A lower electrode and reaction chamber

An electrode and dielectric constant technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as the inability to adjust the electric field distribution and the etching uniformity of the wafer 13

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

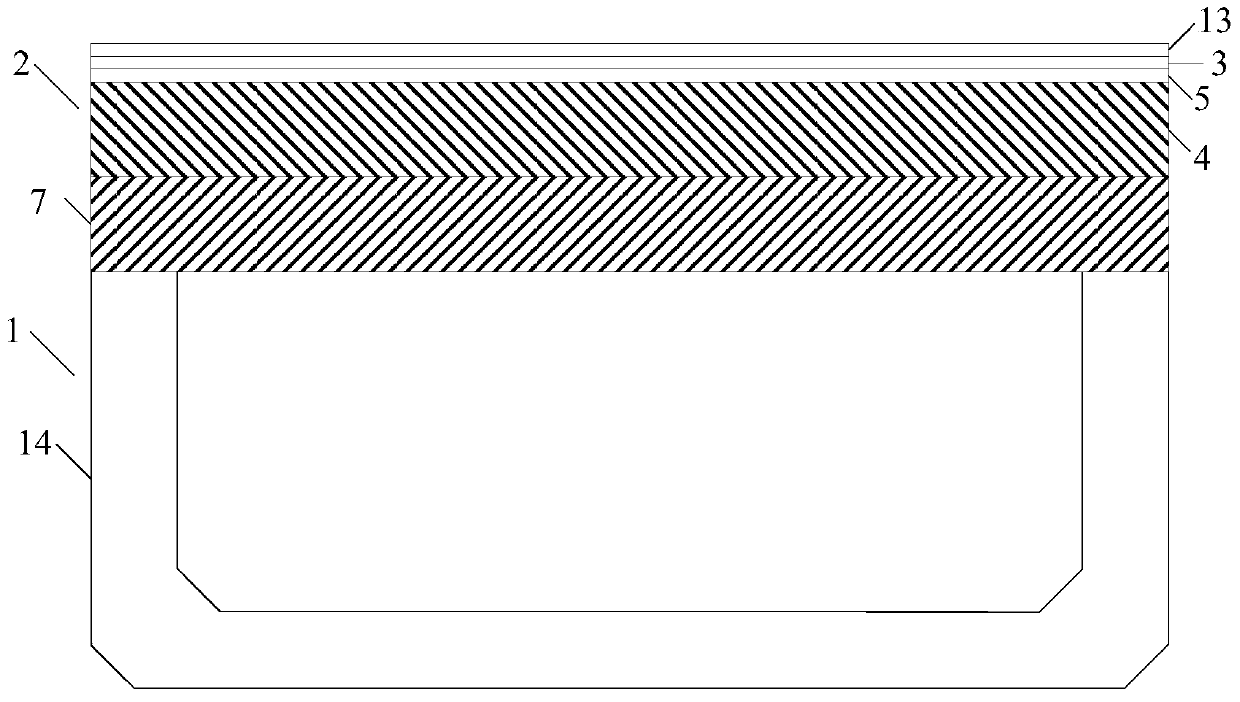

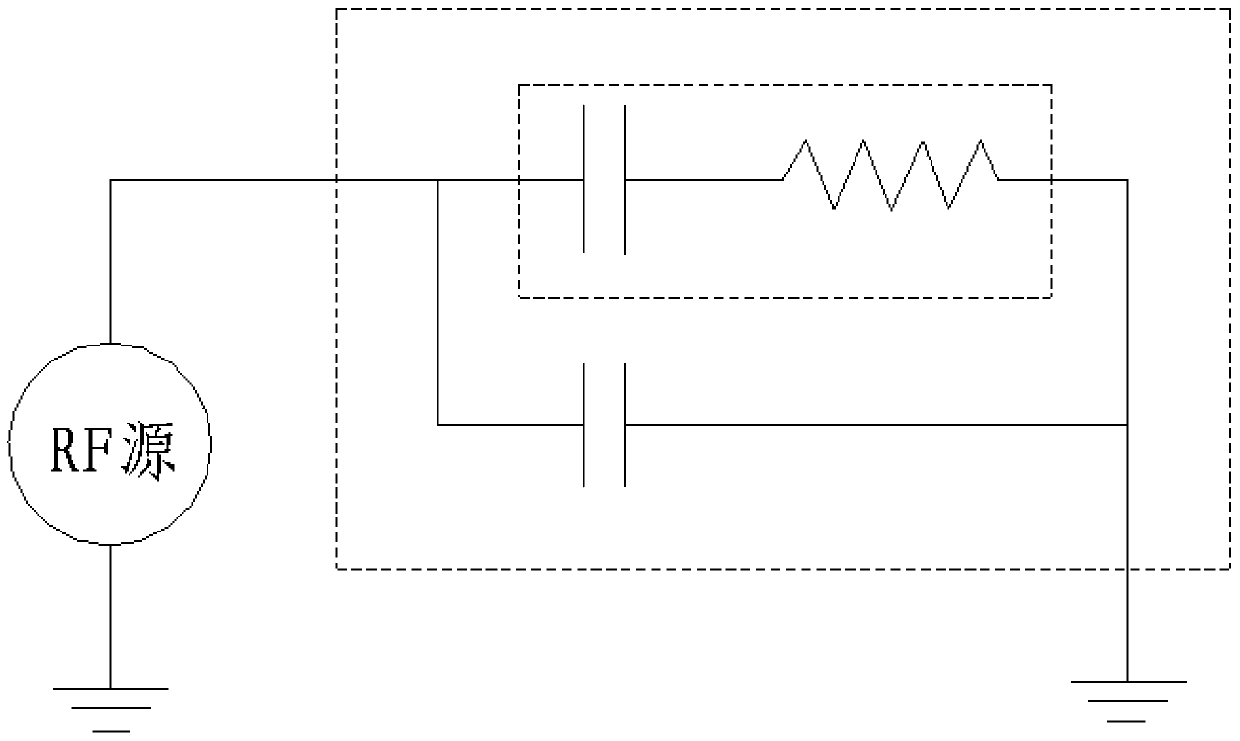

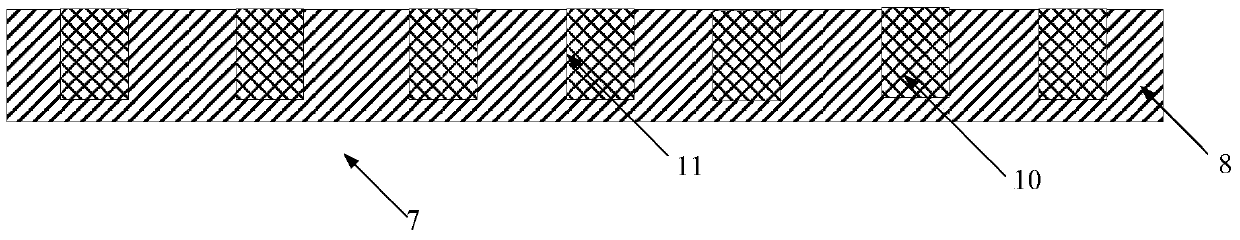

[0031] Such as Figure 3-6 As shown, this embodiment provides a lower electrode 1, the lower electrode 1 includes an electrostatic chuck 2 and a lower electrode interface plate 7 arranged below the electrostatic chuck 2, and the lower electrode interface plate 7 is used for installation and The component interface 6 connected to the electrostatic chuck 2, the lower electrode interface plate 7 includes the lower electrode interface plate body 8, the receiving part provided on the lower electrode interface plate 7, and the lower electrode interface plate 7 also includes the lower electrode interface plate 7. The partial permittivity adjustment block 10 with different permittivity of the lower electrode interface plate body 8 is described, and the accommodating part is used to accommodate the local permittivity adjustment block 10, and the partial permittivity adjustment block 10 is selectively accommodated in the accommodating part. The dielectric constant adjustment block 10 is...

Embodiment 2

[0050] This embodiment also provides a reaction chamber, in which the lower electrode in Embodiment 1 is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com