Anti-rust welding wire

A technology of welding wire and anti-rust paper, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of loss of welding wire production enterprises, affecting the welding process performance of welding wire, and difficulties in production and organization of welding wire enterprises. The effect of avoiding the rust of the welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the drawings.

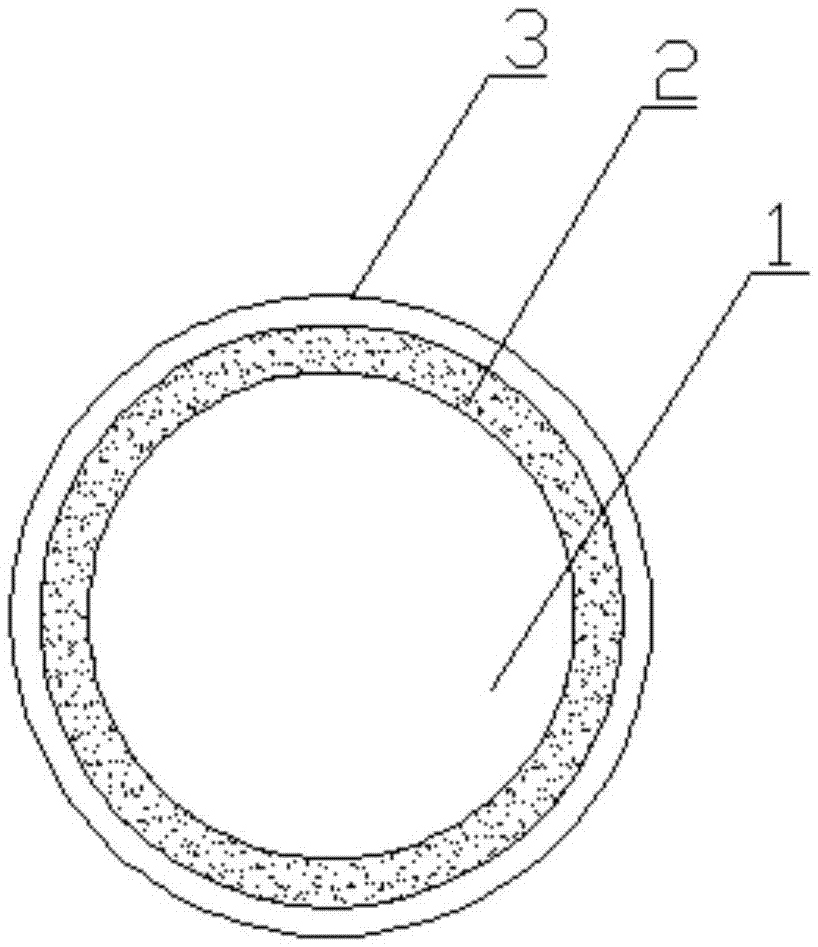

[0011] Such as figure 1 As shown, an anti-rust welding wire of the present invention includes a welding wire body 1, an olive oil film layer 2 is coated on the outside of the welding wire body 1, and an anti-rust paper layer 3 is provided outside the olive oil film layer 2. The layer 3 wraps the entire welding wire body 1, and the olive oil film layer 2 has a thickness of 0.1-0.3 mm.

[0012] The working process of this example: the outside of the welding wire body 1 is coated with an olive oil film layer 2 to isolate the welding wire body 1 from the air, the rust-proof paper layer 3 wraps the entire welding wire body 1, and both ends of the welding wire body are also wrapped in it. The welding wire body 1 is further protected to effectively prevent the welding wire from rusting, and the rust-proof paper layer 3 can be stripped off during use.

[0013] An embodiment of the present inv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap