Design method of customized artificial knee joint prosthesis

A technology of artificial knee joint and design method, which is applied in the field of medical equipment, can solve the problems of discontinuous curvature of the sagittal condyle curve, low adaptability, and weak rollback ability, so as to improve the mechanical condition and avoid left and right swaying , Enhance the effect of rollback ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

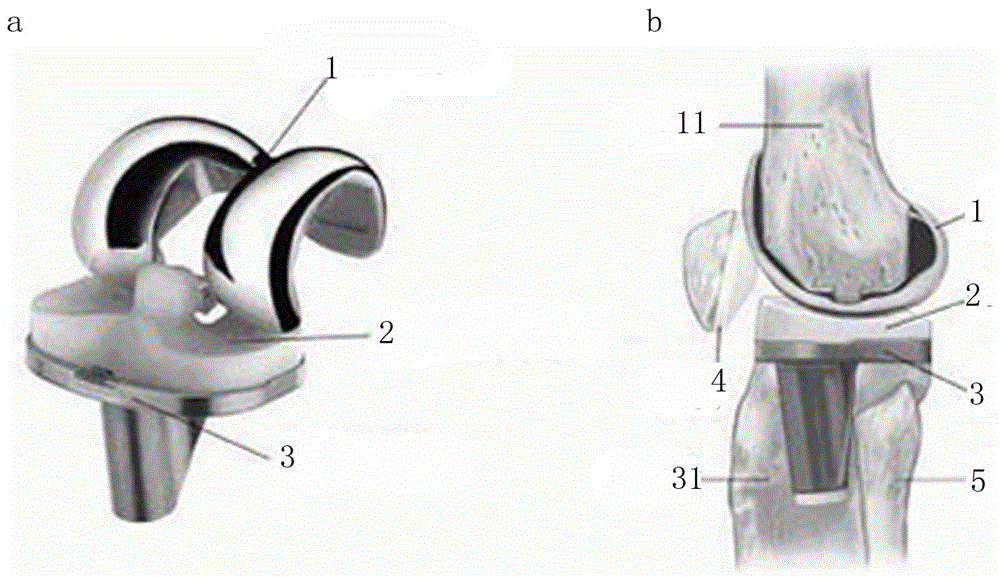

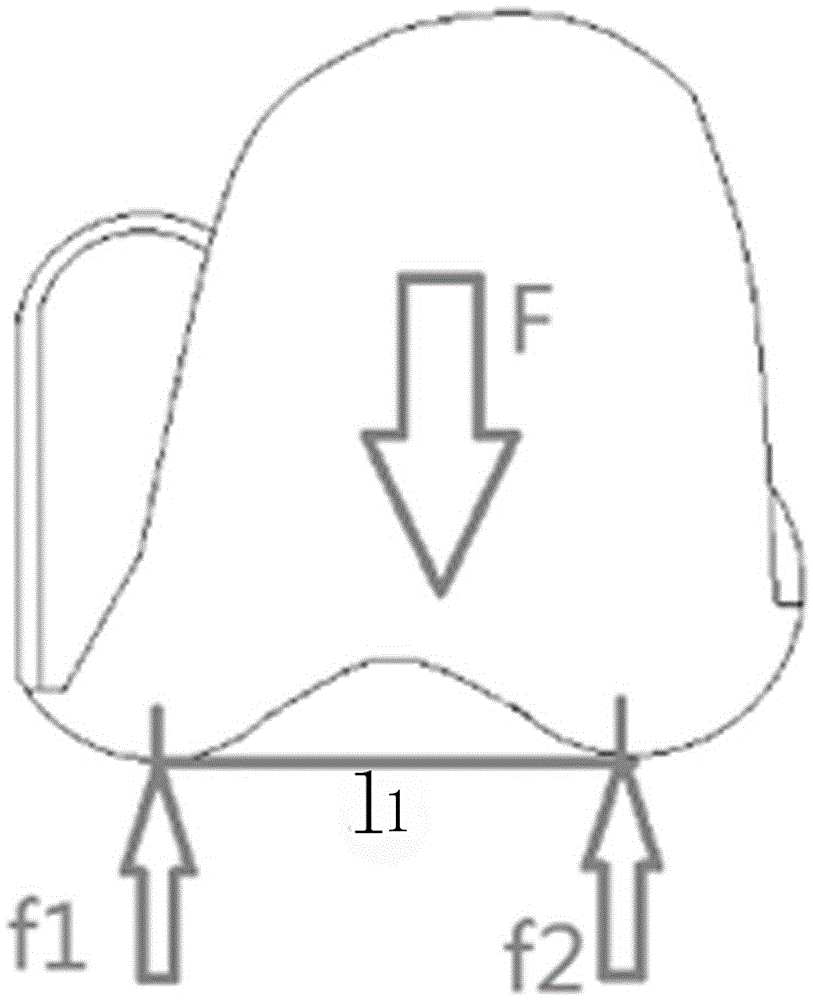

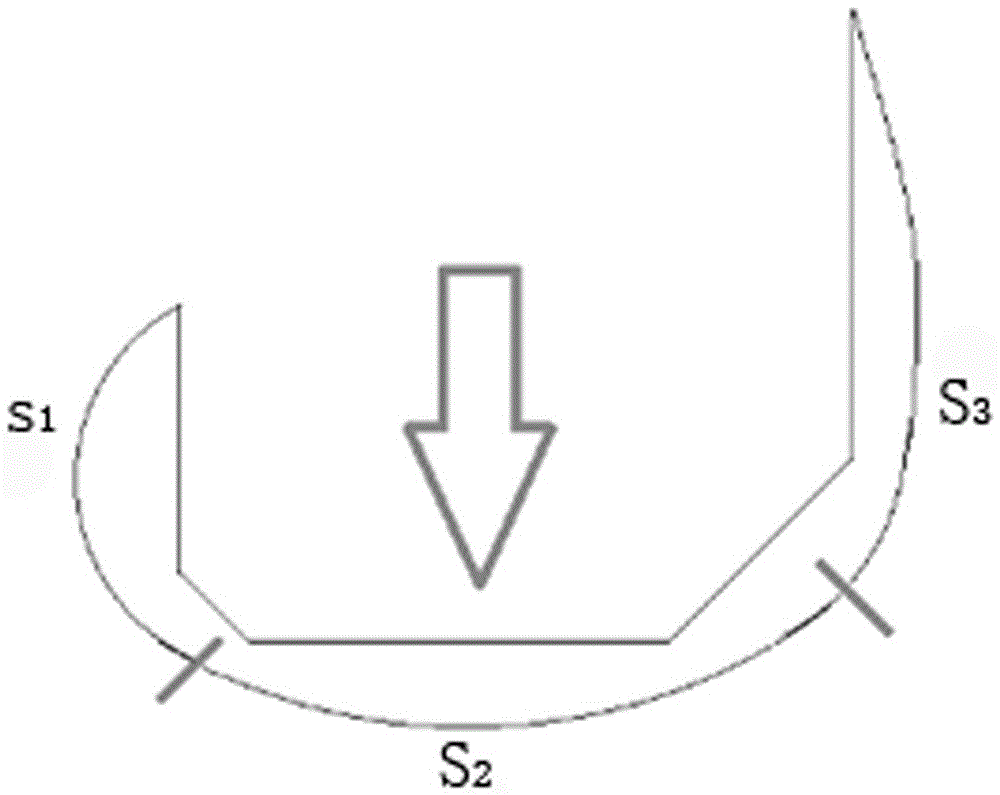

[0032] A method for designing a customized artificial knee joint prosthesis, comprising the following steps: (1) measuring the sagittal plane dimensions of the two condyles of the patient's femoral end through a CT image of the patient's femoral end, and then fitting the femur respectively according to the above-mentioned size data The first sagittal plane of the two condyles fits the ellipse; (2) Measure the coronal dimension of the two condyles on the horizontal plane of the patient's femoral end through the CT image of the patient's femoral end to obtain the coronal fitting ellipse of the two femoral condyles. Measure; (3) According to the size of the semi-minor axis of the fitting ellipse in the coronal plane of the two femoral condyles, reduce the first sagittal plane fitting ellipse corresponding to each coronal plane fitting ellipse by L to obtain the second femoral condyle. The bisagittal plane fits an ellipse, where L is equal to the length of the short semi-axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com