Turning tool height positioner

A technology of height locator and turning tool, which is used in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., to achieve the effect of simple and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

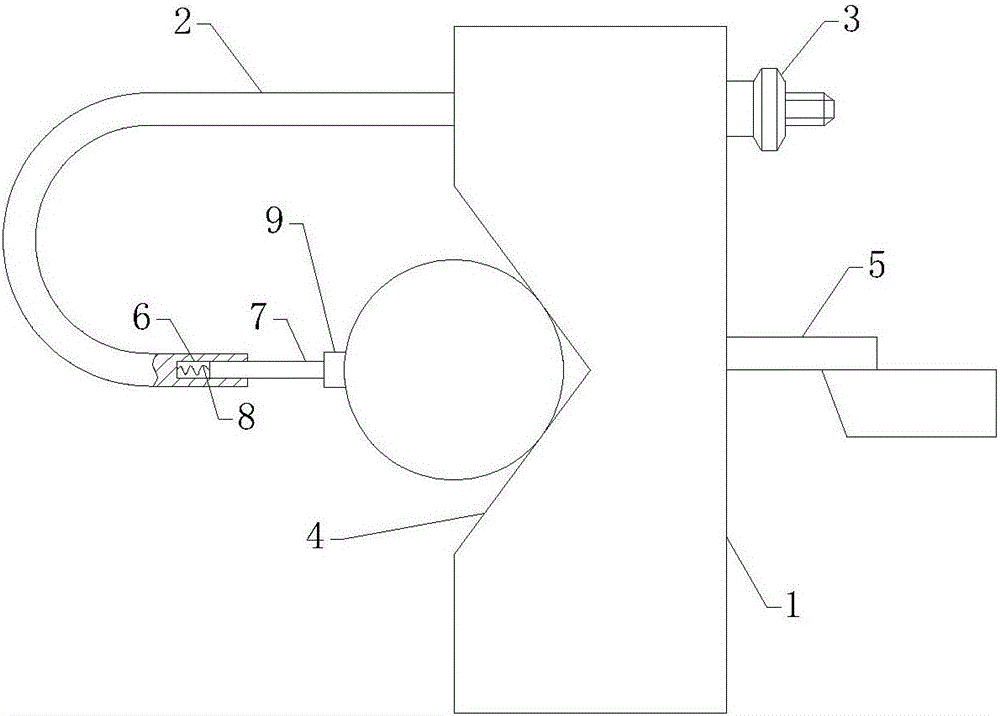

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the turning tool height locator of the present invention includes a base block 1, an elbow pull rod 2 and a knurled nut 3, a V-shaped groove 4 is provided on one side of the base block, and a tool setting pin 5 is provided on the other side, The lower generatrix of the tool setting pin coincides with the angle bisector of the V-shaped groove, and the tail of the elbow pull rod passes through the base block and is screwed with the knurled nut so as to complete the action of loosening and clamping the workpiece. When adjusting the tool, first use a square to align the bottom surface of the base block to be perpendicular to the base surface of the tool, then clamp the workpiece to be turned between the head end of the elbow tie rod and the V-shaped groove, and make the rotation center line of the workpiece in line with the V-shaped groove. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com