Elevator anti-skid floor

A non-slip floor and elevator technology, which is applied to elevators, transportation and packaging in buildings, can solve the problems of poor appearance and large pattern spacing, and achieve the effect of avoiding discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

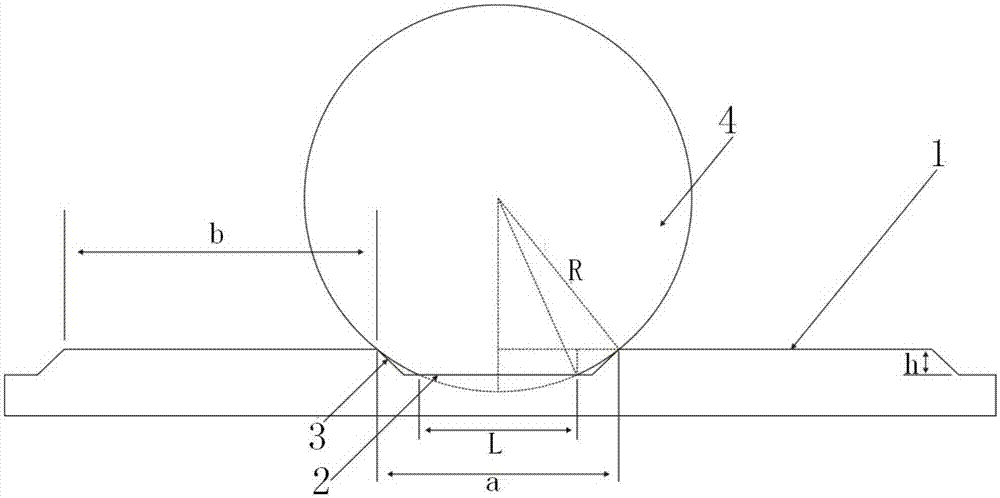

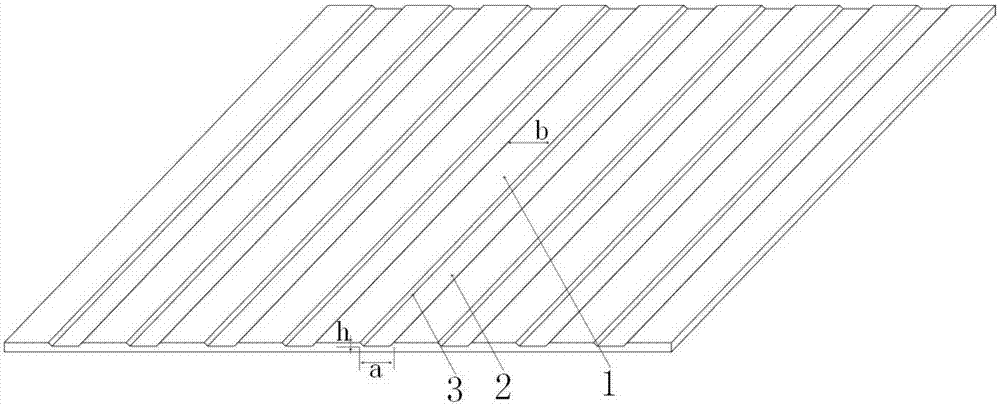

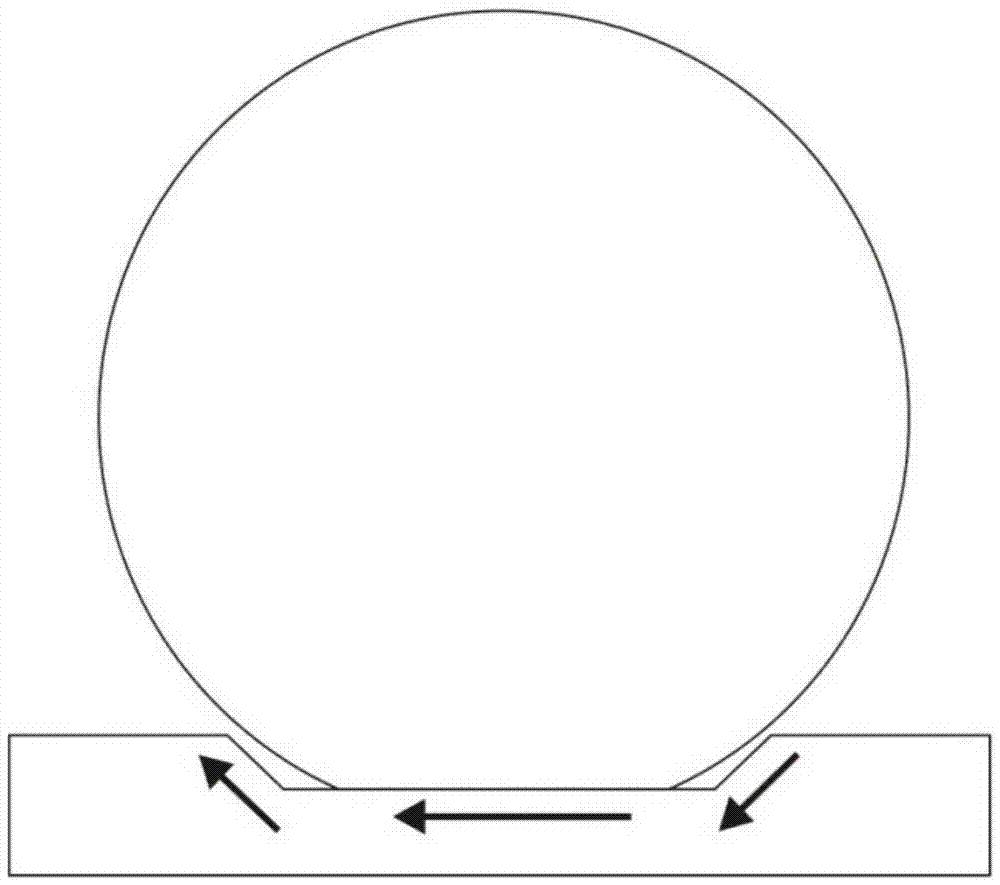

[0021] The elevator anti-slip floor provided by the invention, such as figure 2 As shown, it includes several first load-bearing surfaces 1 and several second load-bearing surfaces 2, wherein the first load-bearing surfaces 1 are higher than the second load-bearing surfaces 2, and the first load-bearing surfaces 1 and second load-bearing surfaces 2 are arranged in stripes at intervals And the arrangement direction is consistent with the direction of entering and exiting the elevator (equivalent to the extension direction of the first bearing surface 1 and the second bearing surface 2 being perpendicular to the direction of entering and exiting the elevator), the adjacent first bearing surface 1 and the second bearing surface 2 pass through the slope The surface 3 is connected to realize the continuous transition between the first loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com