Drive transmission mechanism and image forming apparatus therewith

A transmission mechanism and driving force technology, which is applied in the field of drive transmission mechanism and image forming device, can solve the problems of gear rotation fluctuation, gear surface inclination (collapse, reduction of rigidity of drive transmission mechanism, etc.), and achieve the effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

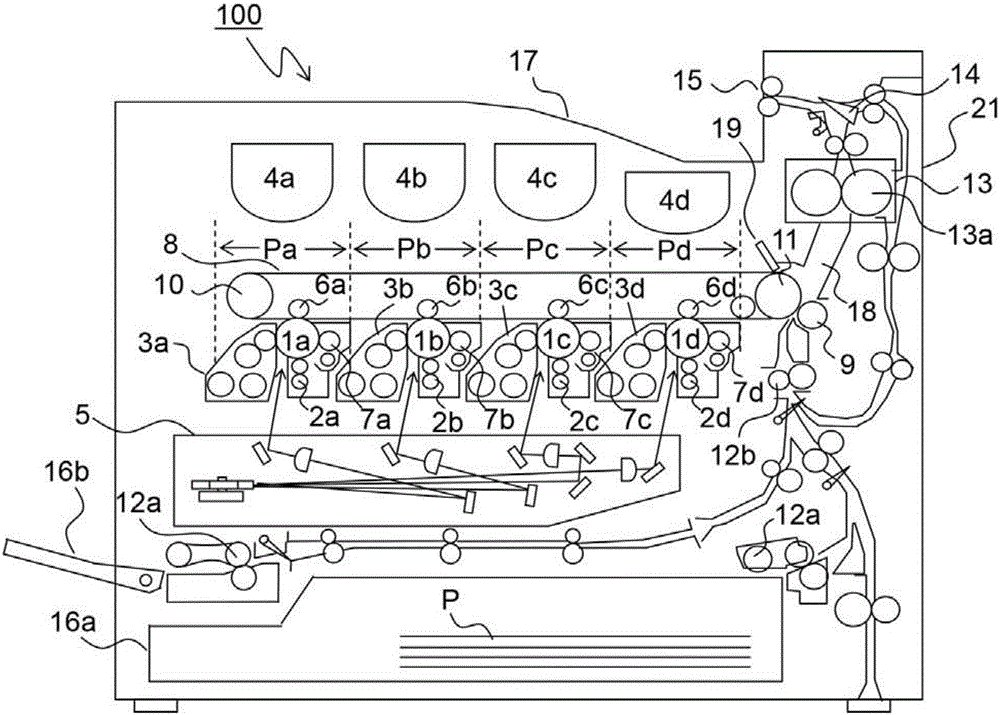

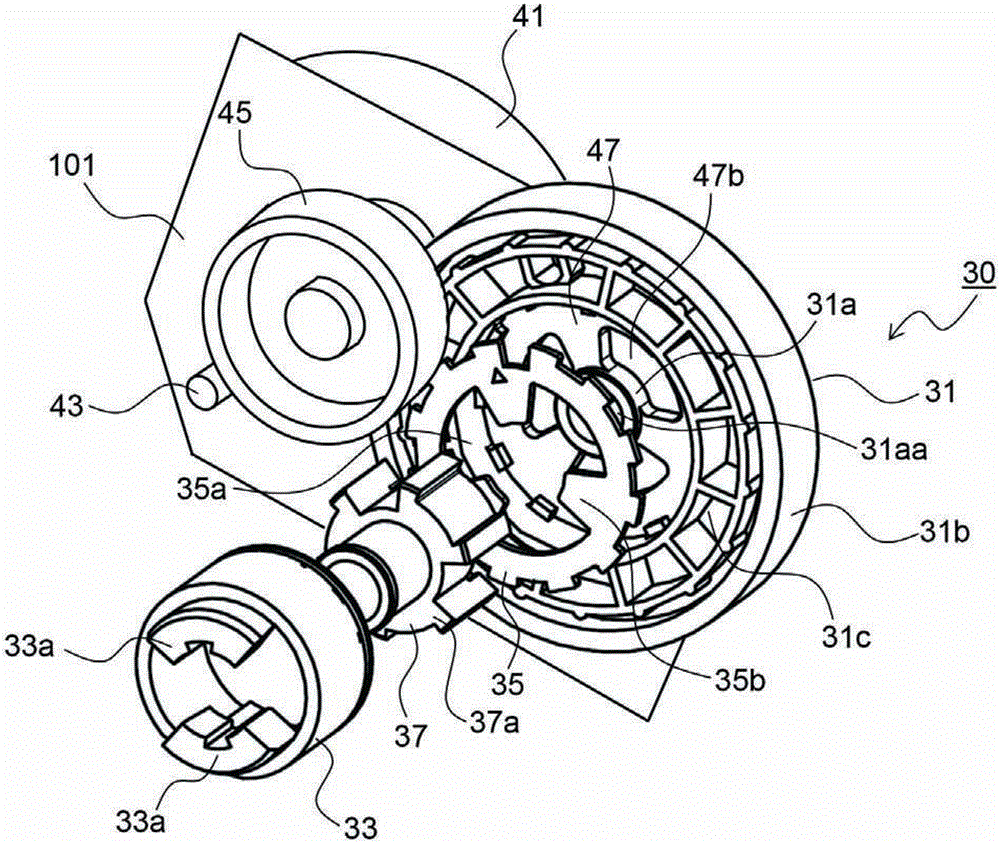

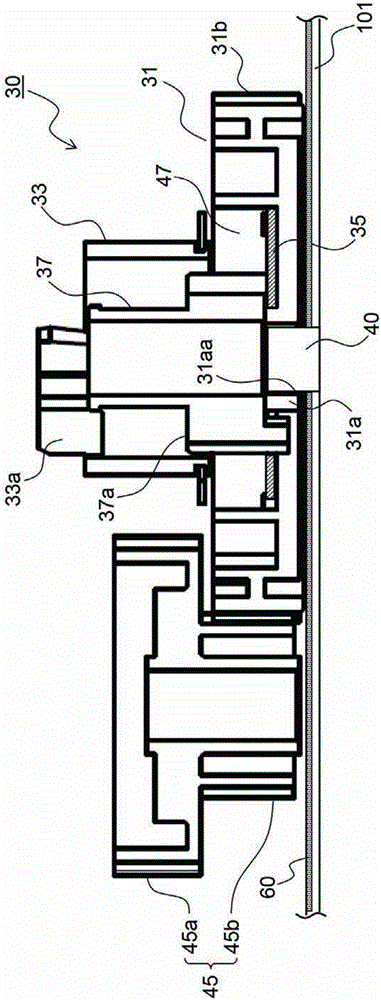

[0021] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a schematic cross-sectional view showing the internal structure of the color printer 100 including the drive transmission unit 30 of the present invention. The color printer 100 is a tandem type. In the main body of the color printer 100, the four image forming sections Pa, Pb, Pc, and Pd correspond to images of four different colors (cyan, magenta, yellow, and black). upstream side ( figure 1 The left side in ) are configured in sequence.

[0022] Photosensitive drums 1a, 1b, 1c, and 1d carrying visible images (toner images) of various colors are disposed in these image forming portions Pa to Pd, and are driven around by driving means (not shown). figure 1 The intermediate transfer belt 8 rotating in the counterclockwise direction is provided adjacent to the respective image forming portions Pa to Pd. Make the photosensitive drums 1a-1d around figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com