An integrated detection system for highways

A detection system and road technology, applied in the direction of measuring devices, vehicle testing, force/torque/power measuring instruments, etc., can solve the problem of low braking force measurement accuracy, avoid inter-dimensional coupling, avoid braking force and lateral The effect of sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

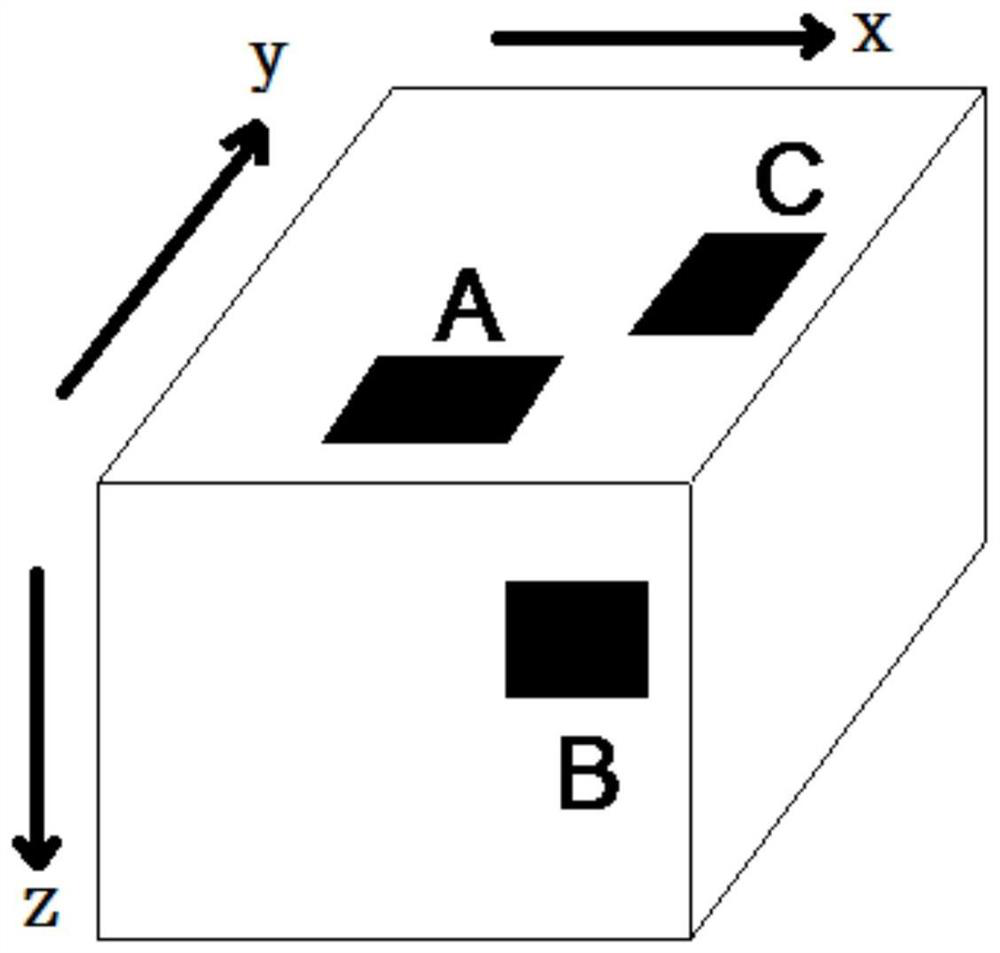

[0048] This embodiment provides an integrated detection system for roads, including: at least one three-dimensional combined force measuring device, the three-dimensional combined force measuring device is used to detect the braking force and vehicle weight of a motor vehicle;

