One of the burrs that can adapt to a multi -length rubber spring removal device

A technology of burr removal and rubber spring, applied in the field of rubber shock absorbers, can solve the problems of cumbersome process, scratching the outer surface of the rubber, breaking the rubber strip, etc., so as to improve the processing efficiency and prevent the scratching phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

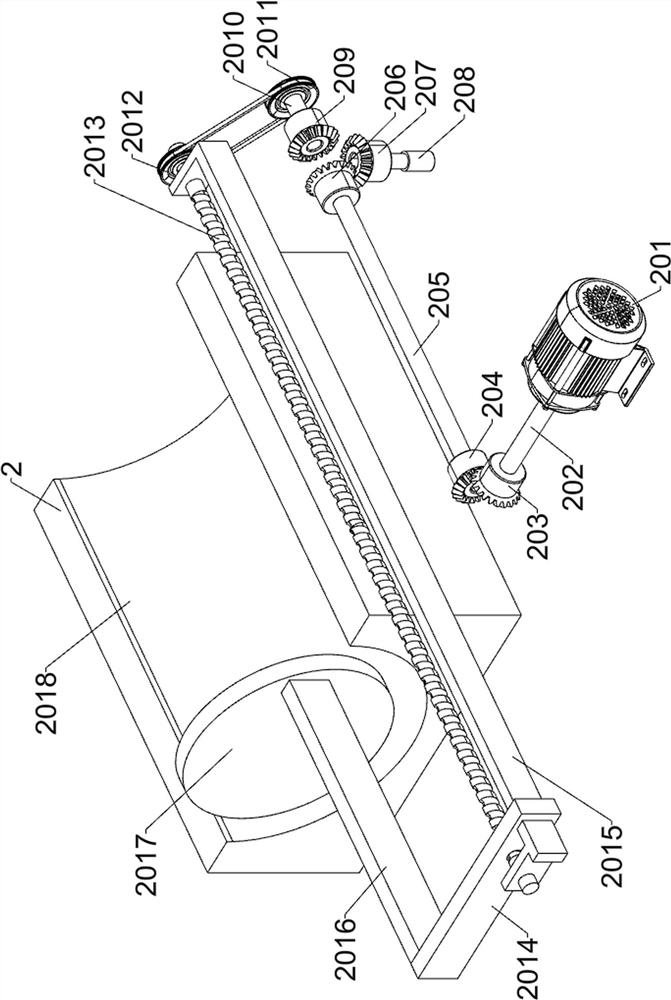

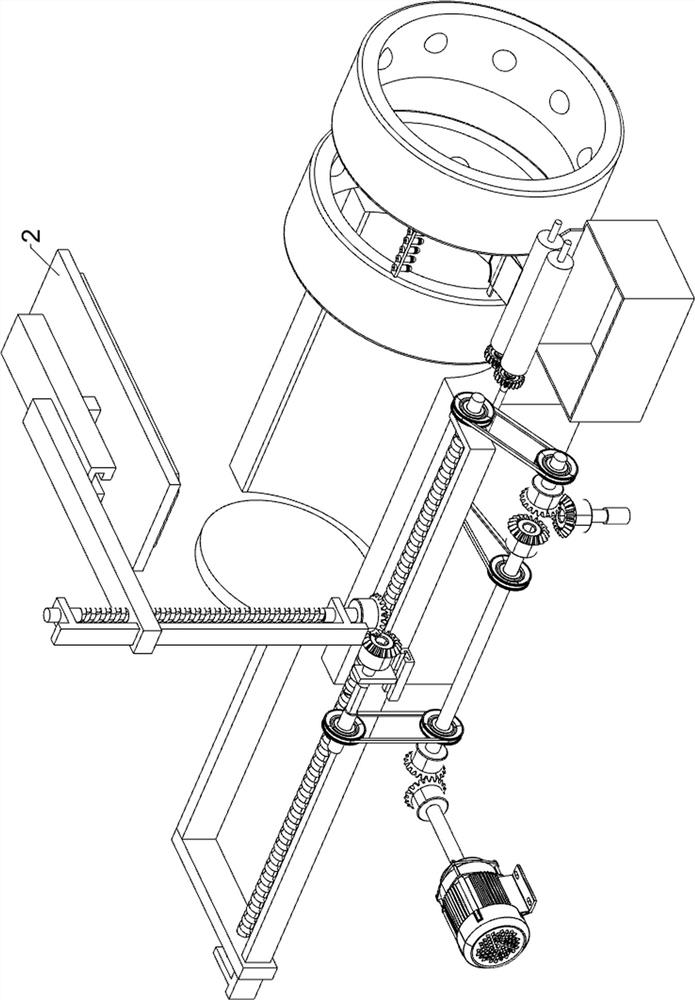

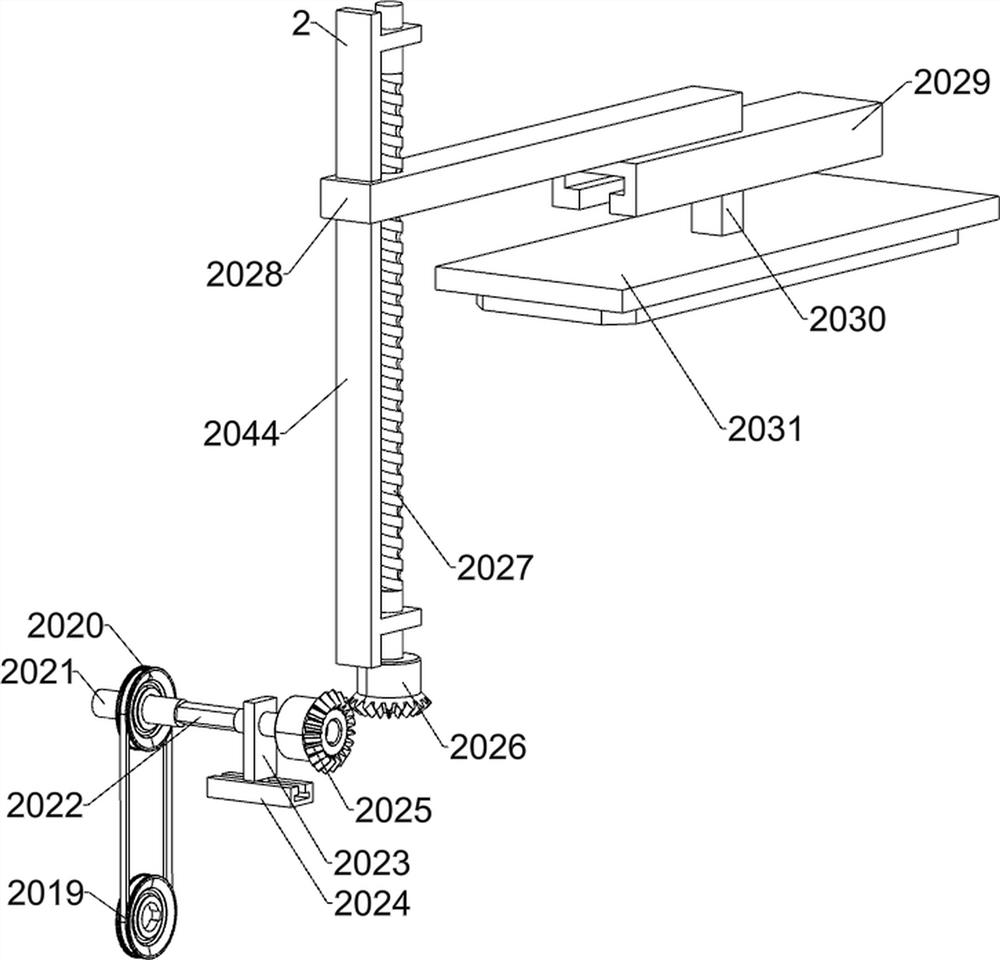

[0029] A burr removal device that can adapt to rubber springs of various lengths, such as Figure 1-8 As shown, it includes a chassis 1, an outer ring surface burr removal component 2, a transport component 3, an inner ring surface burr removal component 4 and a control panel 5; the chassis 1 is connected with the outer ring surface burr removal component 2; the chassis 1 is connected with The transport assembly 3 is connected; the chassis 1 is connected with the inner ring burr removal assembly 4; the top of the chassis 1 is connected with the control panel 5; the outer ring surface burr removal assembly 2 is connected with the transportation assembly 3; the transportation assembly 3 is connected with the inner ring The burr removal assembly 4 is connected.

[0030] When preparing for work, place the device on a horizontal surface, turn on the power supply, put the composite rubber spring to be processed into the outer ring surface burr removal assembly 2 laterally, and opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com