Hydraulic oil cooling device of coal mining machine

A cooling device and hydraulic oil technology, which is applied in fluid pressure actuation devices, mechanical equipment, fluid pressure actuation system components, etc., can solve problems such as large water consumption, system paralysis, and difficulty in cleaning, and achieve increased contact area, System stability and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

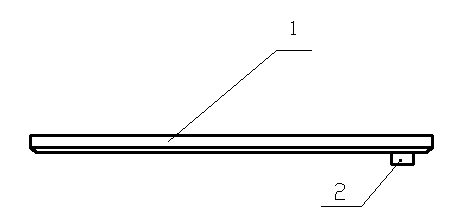

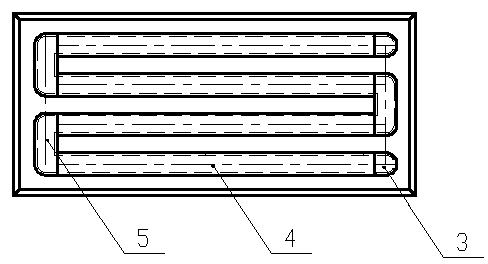

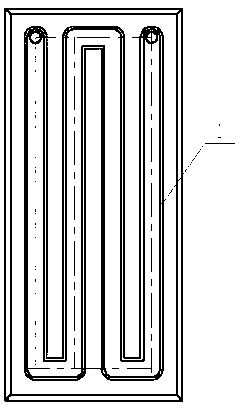

[0022] Such as Figure 1 to Figure 11 As shown, a shearer hydraulic oil cooling device of the present invention includes six cooling plates assembled and welded together up, down, left, right, front, back, and front. The cooling plate includes a bottom plate 1, a joint seat 2, an end plate 3, a strip plate 4 and a pressure plate 5, wherein the end plate 3, the strip plate 4 and the pressure plate 5 are respectively welded on the bottom plate 1, the pressure plate 5 is connected with it at the corner of the strip plate 4, the end plate 3 is connected with the two ends of the strip plate 4, and then The joint seat 2 is welded at the corresponding position opposite to the end plate 3 to form a serpentine water channel, and the number and size of each part are determined according to the size of the bottom plate 1 of each cooling plate of the fuel tank.

[0023] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com