Automatic deburring machine

An automatic technology, applied in the field of automatic front-removing machine, can solve the problems of affecting the processing of workpieces, unable to meet modern production, low work efficiency, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

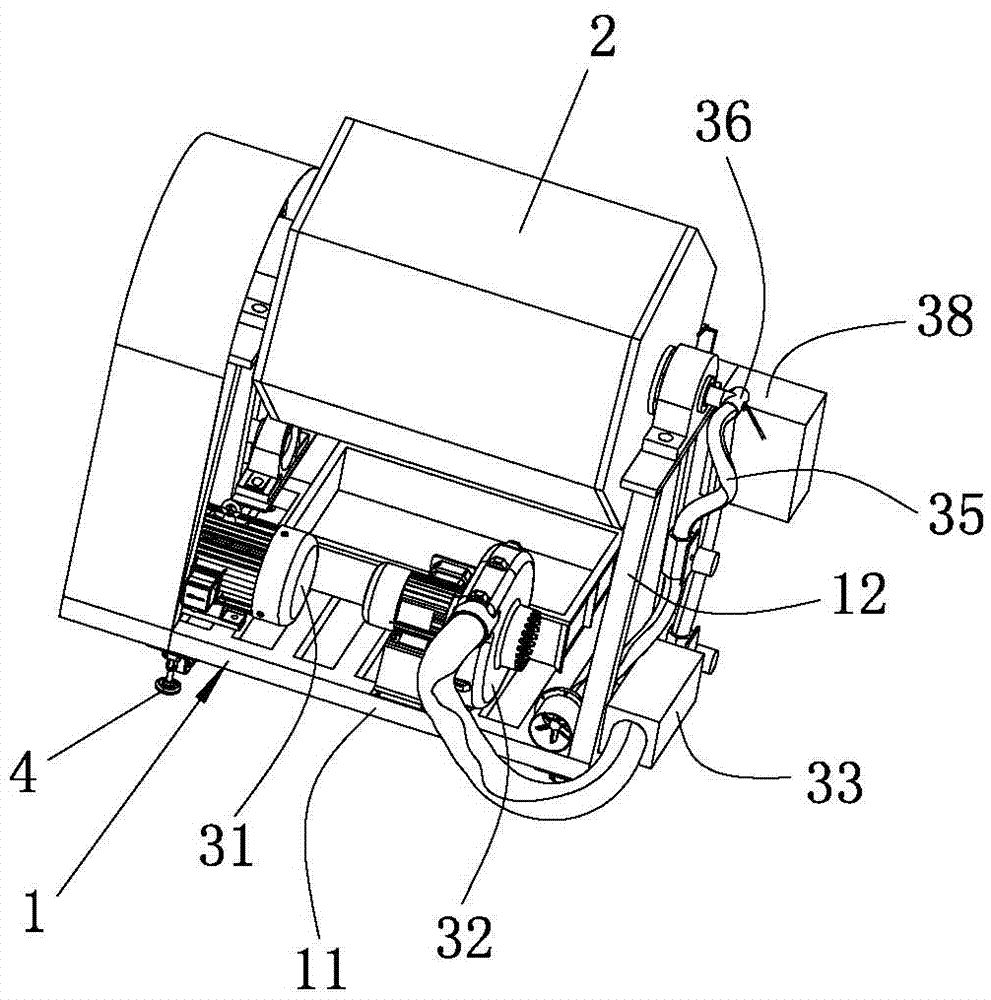

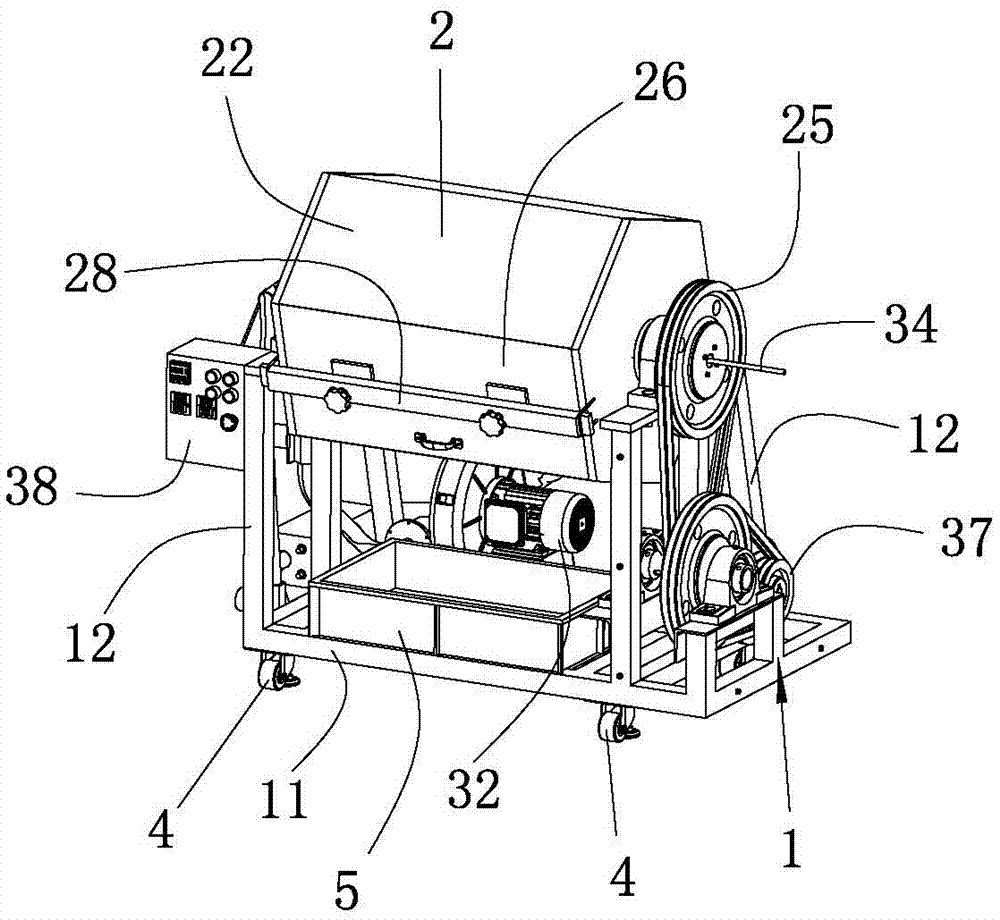

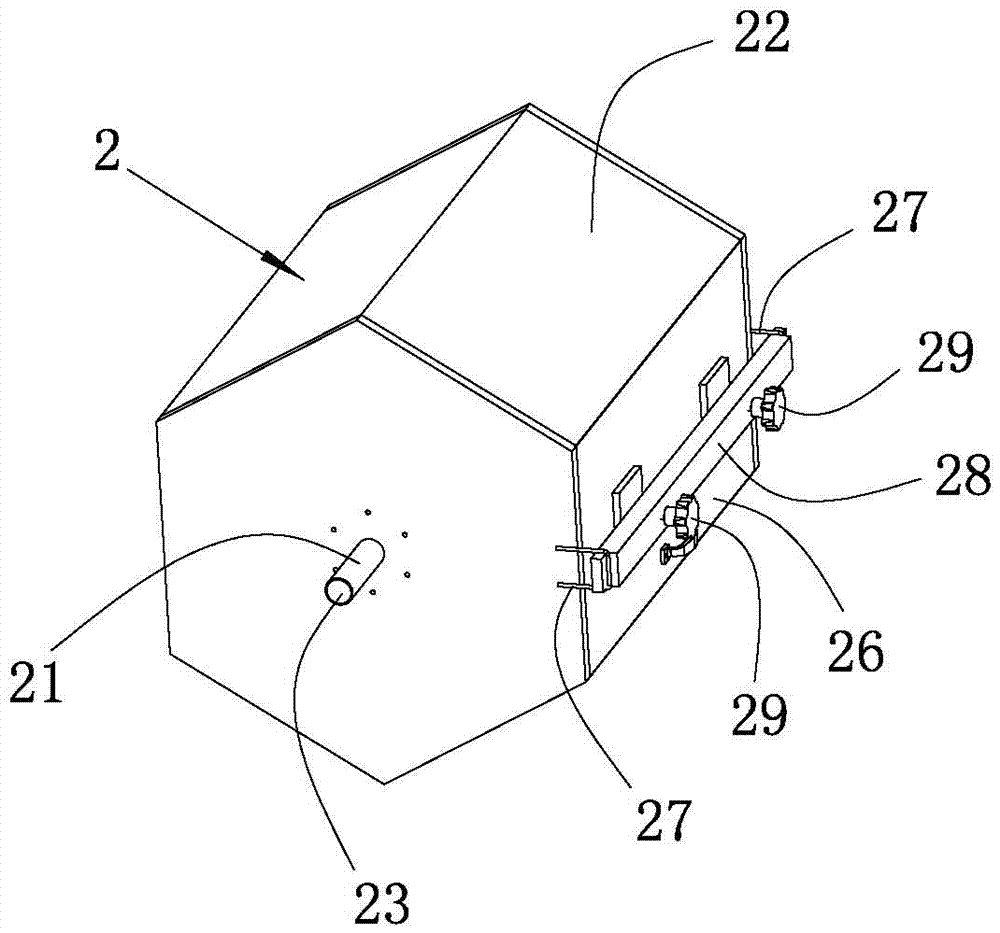

[0031] see Figure 1 to Figure 4 , a kind of automatic decapitation machine of the present invention, comprises frame body 1, cylinder 2 and drive member 31, frame body 1 adopts metal material to make, as carbon steel etc., and cylinder 2 includes rotatably connected on the frame body 1 The shaft body 21 and the cylinder body 22 installed on the shaft body 21, in this embodiment, the two ends of the shaft body 21 are respectively hinged on the frame body 1, and the shaft body 21 is sleeved with two bearings spaced from each other. The bearing is installed on the frame body 1, and the driving part 31 is installed on the frame body 1. The driving part 31 is used to drive the shaft bod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap