Intelligent track-changeable rail guided vehicle and automatic warehouse

An automated warehouse and shuttle car technology, applied in the field of warehouse logistics, can solve the problems of guide rail spacing changes, difficulty in providing, and inability to realize track changes, etc., to achieve the effect of improving efficiency and improving the ability to handle parcels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

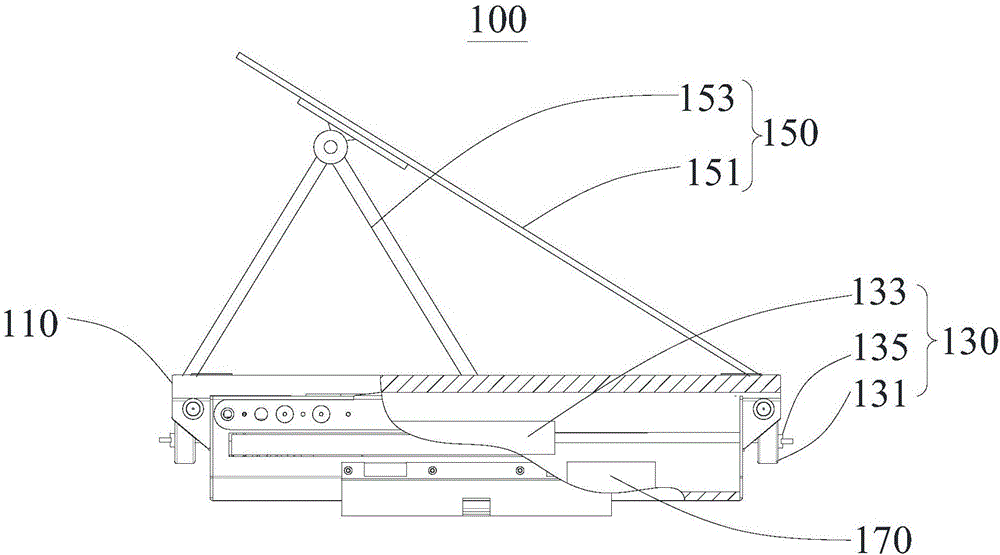

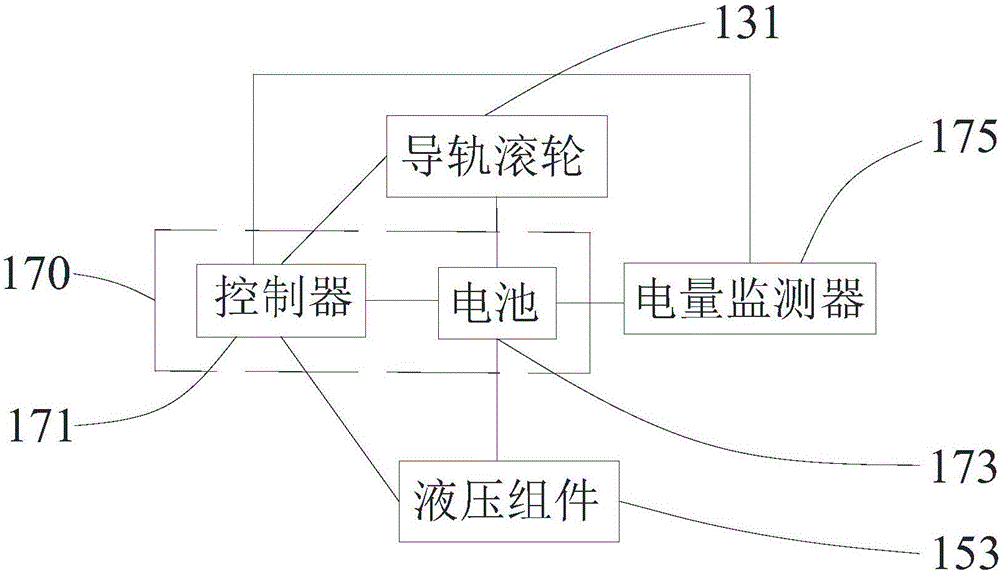

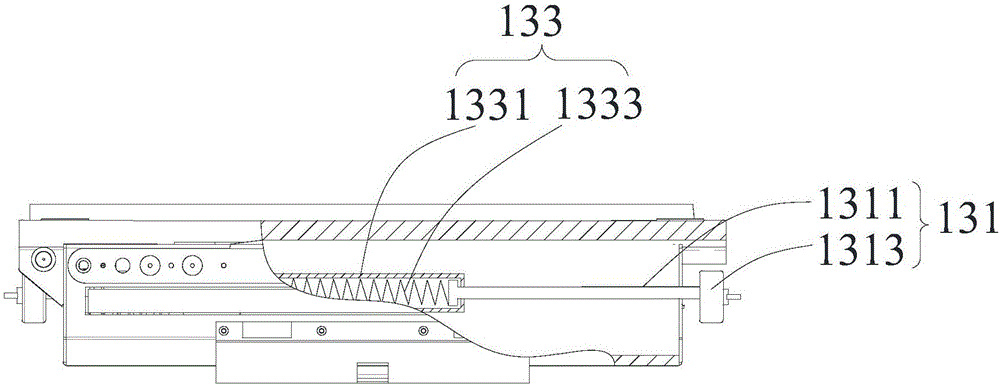

[0035] refer to figure 1 , the present embodiment provides an intelligent track-changing shuttle vehicle 100, which is used to slide on guide rails and transport parcels to designated areas. The intelligent track-changing shuttle vehicle 100 includes a car body 110, a plurality of rolling devices 130, a dumping device 150, The control device 170, a plurality of rolling devices 130 are arranged on the vehicle body 110 and abut against the guide rails, and are used to drive the vehicle body 110 to move. The dumping device 150 is embedded on the top surface of the vehicle body 110 . The electric control device 170 is arranged in the vehicle body 110 and electrically connected with the dumping device 150 and the rolling device 130 respectively.

[0036] The dumping device 150 includes a carrying plate 151 and a hydraulic assembly 153. One side of the carrying plate 151 is hinged on the car body 110 for carrying parcels. The hydraulic assembly 153 is connected with the carrying pl...

no. 2 example

[0051] see Figure 5 , the present embodiment provides an automated warehouse 200 for storing parcels. The automated warehouse 200 includes shelves (not shown), stackers (not shown), guide rails (not labeled), parcel collection equipment 210 and The smart track-changing shuttle car 100, wherein the basic structure and principle of the smart track-changing shuttle car 100 and the technical effects produced are the same as those of the first embodiment. For a brief description, the part not mentioned in this embodiment can refer to the first embodiment corresponding content in the example. The guide rail is used to connect the storage entrance and the package collection equipment 210. The intelligent rail-changing shuttle 100 is slidably connected to the guide rail through the rolling device 130. The package collection equipment 210 is fixed at the end of the guide rail. The stacker is set at a distance from the package collection equipment 210 On one side of the guide rail, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com