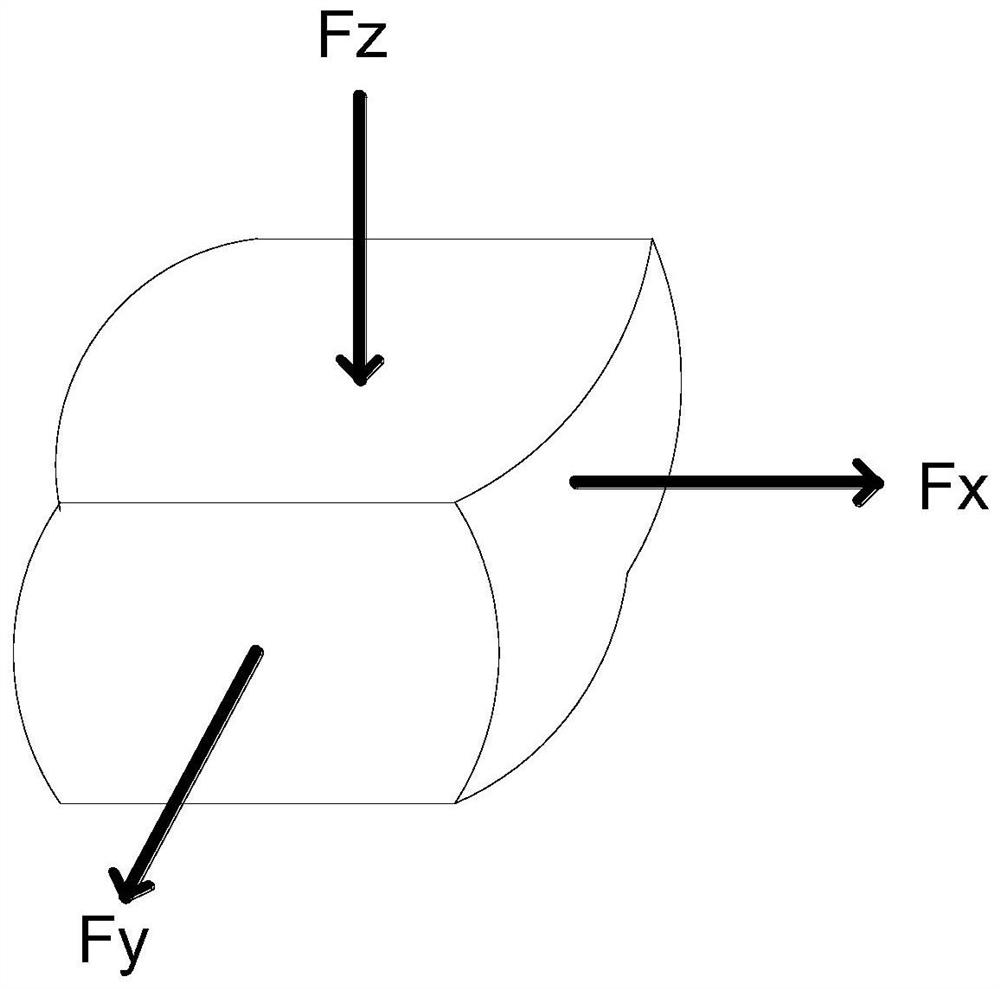

[0049] The three-dimensional combined force measuring device includes: a table top 1, which is a cube; several horizontal sensors are installed below the table top 1 and parallel to the horizontal side length of the table top 1; several vertical sensors 2 are vertically installed on the table top 1 below; a horizontal connecting bracket 8 with a mounting through hole, and a horizontal connecting bracket 8 is respectively provided at both ends of each of the level sensors, and the horizontal sensor and the mounting through hole can only be around the axis of the mounting through hole The horizontal connection bracket 8 is fixedly connected with the table 1 through the rotation fit connection.

[0050] T...

Embodiment 2

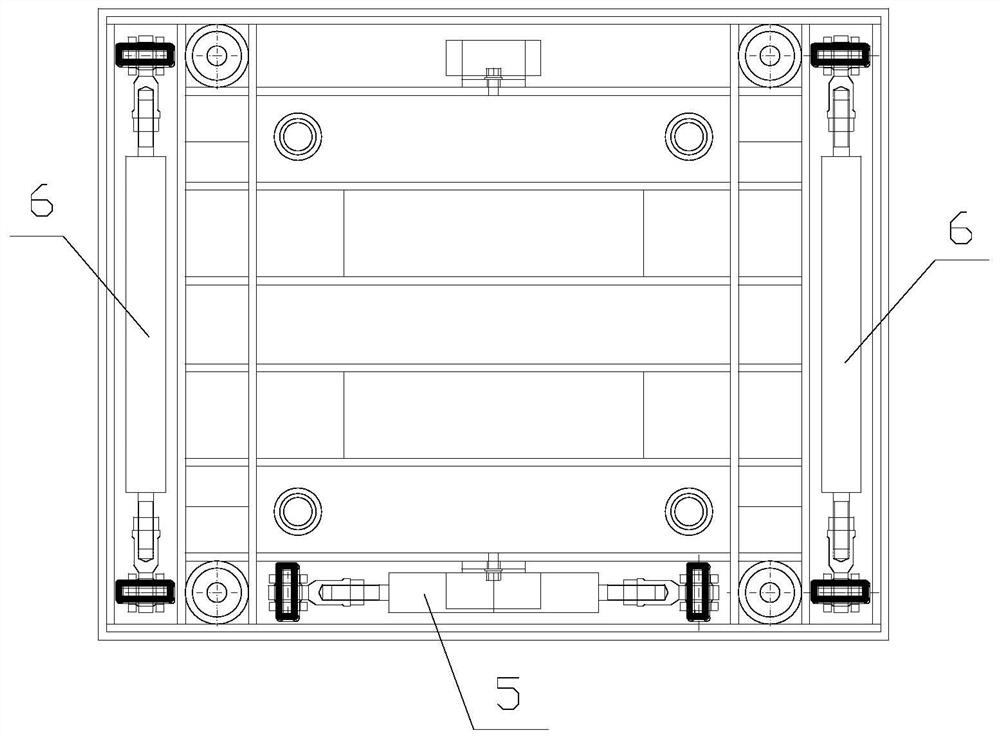

[0068] In this embodiment, it is made on the basis of embodiment 1, such as image 3 with 4 As shown, a rib 7 perpendicular to the table 1 is fixed under the table 1 in the three-dimensional combined force measuring device, and the horizontal connecting bracket 8 is fixedly connected to the rib 7 .

[0069] At the same time, if Figure 5 As shown, the three-dimensional combined force measuring device provided in this embodiment also includes vertical connection bearings 3 arranged at both ends of the vertical sensor 2, and the vertical sensor 2 can only be wound around the vertical connection bearing 3 The axis rotates, and the vertical connection bearing 3 arranged on the top is fixedly connected with the table 1.

[0070] Through the vertical connection bearing 3, the deformation of the table 1 along the horizontal direction can be resolved, so that the vertical sensor 2 can only monitor the force in the vertical direction, which is conducive to improving measurement accur...

Embodiment 3

[0081] This embodiment is made on the basis of Embodiment 1 and Embodiment 2, wherein the horizontal connection bracket 8 and the vertical connection bearing 3 are joint bearings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com