Foaming mold for improving quality of armrest

A foaming mold and quality technology, used in household appliances, other household appliances, applications, etc., can solve problems such as pores and material shortages, inability to guarantee product appearance, handrail surface defects, etc., to improve foaming, increase aesthetics, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

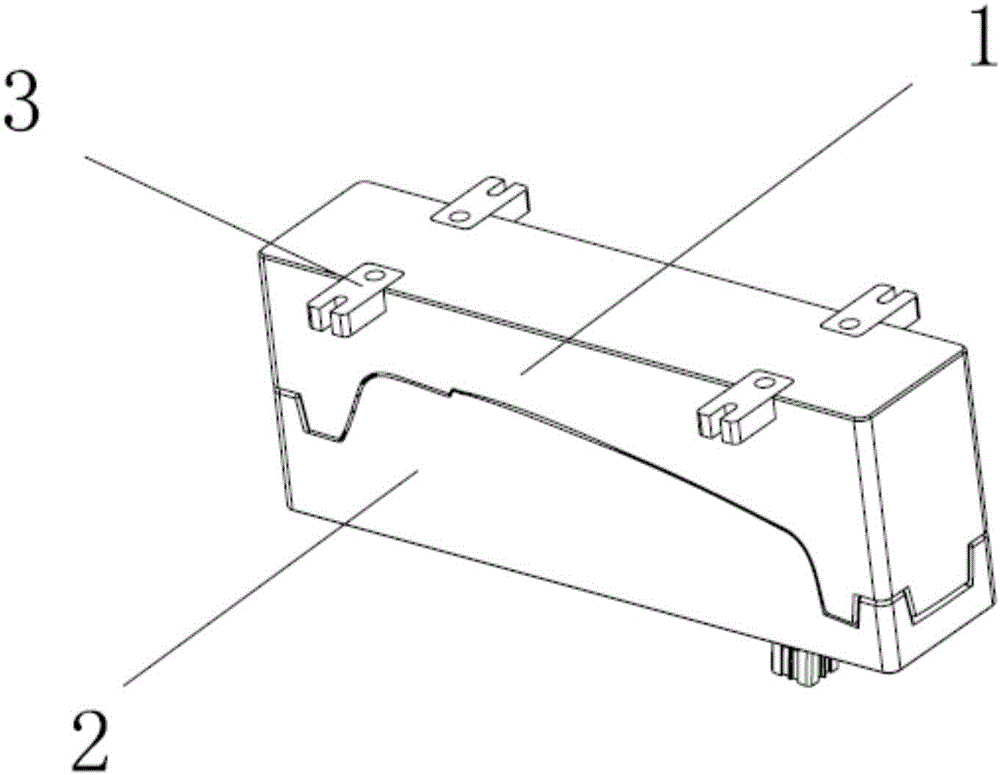

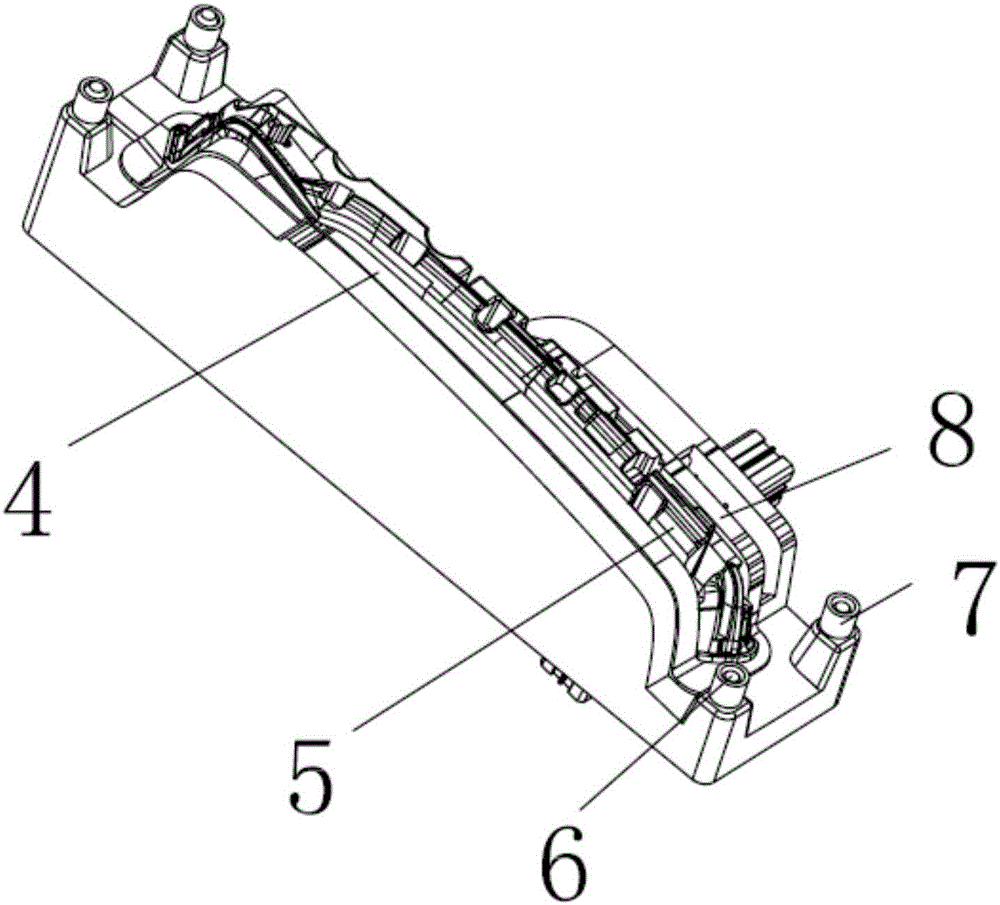

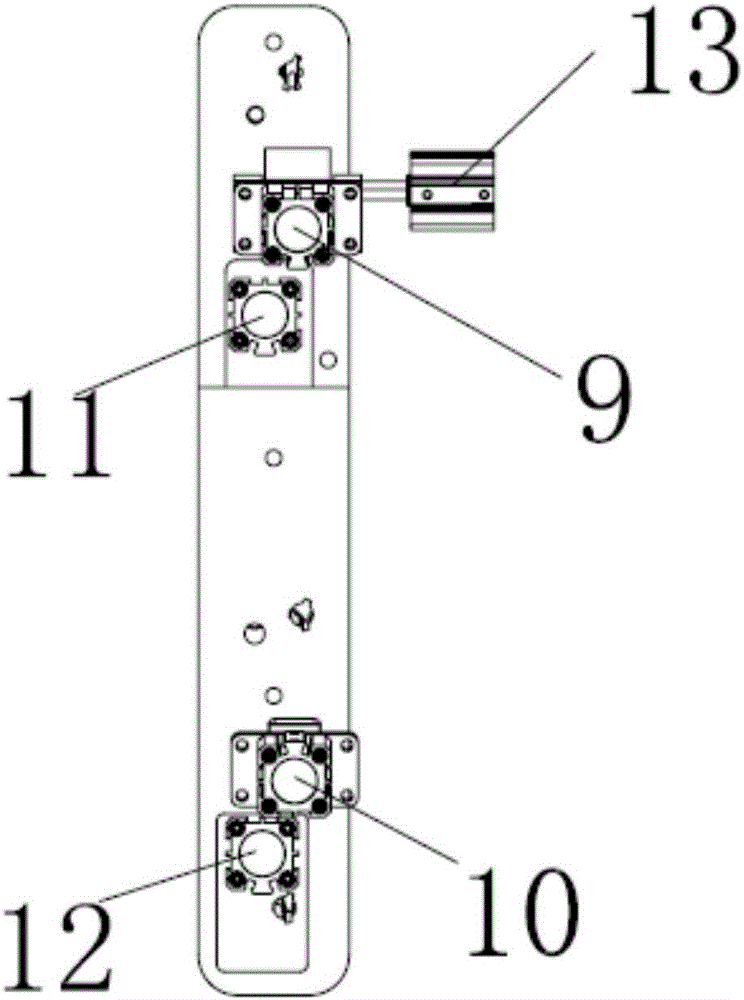

[0022] When it is necessary to perform foaming process on a batch of molds, first connect the entire mold with the mounting bracket through the connecting block 3, then insert the foam tube into the mold cavity, and then carry out mold fitting. After the mold fitting is completed, put the product On the front mold core 5 and the rear mold core 4, inject the set foam afterwards, start the front push cylinder 9 and the back push cylinder 10 at the same time, and the front push cylinder 9 and the back push cylinder 10 push the front mold core 5 and the back mold core 4. Simultaneously control the first core-pulling cylinder 11 and the second core-pulling cylinder 12 so that the core-pulling block is in contact with the foam, and then push the extrusion plate 8 to make the foam cavity smaller, making the foam layer more compact when forming, and then open the mold and take it out products, and replace them with new product rough embryos for the next production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com