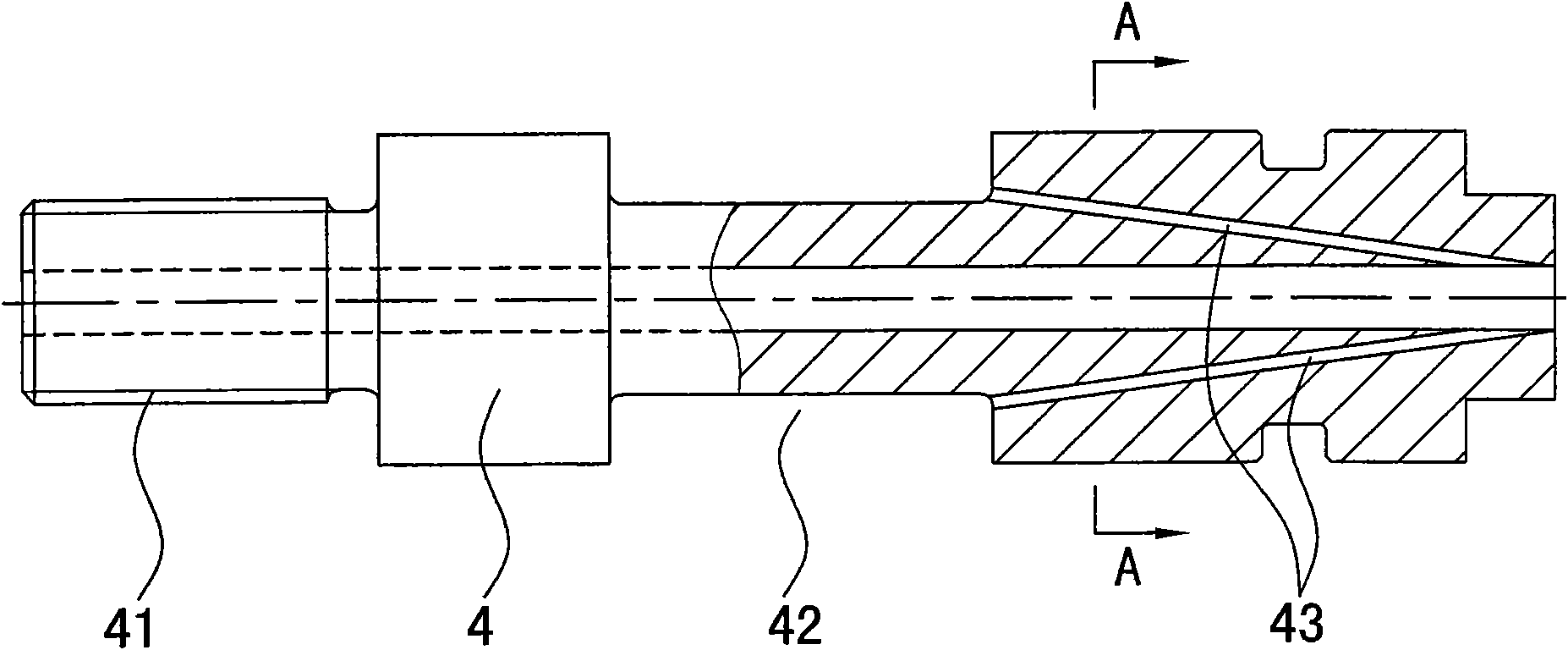

[0013] The invention discloses a water-assisted injection molding water needle, such as figure 1 As shown, it includes a mould, the mold includes a cavity 13 and a core 15, the cavity 13 and the core 15 constitute the cavity 22 of the product, the mold is shaped on a mounting hole, and a water needle is housed in the mounting hole, and the water needle includes a water needle The water needle core rod 8 in the needle sleeve 4 and the water needle sleeve 4 has a water inlet flow channel and an air intake flow channel in the mold, the water supply device is connected outside the water inlet flow channel, and the air supply device is connected outside the water inlet flow channel, which is characterized in that There is a gap M between the water needle casing 4 and the water needle core rod 8, such as figure 2 As shown, the gap M communicates with the inlet flow channel 12 and the mold cavity 22 of the mould. The middle part of the water needle sleeve 4 is formed with a water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com