Square workpiece clamping clamp module

A workpiece and component technology, which is applied in the field of fixture components for clamping square workpieces, can solve the problems of long auxiliary time and influence on processing efficiency, and achieve the effects of low cost, reliable operation and guarantee of normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

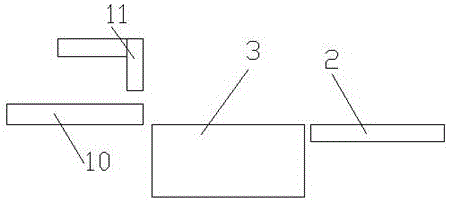

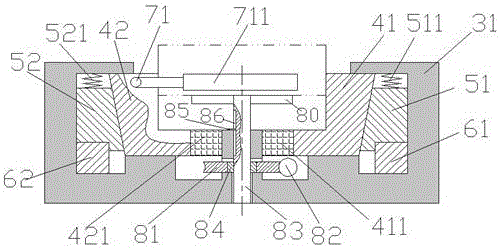

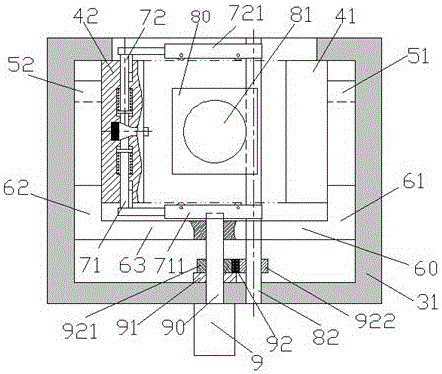

[0013] Combined in front Figure 1-4 The present invention will be described in detail.

[0014] A fixture assembly for clamping a square workpiece according to an embodiment, including a fixture assembly 3, characterized in that: the fixture assembly 3 includes a housing 31, and the middle part of the housing 31 is provided with a device that can be relatively close in the left and right directions and Two clamping blocks that are opposite to each other: a left clamping block 42 and a right clamping block 41, between the lower right extension of the left clamping block 42 and the housing 3, the right clamping block 41 A left spring 421 and a right spring 411 are respectively arranged between the lower left protruding part of the lower left part of the body and the housing 3, and a spring that can slide up and down is respectively arranged on the left side of the left clamping block 42 and the right side of the right clamping block 41. The left wedging block 52 and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com