Preparation process of tea beverage

A preparation process and technology for tea beverages, applied in the field of food processing, can solve the problems of high energy consumption and other problems, and achieve the effects of promoting dissolution, good clarification effect, and clear tea liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

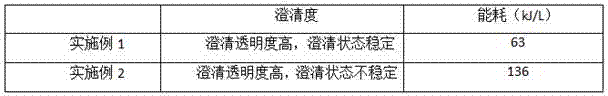

Examples

Embodiment 1

[0019] The application provides a preparation process for tea beverage, comprising the following steps:

[0020] Step 1. Extraction: put fresh tea leaves and pectinase into deionized water together, extract at 2.1~.2.5MPa, 85°C for 15min, the mass ratio of tea leaves, pectinase and deionized water is 1:0.08 : 9, the pH of deionized water is 6.7~7.2.

[0021] Step 2, coarse filtration: after adjusting the temperature of the extract solution to 80°C, perform coarse filtration to obtain a coarse filtrate.

[0022] Step 3, clarification treatment: add 1 gram of citric acid powder to every 6 milliliters of crude filtrate, and add them together into a centrifuge at a speed of 700 r / min, centrifuge for 2 minutes, and then let stand for 10 minutes.

[0023] Step 4, blending: blending the taste of the tea beverage to obtain a blended liquid.

[0024] Step 5, fine filtration: After the preparation liquid is naturally cooled and lower than 75°C, fine filtration is performed with a doub...

Embodiment 2

[0028] A traditional tea beverage preparation process is adopted, comprising the following steps;

[0029] Step 1, extraction: mix tea leaves and water at a mass ratio of 1:10, and extract at 85°C for 20 minutes;

[0030] Step 2, coarse filtration: coarsely filter the extract to obtain a coarse filtrate;

[0031] Step 3, cooling: cooling the crude filtrate to 5°C;

[0032] Step 4, fine filtration: perform fine filtration on the cooled coarse filtrate;

[0033] Step 5, blending: blending the taste of the tea beverage according to the preset ratio to obtain the blended liquid;

[0034] Step 6. Sterilization: Sterilize at 100°C for 2 minutes;

[0035] Step 7. Filling and capping: Fill and cap with a 500ml plastic bottle before selling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com