Dehumidification method capable of eliminating white smoke phenomena at return air shaft mouths

A return air shaft, air flow dehumidification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of difficult maintenance and management, high construction risk, and low atomization degree in the later stage, so as to facilitate later maintenance and management, Effect of eliminating visual pollution and high dehumidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

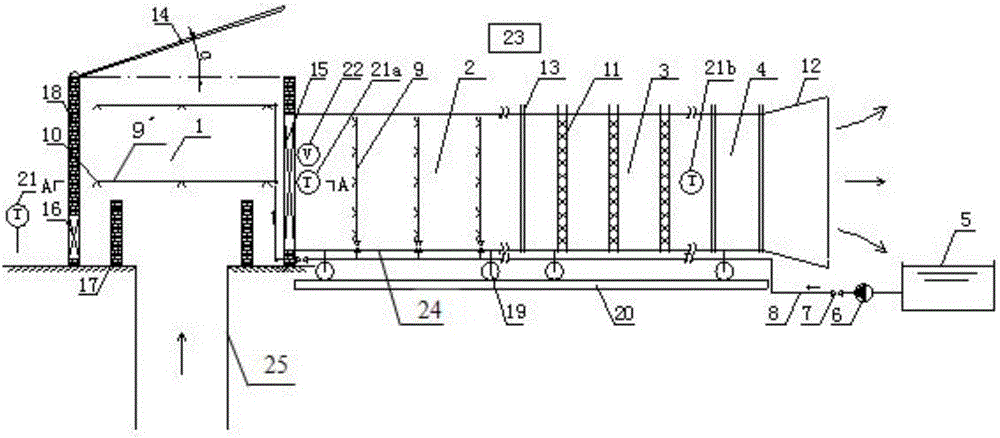

[0028] In order to further describe the present invention, a dehumidification method of the present invention capable of eliminating the phenomenon of white smoke at the wellhead of the return air will be further described in detail below in conjunction with the accompanying drawings and examples.

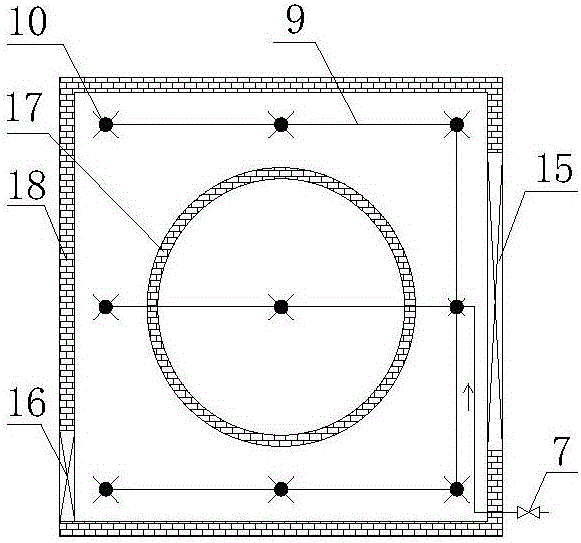

[0029] Have figure 1 The schematic diagram of the structural layout of the high-temperature saturated air flow dehumidification device adopted by the present invention is shown in conjunction with figure 2 It can be seen that the high-temperature saturated air flow dehumidification device adopted in a dehumidification method capable of eliminating the white smog phenomenon at the return air wellhead of the present invention is composed of a spray cooling system, a confluence area 1, an atomization area 2, a dehumidification area 3, and an outflow area 4 , sensors, and a PLC control system 23 connected to the sensors; the confluence area 1 is arranged above the shaft 1 of the retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com